Graphene 3D printing material with high melt index

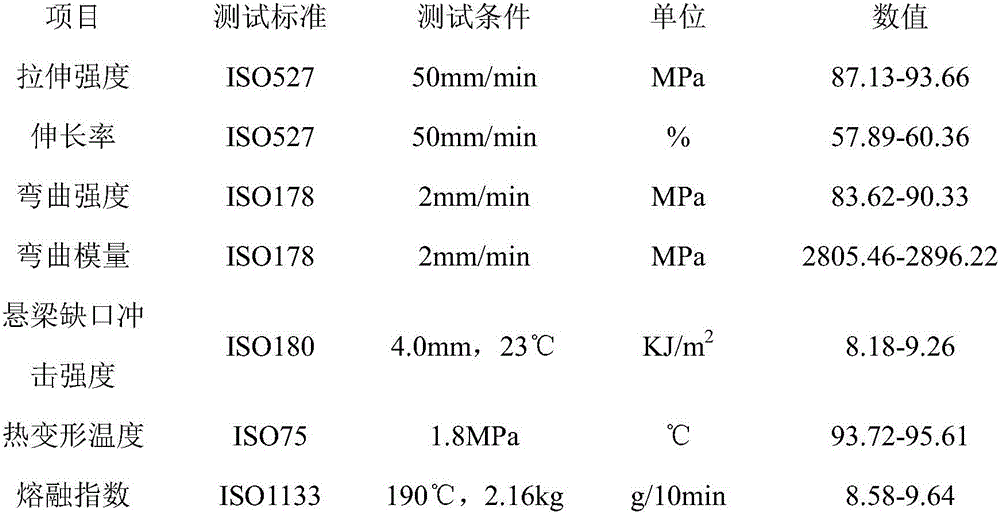

A high melt index, 3D printing technology, used in additive processing and other directions, can solve the problems of low thermal deformation temperature and melt index, tensile strength, bending strength, notch impact strength, etc., and achieve high thermal deformation temperature and melt index. , flexural strength and notched impact strength, the effect of a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0076] The preparation method of the described graphene 3D printing material with high melt index comprises the following steps:

[0077] S1: Purchase two-dimensional graphene raw materials on the market, and prepare primary graphene powder through special treatment;

[0078] S2: Use a hard plastic crusher to initially crush waste plastics, and then use an intermittent stirring plastic washing machine to thoroughly clean the crushed waste plastics to remove surface dirt. After natural drying and selection, selected plastics are obtained;

[0079] S3: Put the selected plastic prepared in step S2 in a nitrogen or dry ice low-temperature pulverizer, pulverize the plastic at a temperature of -90--110°C for 2-3 hours, and obtain 400-600 mesh plastic fine particles after sieving ;

[0080] S4: Add polylactic acid, sodium hexapolyphosphate, propylene glycol methyl ether acetate, and specific synthetic agents to the primary graphene powder obtained in step S1 and the fine plastic par...

Embodiment 1

[0093] A graphene 3D printing material with a high melt index, in parts by weight, comprising the following raw materials: 6.6 parts of graphene, 28 parts of waste plastics, 38 parts of polylactic acid, 20 parts of sodium hexapolyphosphate, propylene glycol methyl ether 24 parts of acetate, 16 parts of specific synthetic agent, 8 parts of starch synthetic agent;

[0094] The specific synthetic agent is in parts by weight, including the following raw materials: 18 parts of regulator, 15 parts of generating agent, 13 parts of coupling agent a, 14 parts of compatibilizer, 10 parts of plasticizer, 8 parts of antioxidant, polymer 7 parts of coagulant, 4 parts of terminator, 3 parts of stabilizer a;

[0095] The regulator is ACR;

[0096] The generating agent is an aerosol generating agent;

[0097] The coupling agent a is a silane coupling agent KH550;

[0098] Described compatibilizer is maleic anhydride graft compatibilizer;

[0099] Described plasticizer is two (2-ethylhexyl...

Embodiment 2

[0131] A graphene 3D printing material with a high melt index, in parts by weight, comprising the following raw materials: 5.4 parts of graphene, 25 parts of waste plastics, 35 parts of polylactic acid, 12 parts of sodium hexapolyphosphate, propylene glycol methyl ether 18 parts of acetate, 9 parts of specific synthetic agent, 5 parts of starch synthetic agent;

[0132] The specific synthetic agent is in parts by weight, including the following raw materials: 15 parts of regulator, 12 parts of generating agent, 10 parts of coupling agent a, 12 parts of compatibilizer, 9 parts of plasticizer, 6 parts of antioxidant, polymer 5 parts of coagulant, 3 parts of terminator, 2 parts of stabilizer a;

[0133] The regulator is ACR;

[0134] The generating agent is an aerosol generating agent;

[0135] The coupling agent a is a silane coupling agent KH550;

[0136] Described compatibilizer is maleic anhydride graft compatibilizer;

[0137] Described plasticizer is two (2-ethylhexyl) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com