Polymer gel for well killing and preparing method and application of polymer gel

A technology of polymer and well killing, which is applied in drilling compositions, chemical instruments and methods, earthwork drilling and production, etc. It can solve the problems of difficult to meet formation pressure requirements, low compressive strength, and high gel cost. Achieve excellent gel breaking performance, improve compressive strength and compression performance, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

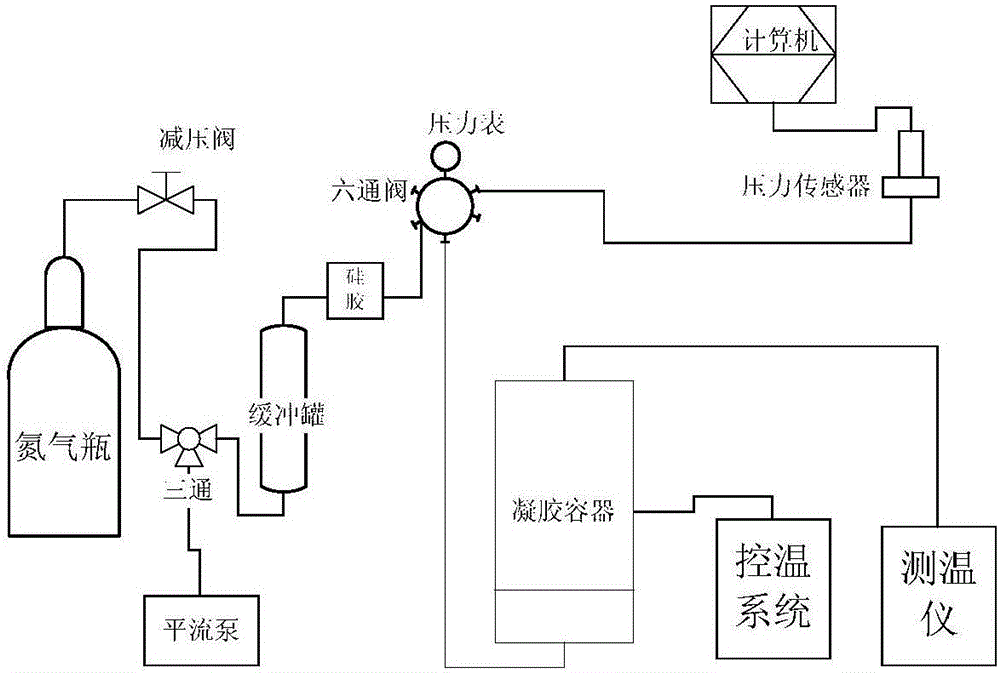

Method used

Image

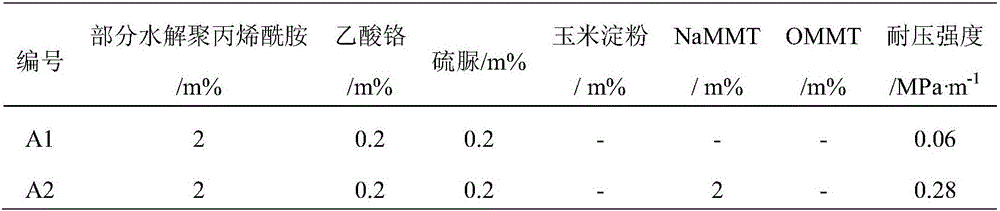

Examples

Embodiment 1

[0038] Use a balance to weigh an appropriate amount of tap water and add it to the beaker. Place the beaker under the stirrer, and the bottom of the stirring rod is about 1 cm from the bottom of the beaker. Turn on the switch of the DW-3 digital display electric agitator, adjust the stirring speed to about 400r / min, make the water form a vortex, then add a certain amount of structural enhancer according to the formula, use an ultrasonic oscillator to disperse for 30min, and a high-speed stirring mixer at 600r / min stirring for 30min. Then use an analytical balance to weigh thiourea and partially hydrolyzed polyacrylamide and add them to the vortex quickly and evenly. Continue to stir until the polymer is completely dispersed (generally take 4h of stirring). Stop stirring, and pour it into a clean reagent bottle after standing for 24 hours. After the polymer base liquid is left for 24 hours, weigh a certain amount of polymer base liquid in a clean beaker, turn on the stirrin...

Embodiment 2

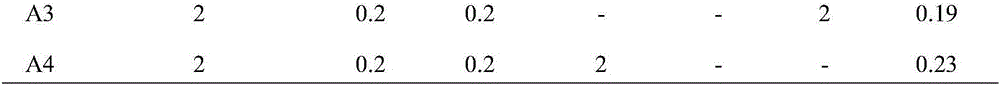

[0044] The preparation method is the same as that in Example 1; the difference is that in the formulation of the well killing polymer gel, the structural enhancer is sodium-based montmorillonite, and its content is respectively 1%, 3%, 5%, and 7%. Table 2 and Table 3 respectively show the compressive strength and compressive performance data of polymer gels for killing wells with different Na-montmorillonite contents.

[0045] Table 2 The compressive strength data of polymer gels with different montmorillonite contents

[0046]

[0047] As can be seen from Table 2, adding Na-montmorillonite can significantly improve the compressive strength of the polymer gel, and the compressive strength increases with the increase of montmorillonite content; when the addition of Na-montmorillonite is 7% , the compressive strength of the composite gel is the highest, up to 0.54MPa m -1 .

[0048] Table 3 The polymer gel compression test data of different montmorillonite content

[0049] ...

Embodiment 3

[0052] The preparation method is the same as that in Example 1; the difference is that in the formulation of the polymer gel for well killing, the structural enhancer is corn starch, and its content is respectively 1%, 3%, 5%, and 7%. Table 4 shows the compressive strength of well kill polymer gels with different cornstarch contents.

[0053] Table 4 Effect of cornstarch dosage on polymer gel compressive strength

[0054]

[0055] It can be seen from Table 4 that when the amount of corn starch is 5%, the compressive strength of the polymer gel is up to 0.40MPa·m -1 .

[0056] The gelation time of the polymer gel of the present invention is about 1.5 hours, and the formed gel has good thermal stability within 30 days at 70°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com