Transparent conductive film and manufacturing method therefor, and touch screen

A technology of transparent conductive film and production method, which is applied in the direction of transparent dielectric, printed circuit manufacturing, conductive pattern formation, etc., can solve the problem of non-bending, inability to meet small quantity, variety, low-cost and rapid manufacturing, unfavorable industrial production and sales, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

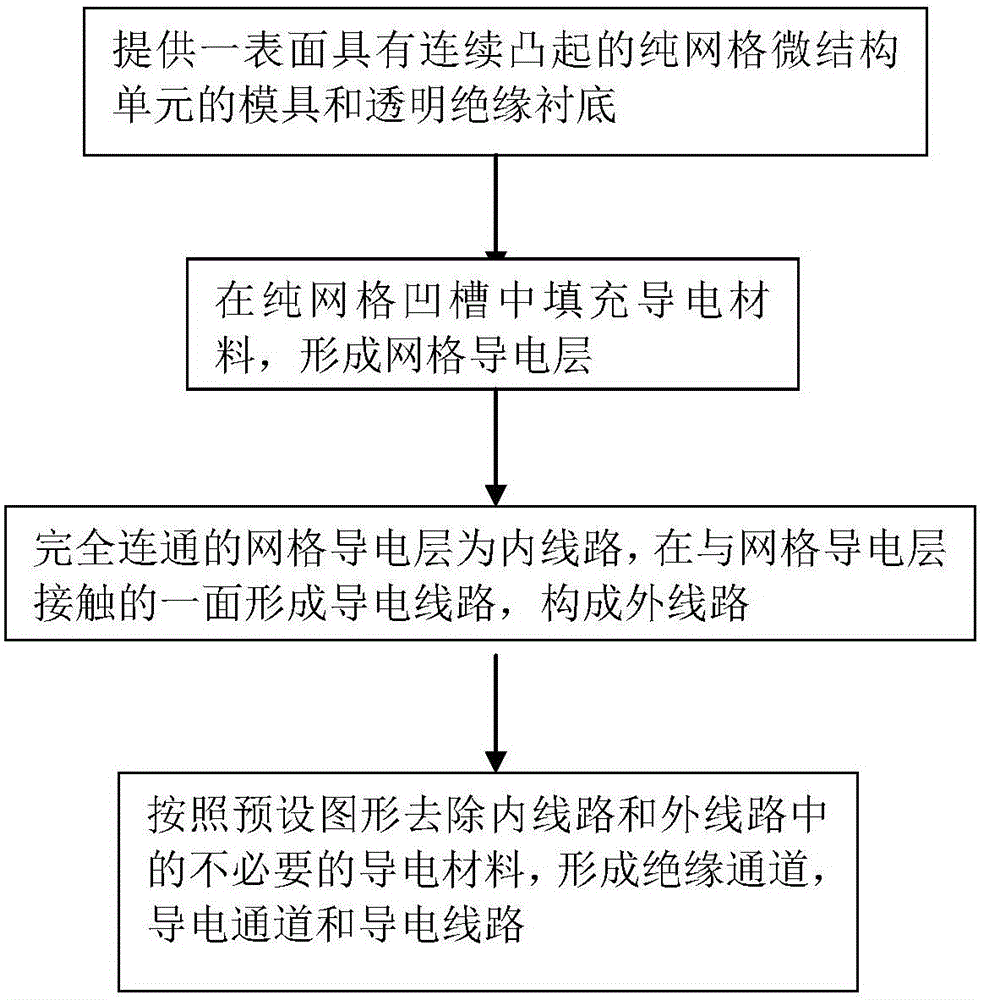

[0040] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

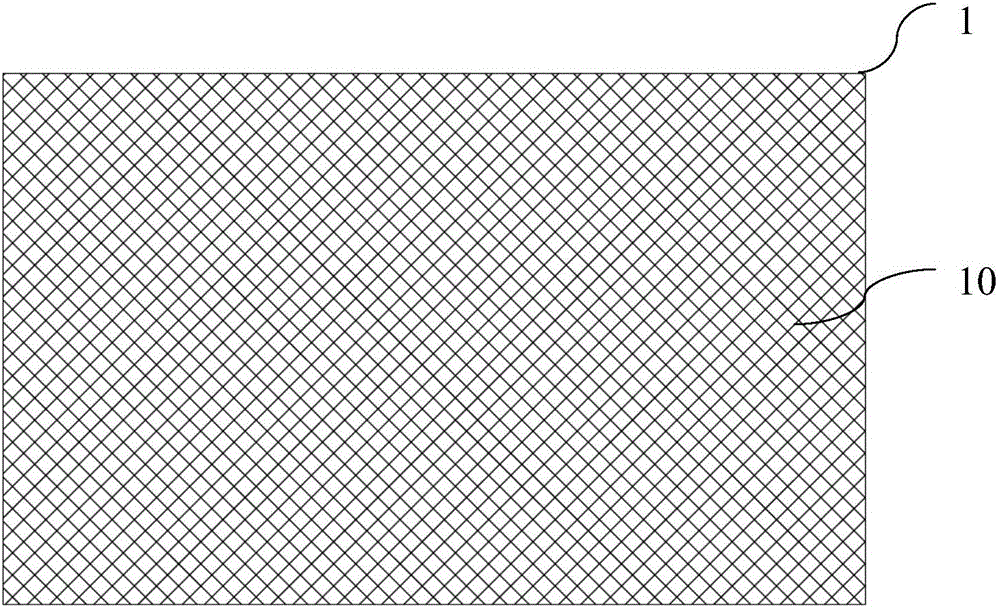

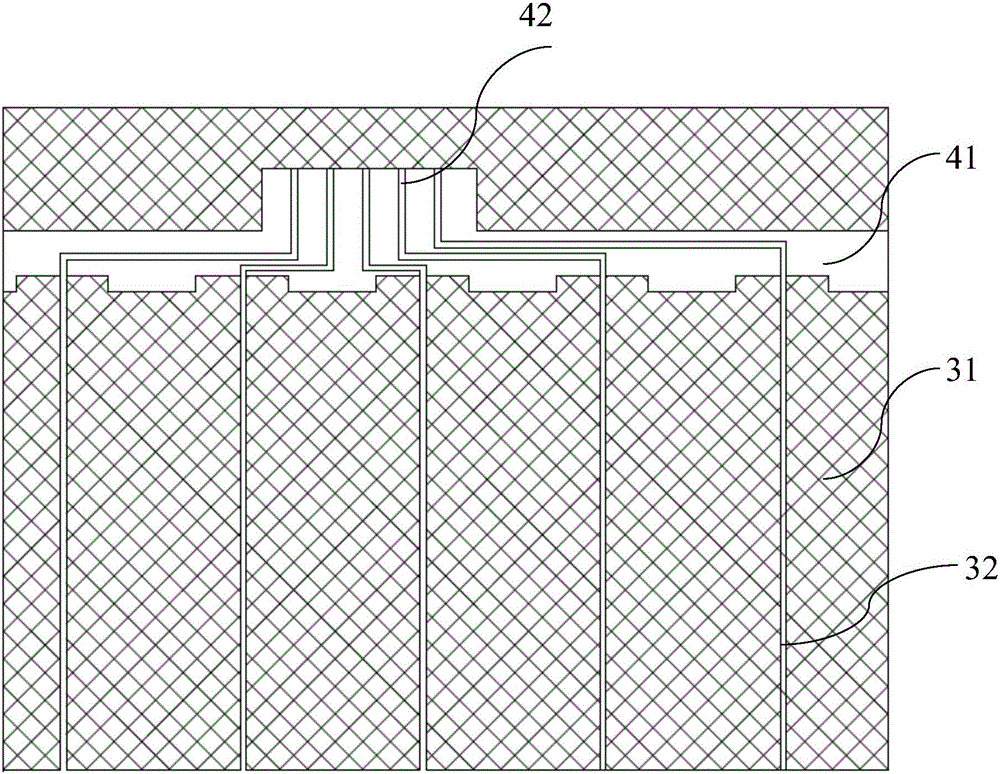

[0041] A transparent conductive film. The transparent conductive film is divided into a conductive area and a non-conductive area. The conductive area is composed of an inner line and an outer line. There are grid lines in the non-conductive area, and there is no conductive material in the groove of the grid line. In a preferred embodiment, the circuit channels in the conductive region are divided by laser or etching, and the division interval is preferably 20 microns. The grid of the conductive area can be in any shape, such as: square, rectangle, rhombus, diamond, pentagon, hexagon, random grid, etc. The routing method of the dividing line can be single or multiple straight lines, oblique lines, and is not limited by the shape of the channel. The grid line is a buried groove structure, which belongs to the metal grid structure.

[0042] r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com