Laminated plate theory-based optimization design method for composite bone fracture plate

A composite material, optimization design technology, applied in design optimization/simulation, calculation, electrical digital data processing, etc., can solve problems such as easy failure, poor fatigue resistance, and excessive difference between elastic modulus and bone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0104] In order to describe the present invention more specifically, the method for optimal design of the composite bone plate of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

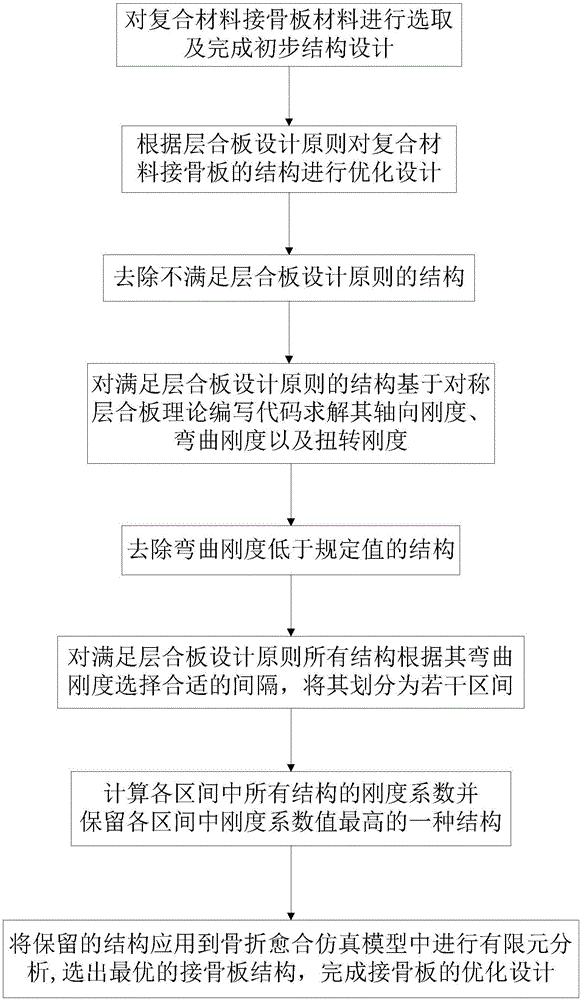

[0105] Such as figure 1 As shown, an optimal design method of composite bone plate based on laminate theory includes the following steps:

[0106] Step 1: Optimizing the structure of the composite material bone plate, the outer layer material of the composite material bone plate is carbon fiber and / or epoxy resin, and the inner layer material is flax fiber and / or epoxy resin;

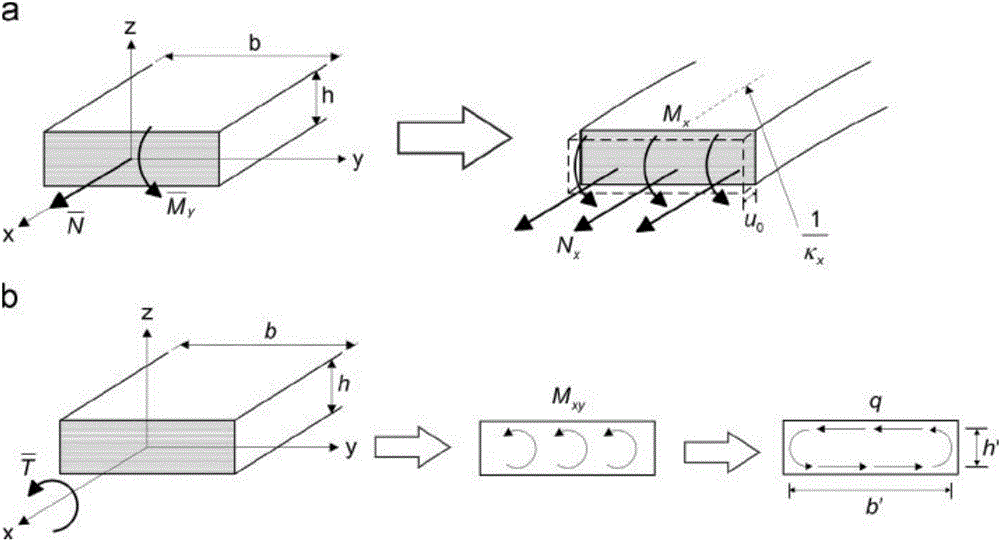

[0107] Step 2: The structural essence of the composite material bone plate is a laminated plate structure. The optimized design first reasonably designs the total thickness of the bone plate according to the actual fracture site of the human body, and then calculates the total number of layers of the laminated plate, carbon fiber and The quantity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com