Preparation method of intelligent corrosion inhibition microcapsule

A technology of microcapsules and corrosion inhibition, applied in the directions of microcapsule preparation, microsphere preparation, coating, etc., can solve the problems of failure to achieve corrosion inhibition, release and leakage, etc., to avoid release and leakage, and the method is simple and feasible. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

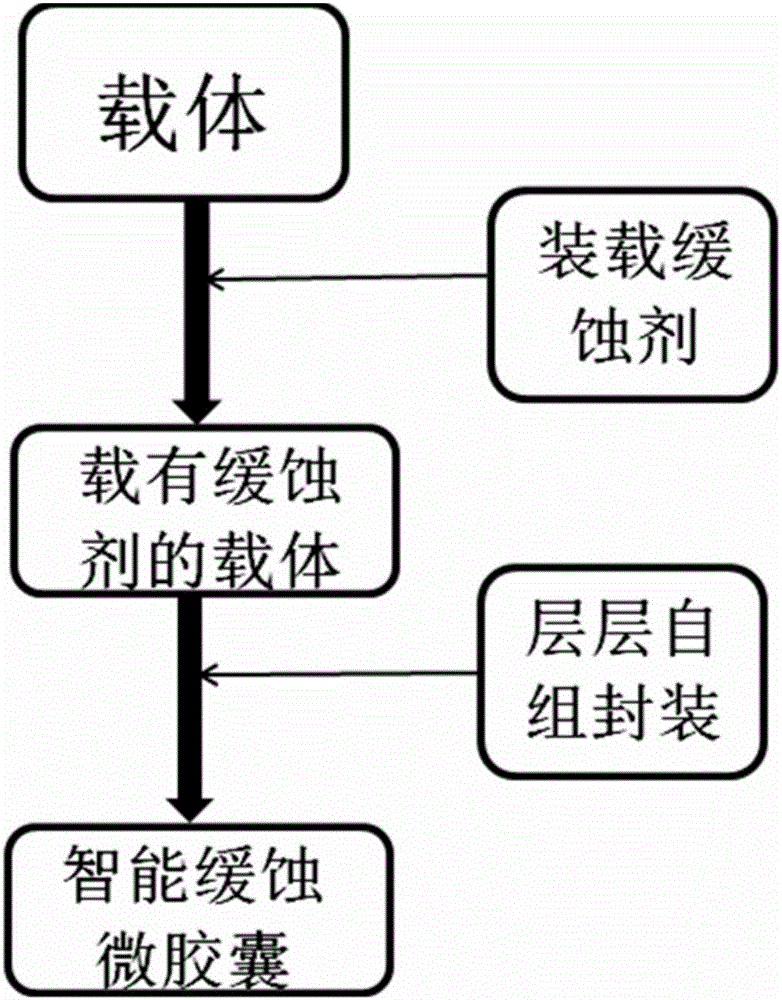

Method used

Image

Examples

Embodiment 1

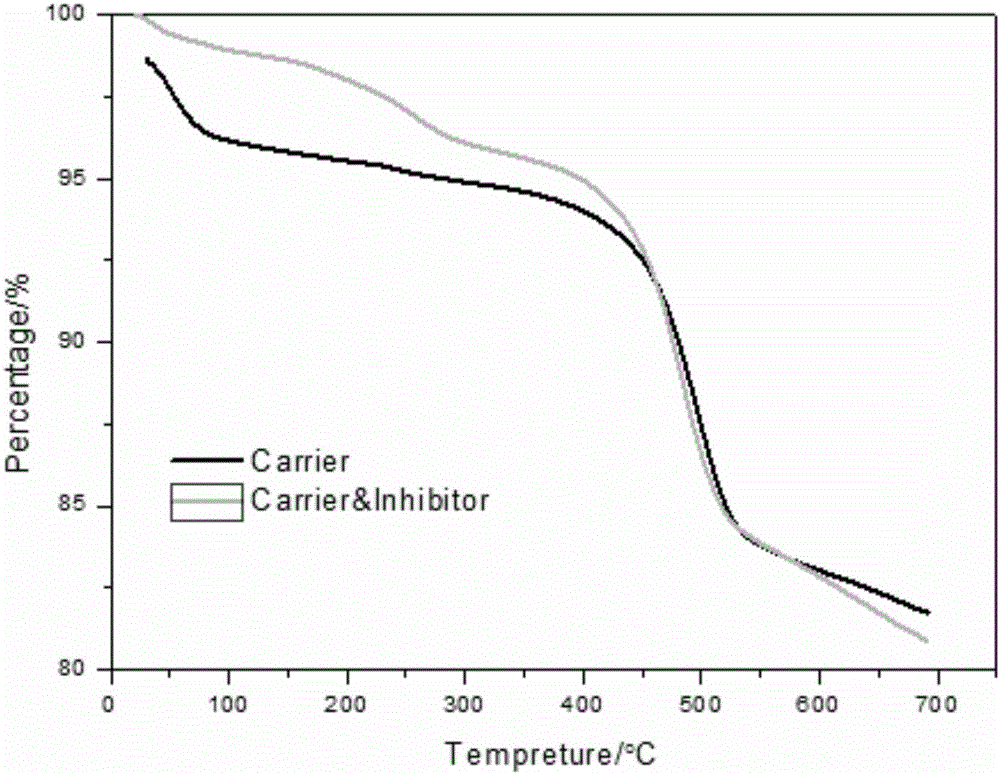

[0019] (1) 2-Mercaptobenzothiazole is used as the corrosion inhibitor to be loaded. Mix the corrosion inhibitor solution with the natural halloysite nanotube carrier at a ratio of 125:1, and carry out vacuum loading with ultrasonication for 10 minutes. The vacuum loading pressure is -0.1 MPa, the loading cycle is 4 and each loading cycle includes 30min of vacuum loading and 5min of normal pressure stirring treatment. The loaded sample is washed with ethanol solution, which is prepared by mixing absolute ethanol and distilled water in a ratio of 1:4, and the number of cleanings is 3. After cleaning, the sample can be centrifuged and dried.

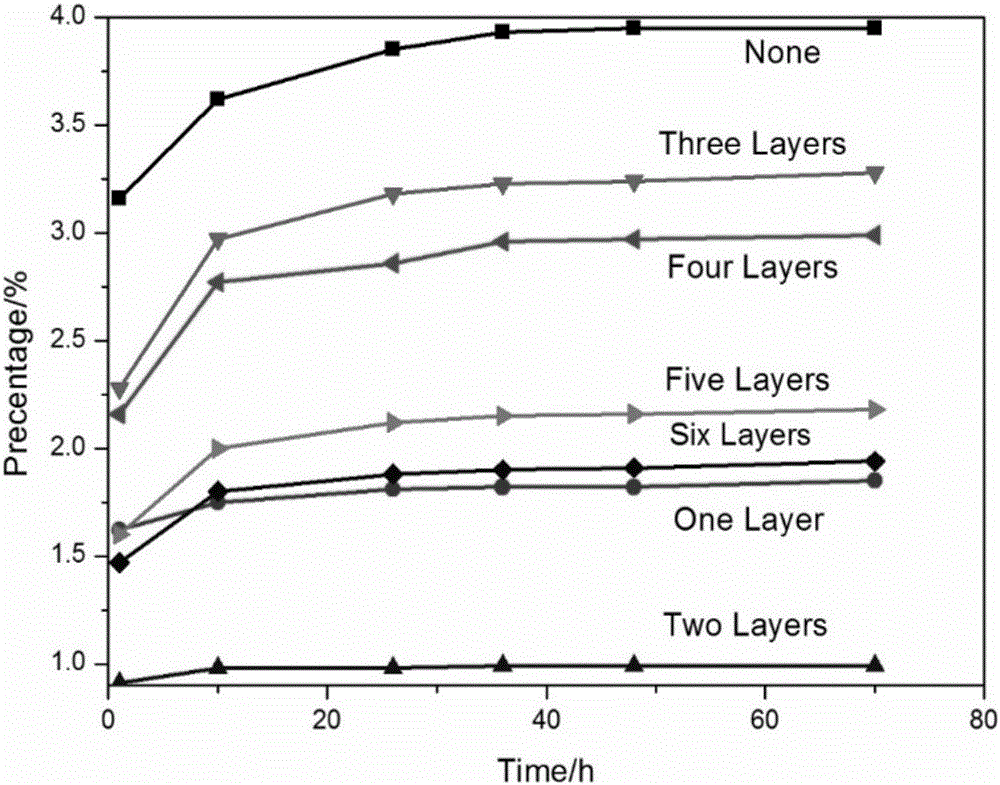

[0020] (2) configure polydiene dimethyl ammonium chloride concentration to be 4mgmL -1 Aqueous solution and sodium polystyrene sulfonate in 3.5wt% NaCl 4mgmL -1 solution.

[0021] (3) Mix the loaded microcontainer carrier with the polydiene dimethyl ammonium chloride solution, then stir and ultrasonically treat, seal for 5 minutes, and ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com