Functional patch and preparation method and applications thereof

A functional, patch technology, applied in coating, medical science, filament/wire forming, etc., to achieve good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

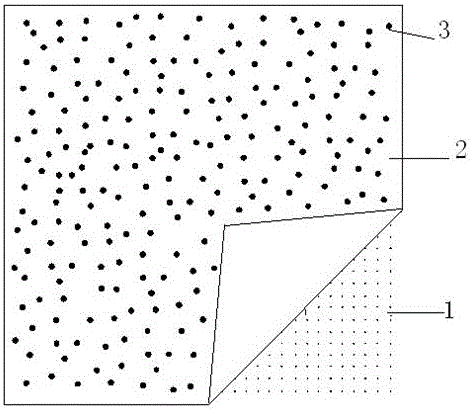

[0035] Example 1 PP / PLA / moxifloxacin functional patch

[0036] 1. Dissolve 2.01 g of polylactic acid (PLA) in 20.10 g of dichloromethane and stir until uniform to obtain a polymer solution, then add 0.10 g of moxifloxacin into the polymer solution, and stir until uniform to obtain a mixed solution.

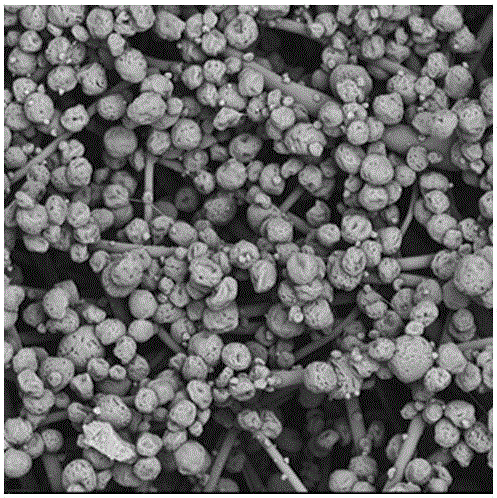

[0037] 2. Take 5mL of the mixed solution prepared in step 1, put it into a container with a spinneret, set up an electrospinning device with an electrostatic voltage of 25kV, and collect it with a flat-plate collecting device with a PP mesh. The flat-plate and -0.5 The kV voltage is connected, the distance between the spinneret and the spinning device is 20cm, the ambient temperature is controlled at 25°C, and the relative humidity of the environment is 57.5%, and the fiber film is obtained by spinning.

[0038] 3. Dissolve 0.45 g of polylactic acid (PLA) in 9.00 g of dichloromethane and stir until uniform to obtain a polymer solution, then add 0.045 g of moxifloxacin to the polym...

Embodiment 2

[0041] Example 2 PP / PLA / ciprofloxacin functional patch

[0042] 1. Dissolve 1.95g of polylactic acid (PLA) in 9.75g of dichloromethane and stir until uniform to obtain a polymer solution, then add 0.098g of ciprofloxacin into the polymer solution, and stir until uniform to obtain a mixed solution.

[0043]2. Take 5mL of the mixed solution prepared in step 1, put it into a container with a spinneret, set up an electrospinning device with an electrostatic voltage of 10kV, and collect it with a flat-plate collecting device with a PP mesh. The flat-plate and -20.0 The kV voltage is connected, the distance between the spinneret and the spinning device is 40cm, the ambient temperature is controlled at 10°C, and the relative humidity of the environment is 25%, and the fiber film is obtained by spinning.

[0044] 3. Dissolve 0.65 polylactic acid (PLA) in 6.50 g of dichloromethane and stir until uniform to obtain a polymer solution, then add 0.13 g of ciprofloxacin into the polymer sol...

Embodiment 3

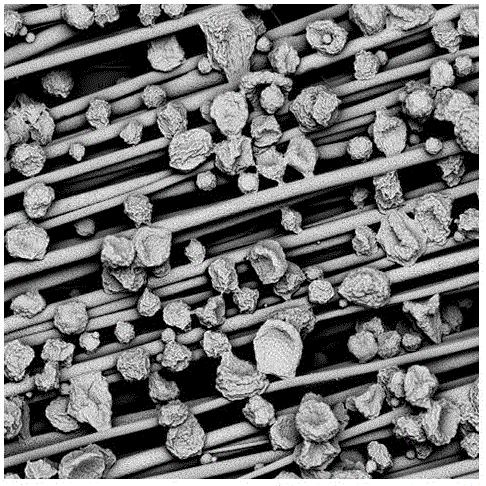

[0047] Example 3 PP / PLA aspirin functional patch

[0048] 1. Dissolve 0.16g of polylactic acid (PLA) in 16g of dichloromethane and stir until uniform to obtain a polymer solution, then add 0.24g of aspirin into the polymer solution, stir until uniform to obtain a mixed solution.

[0049] 2. Take 5mL of the mixed solution prepared in step 1, put it into a container with a spinneret, set up an electrospinning device with an electrostatic voltage of 10kV, and collect it with a point-to-point wire collection device with a PP mesh. Metal point electrodes and -0.5kV voltage connected, 5cm away from the drum, the drum speed 1525r / min, the distance between the spinneret and the drum is 3cm, the ambient temperature is controlled at 40°C, the relative humidity of the environment is 90%, and the fiber film is obtained by spinning.

[0050] 3. Dissolve 0.25 g of polylactic acid (PLA) in 3.57 g of dichloromethane and stir until uniform to obtain a polymer solution, then add 0.0036 g of asp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Bursting strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com