High-sensitivity biosensor produced via nanoparticle technology and production method thereof

A biosensor and high-sensitivity technology, which is applied in the field of high-sensitivity biosensors and its preparation, can solve the problems of reducing sensor sensitivity, consuming large samples, and high oxidation potential, and achieve the effects of eliminating adverse effects, reducing detection time, and increasing sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

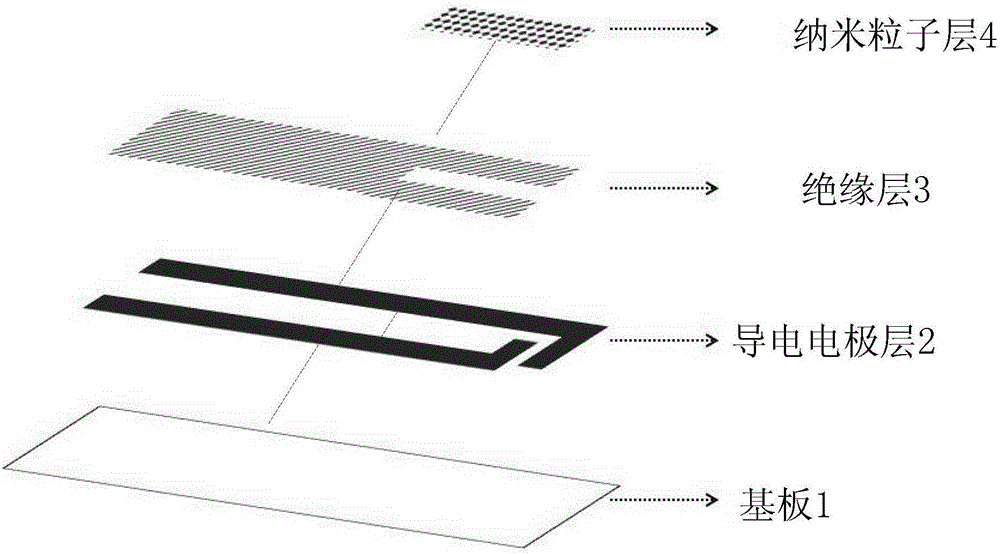

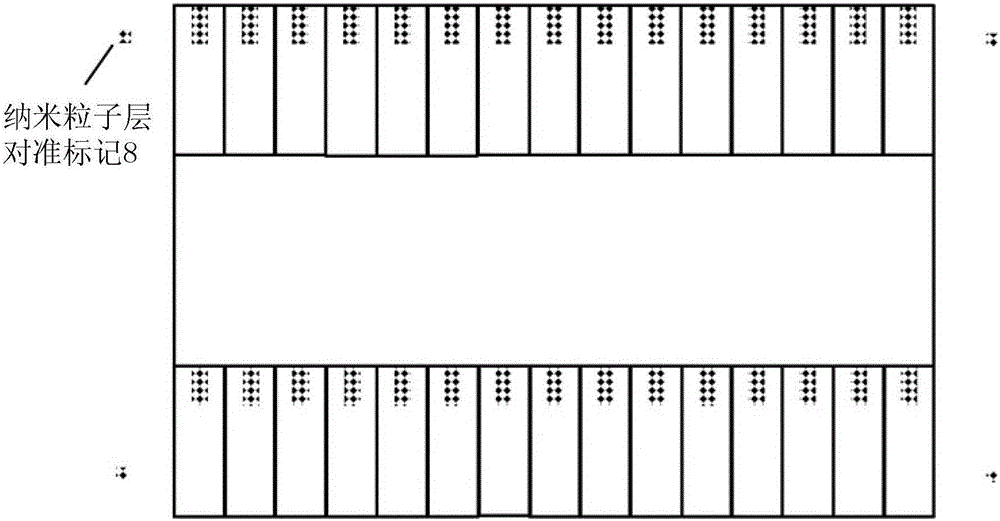

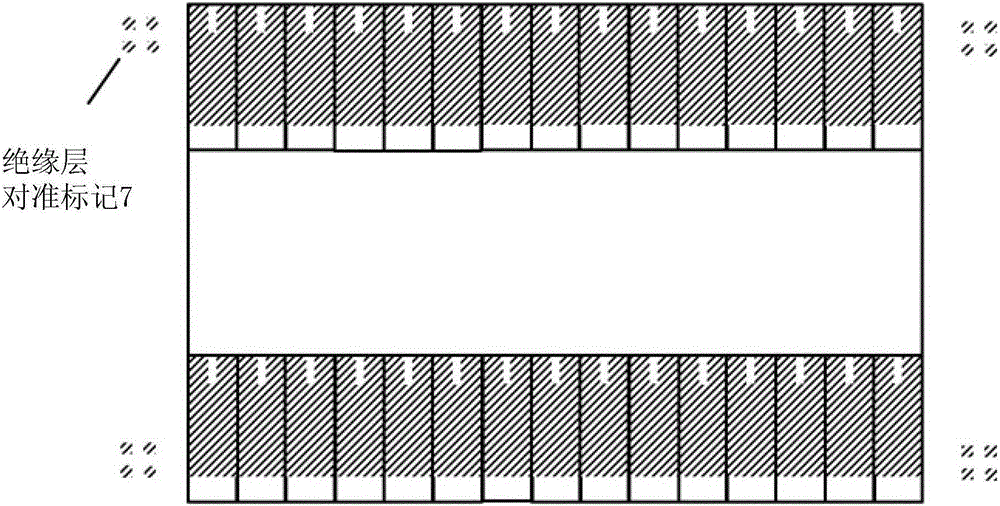

[0037] The invention provides a kind of high-sensitivity biosensor prepared by means of nanoparticle technology and a preparation method thereof, based on the method, the biosensor is prepared as a nanoparticle-enzyme biosensor microchip, such as figure 1 , figure 2 , image 3 As shown, the high-sensitivity biosensor consists of a plastic substrate 1, and the conductive electrode layer 2, insulating layer 3 and nanoparticle layer 4 on its surface can be deposited by screen printing technology using corresponding ink and chemical substances respectively. The specific preparation process of the high-sensitivity biosensor is as follows: Figure 4 As shown, firstly, two electrodes are screen-printed on the surface of the plastic substrate, one of which is the working electrode and the other is the counter electrode, forming a conductive metal or non-metal electrode layer, and the two electrodes are separated by a small gap. Then print a layer of non-conductive insulating layer ...

Embodiment 1

[0064] This embodiment provides a method for preparing a high-sensitivity biosensor by means of nanoparticle technology, which specifically includes the following steps:

[0065] Step 1: Pretreatment of the plastic substrate, before pretreatment, cut a polyvinyl chloride (PVC) substrate with a size of 1500 mm × 1500 mm into 18 cm × 10 cm. Place the PVC base plate between two symmetrical stainless steel plates and press from both sides. The polyvinyl chloride substrate together with the stainless steel plate was placed in a 70°C oven for 30 minutes and allowed to cool in the atmosphere. The operation was repeated so that a flat polyvinyl chloride substrate was obtained and thermal stress was removed to prevent the substrate from warping. Remove the stainless steel plate from the PVC substrate.

[0066] Step 2: Weigh a sufficient amount of conductive ink and mix it with the corresponding solvent (if any), such as carbon paste, silver and palladium can be mixed with thinner, re...

Embodiment 2

[0071] This implementation provides a method for preparing a high-sensitivity biosensor by means of nanoparticle technology, which specifically includes the following steps:

[0072] Step 1: Pretreat the plastic substrate, which is made of polyester sheet (PET), with a size of 210mm×297mm. Before pretreatment, cut the polyester sheet substrate into a suitable size of 18cm×10cm. The PET substrate was placed between two symmetrical stainless steel plates and pressed from both sides. The polyester sheet substrate together with the stainless steel plate was placed in a 90°C oven for 30 minutes and allowed to cool in the atmosphere. Repeat the above operations in order to obtain a flat polyester sheet substrate and remove thermal stress to prevent the substrate from bending. Remove the stainless steel plate from the polyester sheet substrate.

[0073] Step 2: Weigh a sufficient amount of conductive ink and mix it with the corresponding solvent (if any), such as carbon paste, silv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com