Method for preparing LaAlO3 powder by means of molten salt method

The technology of lanthanum aluminate and powder is applied in the field of preparation of lanthanum aluminate powder, which can solve the problems of low purity, uneven particle size distribution of lanthanum aluminate powder, and high synthesis temperature, and achieves high purity and environmental friendliness. Preparation method, effect of low synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

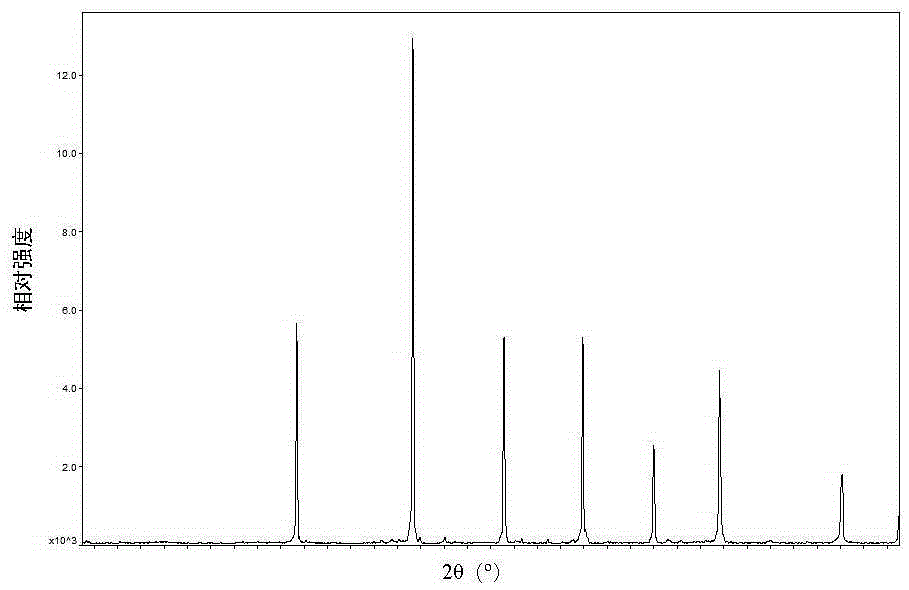

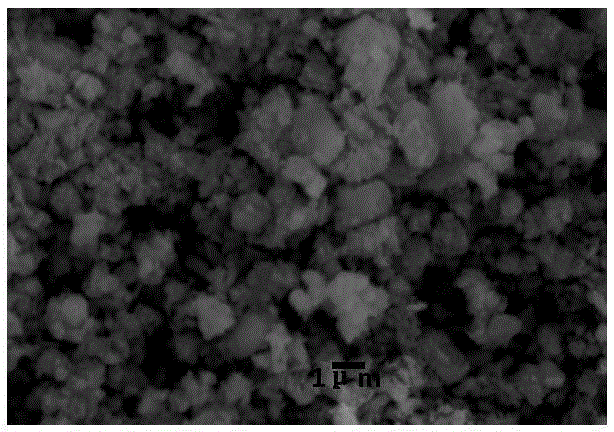

[0028] The particle size of the lanthanum aluminate powder obtained by the preparation method of the present invention is 0.1-3 μm, and the shape is cubic.

[0029] The purity of the lanthanum aluminate powder prepared by the invention is above 99%, even as high as 99.8%.

[0030] The lanthanum aluminate powder prepared in the example of the present invention has small particle size, uniform distribution, high purity, and can be mass-produced.

[0031]The characteristics of the present invention are: compared with the traditional solid-phase method, the example of the present invention uses molten salt as the reaction medium, which provides a liquid-phase reaction environment, and the reaction temperature is significantly reduced from 1000°C to 700-800°C; medium, avoiding the agglomeration between lanthanum aluminate powders; the molten salt used is soluble in deionized water, easy to collect lanthanum aluminate powder, and the molten salt can be recycled and used repeatedly, ...

Embodiment 1

[0034] Lanthanum oxide and aluminum oxide are used as initial raw materials, wherein the purity of lanthanum oxide is 99.8% (mass percentage) and the purity of aluminum oxide is 99.9% (mass percentage). The balance weighs 3.26g of lanthanum oxide, 1.02g of aluminum oxide, and 12.84g of sodium chloride and potassium chloride molten salt, and grinds for ten minutes with a mortar. Then put it into a resistance furnace and raise the temperature to 800°C at a rate of 5°C / min to react for 4 hours, and then lower the temperature with the furnace. Wash with 34ml of deionized water and suction-filter the obtained filter cake containing the reactant, and then wash with 34ml of deionized water and suction-filter the obtained filter cake, and repeat this five times. Until no white precipitate was detected by silver nitrate. Then the washed product was baked in an oven at 100°C for 4 hours to obtain 4.1 g of lanthanum aluminate powder with a purity of 99%.

Embodiment 2

[0036] Lanthanum oxide and aluminum oxide are used as initial raw materials, wherein the purity of lanthanum oxide is 99.8% (mass percentage) and the purity of aluminum oxide is 99.9% (mass percentage). Weigh 3.26g of lanthanum oxide, 1.02g of aluminum oxide, and 21.4g of molten salt of sodium chloride and potassium chloride on the balance, and grind for ten minutes with a mortar. Then put it into a resistance furnace and raise the temperature to 800° C. for 6 hours at a rate of 5° C. / min, and then cool down with the furnace. Wash with 51ml of deionized water and suction filter the obtained filter cake containing the reactant, and then wash with 51ml of deionized water and suction filter the obtained filter cake, and repeat this five times. Until no white precipitate was detected by silver nitrate. Then the washed product was baked in an oven at 100° C. for 4 hours to obtain 4.1 g of lanthanum aluminate powder with a purity of 99%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com