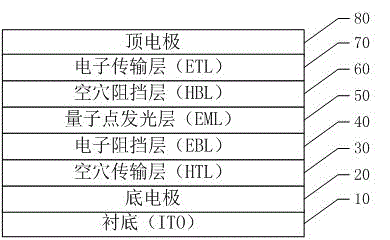

Quantum-dot Light-Emitting Diode (QLED) device based on p-i-n structure and fabrication method of QLED device

A p-i-n device technology, applied in the field of quantum dots, can solve the problems of poor stability, low luminous efficiency and short service life of quantum dot devices, and achieve the effects of reducing quenching, reducing cross-relaxation and improving current efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] In a QLED, glass substrate, 120nm ITO; HTL is F4-TCNQ:TFB=1:10, thickness is 25nm; EBL is TFB, EBL thickness is 15nm; i-EML is a quantum dot layer ( CdSe / ZnS) QDs / PMMA, the weight percentage of quantum dot material CdSe / ZnS and host material PMMA is 10:1, and the thickness is 40 nanometers; HBL is nano-zinc oxide, and the thickness is 10 nanometers; ETL is aluminum-doped zinc oxide, The doping concentration is 5wt%, the thickness is 20nm; the electrode is Al.

Embodiment 2

[0043] In a QLED, glass substrate, 120nm ITO; HTL is Cu:MoO 3 =10wt%, thickness is 25nm; EBL is MoO 3 , EBL thickness is 10nm; i-EML is the quantum dot layer (CdSe / ZnS) QDs / PMMA introduced into the intrinsic host material PMMA, the weight percentage of quantum dot material CdSe / ZnS and host material PMMA is 10:1, and the thickness is 40 nanometer; HBL is nano-zinc oxide with a thickness of 10 nanometers; ETL is lithium-doped zinc oxide with a doping concentration of 5% and a thickness of 20 nm; the electrode is Al.

Embodiment 3

[0045] In a QLED, glass substrate, 120nm ITO; HTL is F4-TCNQ:TFB = 1:10, thickness is 25nm; EBL is TFB, EBL thickness is 15nm; i-EML is the introduction of intrinsic matrix material SiO 2 Quantum dot layer of sol (CdSe / ZnS) QDs / SiO 2 , quantum dot material CdSe / ZnS and host material SiO 2 The weight percentage is 10:1, and the thickness is 40 nm; HBL is nano-zinc oxide, with a thickness of 10 nm; ETL is aluminum-doped zinc oxide, with a doping concentration of 5wt% and a thickness of 20 nm; the electrode is Al.

[0046] To sum up, the present invention provides a QLED device based on a p-i-n structure. On the one hand, the driving voltage of the QLED device is reduced by using a p-type material as a hole transport layer and an n-type material as an electron transport layer, thereby effectively reducing the Quenching of the luminescence of quantum dots by the Stark effect; on the other hand, the cross-relaxation between quantum dots can be reduced by introducing intrinsic hos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com