Preparing method of graphene modified waterborne polyurethane composite material

A water-based polyurethane and graphene modification technology, which is applied in graphene, conductive coatings, nano-carbon, etc., can solve the problems of poor dispersion, affecting the compatibility and dispersion of graphene sheets, etc., and achieves low cost and excellent preparation method The effect of simplicity and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

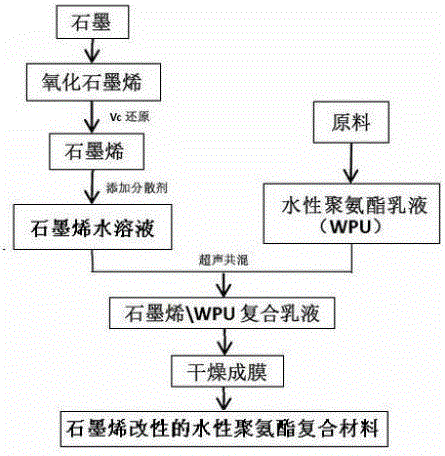

[0042] see figure 1 . A preparation method of graphene-modified water-based polyurethane composite material, comprising the following steps:

[0043] (1) Preparation of prepolymer

[0044] Add 6.97g of toluene-2,4-diisocyanate (TDI) into a four-necked flask, blow nitrogen into it, and slowly add 18g of polypropylene glycol (PPG, with a number average molecular weight of 2000) dropwise (the polypropylene glycol and toluene-2,4 - The molar ratio of diisocyanate is 0.9-1.5:4), stirring and reacting at 60°C for 2 hours to obtain a prepolymer.

[0045] (2) Preparation of water-based polyurethane emulsion

[0046] ① Add 0.67g of dimethylolpropionic acid (DMPA) to the prepolymer obtained in step (1), and react at 80°C for 1 hour.

[0047] ②Reduce the temperature to 40°C, add acetone to reduce the viscosity, and then add 0.84g of diethylene glycol to react for 1 hour.

[0048] ③Reduce the temperature to 10°C, add 0.51g of triethylamine (TEA), and continue the reaction for 40 minu...

Embodiment 2

[0067] A preparation method of graphene-modified water-based polyurethane composite material, comprising the following steps:

[0068] (1) Preparation of prepolymer

[0069] Add 6.96g of toluene-2,4-diisocyanate (TDI) into a four-necked flask, blow in nitrogen, slowly add 30g of polypropylene glycol (PPG) dropwise, and stir and react at 70°C for 2 hours to obtain a prepolymer.

[0070] (2) Preparation of water-based polyurethane emulsion

[0071] ① Add 0.94g dimethylolpropionic acid (DMPA) to the prepolymer obtained in step (1), and react at 80°C for 2 hours.

[0072] ②Reduce the temperature to 40°C, add acetone to reduce the viscosity, and then add 1.06g of diethylene glycol to react for 1 hour.

[0073] ③Reduce the temperature to 10°C, add 0.81g of triethylamine (TEA), and continue the reaction for 1 hour.

[0074] ④ Add the reaction product to 93g of deionized water, stir, shear and emulsify for 1 hour in an ice-water bath to obtain a water-based polyurethane emulsion wi...

Embodiment 3

[0091] A preparation method of graphene-modified water-based polyurethane composite material, comprising the following steps:

[0092] (1) Preparation of prepolymer

[0093] Add 7.18g of toluene-2,4-diisocyanate (TDI) into a four-necked flask, blow nitrogen gas, slowly add 20g of polypropylene glycol (PPG) dropwise, and stir and react at 70°C for 2 hours to obtain a prepolymer.

[0094] (2) Preparation of water-based polyurethane emulsion

[0095] ①Add 1g of dimethylolpropionic acid (DMPA) to the prepolymer obtained in step (1), and react at 80°C for 1 hour.

[0096] ②Reduce the temperature to 40°C, add acetone to reduce the viscosity, and then add 1.06g of diethylene glycol to react for 1 hour.

[0097] ③Reduce the temperature to 10°C, add 1g of triethylamine (TEA), and continue the reaction for 1 hour.

[0098] ④Add the reaction product to 70g of deionized water, stir, shear and emulsify for 1 hour in an ice-water bath to obtain a water-based polyurethane emulsion with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com