Process for producing high-softening-point gilsonite from coal tar heavy oil through vacuum deep extraction

A technology with high softening point and hard pitch, applied in the direction of tar processing by distillation, which can solve the problems of high viscosity and difficulty in meeting process requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

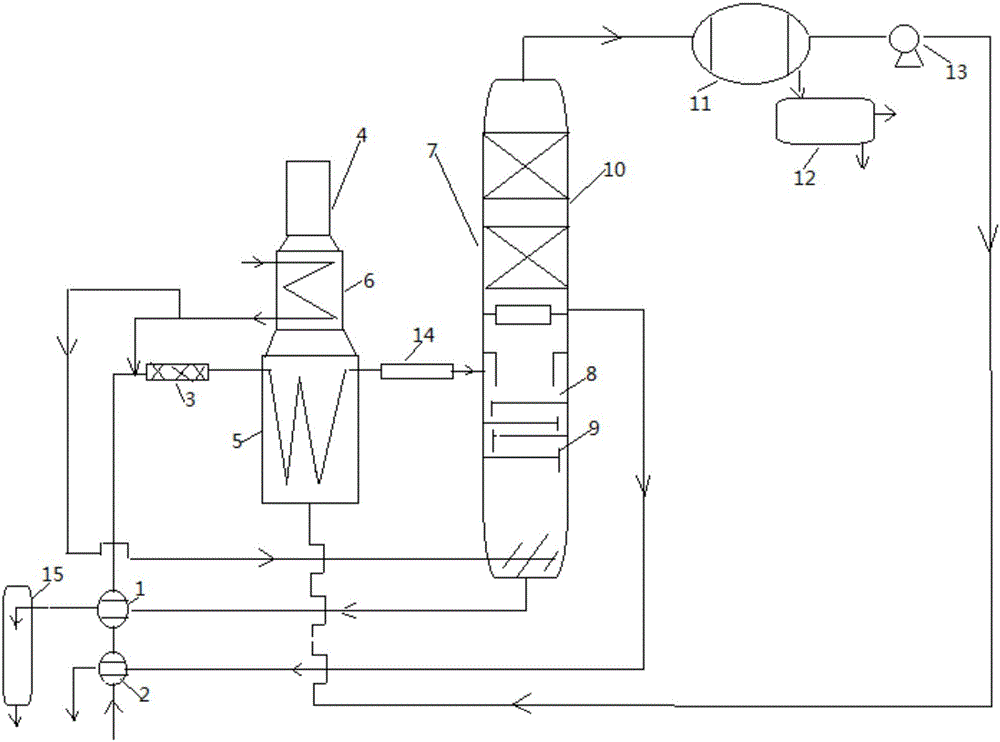

[0019] Example 1, the heavy coal tar oil at 80°C is exchanged with vacuum wax oil and vacuum residue oil to 260°C respectively through vacuum residue heat exchanger (1) and vacuum wax oil heat exchanger (2) , and then mixed with the injected 5%, 280°C high superheated water vapor through the static mixer (3), the mixed oil vapor enters the decompression heating furnace (4) radiant section (5) and is heated to 420°C, and is decompressed The oil line (14) enters the flash section (8) of the vacuum tower (7) at high speed, and the vacuum residue oil is separated from the wax oil gas and water vapor by flash evaporation; the vacuum residue oil is stripped through the stripping section (9) tray After separating the entrained wax oil and gas, it flows to the bottom of the vacuum tower (7), and the bottom of the vacuum tower (7) maintains a high liquid level of 4 meters, and the steam injection distributor at the bottom evenly injects 0.6% superheated steam at 280°C , carry out high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com