Method for preparing high-dispersion loaded-type noble-metal powder catalyst

A precious metal, supported technology, used in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc. Agglomeration and other problems, to achieve the effect of easy control of process operation, high catalytic activity and selectivity, and high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

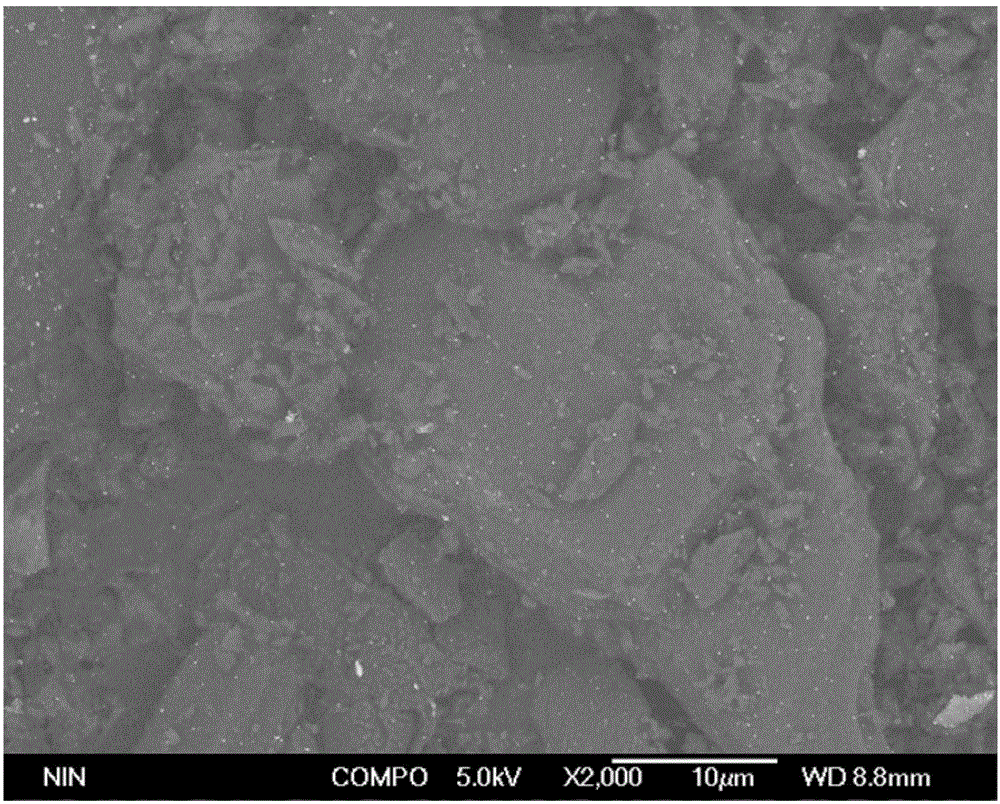

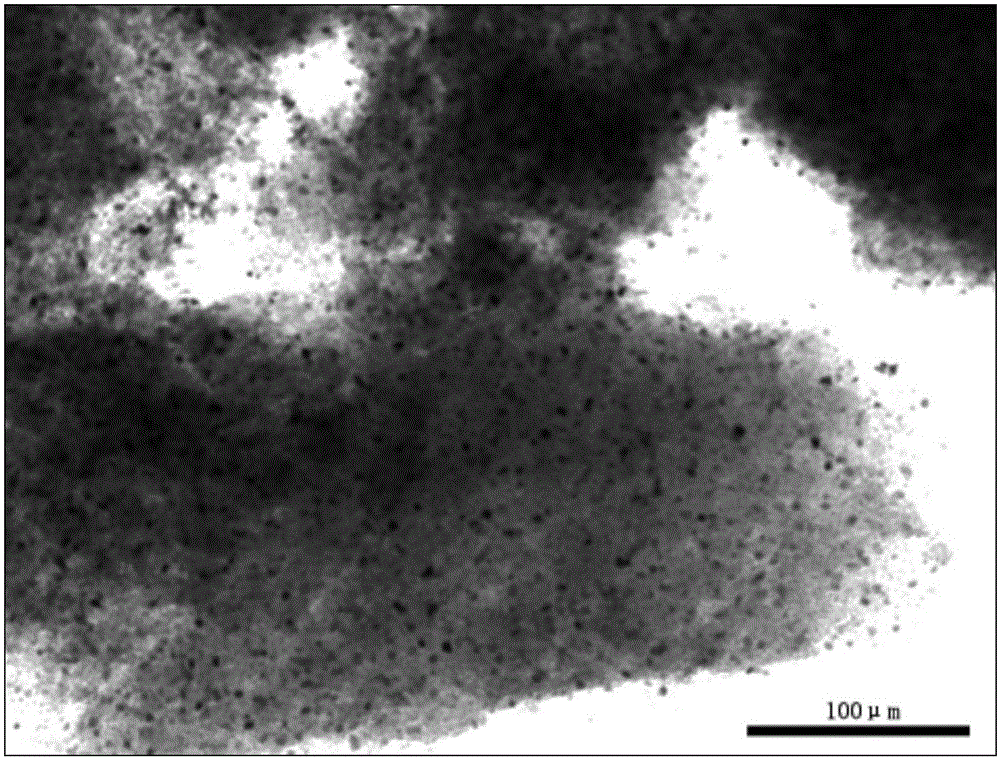

Image

Examples

Embodiment 1

[0029] The method for preparing a highly dispersed loaded noble metal powder catalyst in this embodiment comprises the following steps:

[0030] Step 1, uniformly mixing the powdery alumina carrier and deionized water to form a suspension; dissolving palladium chloride in deionized water to form an aqueous phase solution;

[0031] The mass percentage of the powdered alumina carrier in the suspension is 30%, the mass concentration of the noble metal precursor in the aqueous solution is 0.05g / mL; the mass content of palladium in the palladium chloride is the 1% of the above-mentioned powdered alumina carrier mass;

[0032] Step 2, adding the suspension described in step 1 into the stirred tank type slurry reactor, starting stirring, and adding sodium carbonate to adjust the pH value of the suspension to 9.2;

[0033] Step 3, after the aqueous phase solution described in step 1 is atomized by a high-pressure atomizer, the atomized particles with a particle diameter of 3um are sp...

Embodiment 2

[0036] The method for preparing a highly dispersed supported noble metal powder catalyst in this embodiment comprises the following steps:

[0037] Step 1, uniformly mixing the powdery titanium dioxide carrier and deionized water to form a suspension; dissolving potassium chloroplatinate in deionized water to form an aqueous phase solution;

[0038] The mass percentage of powdered titanium dioxide carrier in the suspension is 40%, and the mass concentration of potassium chloroplatinate in the aqueous solution is 0.03g / mL; the mass content of platinum in the potassium chloroplatinate is 5% of the mass of the powdery titanium dioxide carrier;

[0039]Step 2, adding the suspension described in step 1 into the stirred tank type slurry reactor, starting stirring, and adding potassium carbonate to adjust the pH value of the suspension to 8.5;

[0040] Step 3. After atomizing the aqueous phase solution described in step 1 through a high-pressure spray nozzle, spray the atomized part...

Embodiment 3

[0043] The method for preparing a highly dispersed loaded noble metal powder catalyst in this embodiment comprises the following steps:

[0044] Step 1, uniformly mixing the powdered activated carbon carrier with deionized water to form a suspension; dissolving rhodium trichloride in deionized water to form an aqueous phase solution;

[0045] The mass percent composition of powdered activated carbon carrier in the described suspension is 15%, and the mass concentration of rhodium trichloride in the described aqueous phase solution is 0.15g / mL; The mass content of rhodium in the described rhodium trichloride is 10% of the mass of the powdered activated carbon carrier;

[0046] Step 2, adding the suspension described in step 1 into the stirred tank type slurry reactor, starting stirring, and adding potassium carbonate to adjust the pH value of the suspension to 9.8;

[0047] Step 3, after the aqueous phase solution described in step 1 is atomized by an ultrasonic atomizer, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com