Temperature control device for COREX furnace gas and use method thereof

A technology of temperature control device and furnace top gas, which is applied in furnaces, fluidized bed furnaces, furnace types, etc., can solve the problems of untimely temperature control, loss of dust removal function, damage to cloth bags, etc., and achieves fast adjustment response and can be implemented Strong performance and stable system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

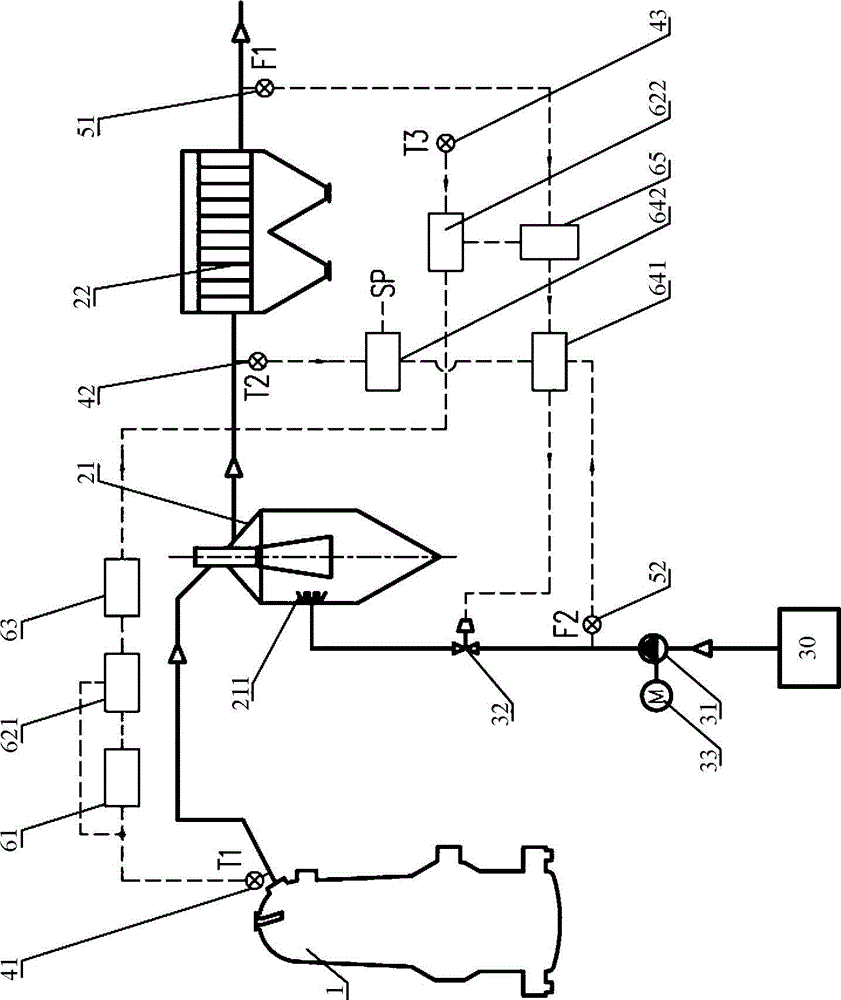

[0023] A temperature control device for COREX furnace top gas, including COREX shaft furnace 1, gravity dust collector 21, dry bag filter 22, temperature control device and computing device, such as figure 1 As shown, the specific structure is:

[0024] The gas outlet at the top of the COREX shaft furnace 1 is connected to the gravity dust collector 21 and the dry bag filter 22 in sequence through the gas pipeline, and the gas output from the gas outlet of the dry bag filter 22 is subjected to subsequent treatment (such as TRT, etc., TRT is Blast Furnace Top Gas Recovery Turbine Unit, which means blast furnace gas residual pressure turbine power generation device, is a by-product of blast furnace smelting, using the potential energy and heat energy of blast furnace top gas to make the gas work through a turbo expander to convert the potential energy of blast furnace top gas and thermal energy into mechanical energy, and then convert mechanical energy into electrical energy) an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com