A simple method for synthesizing bismuth oxyiodide quantum dot photocatalyst

A technology of bismuth oxyiodide and quantum dots, which is applied in the field of simple synthesis of bismuth oxyiodide quantum dot photocatalysts, can solve the problems of low macroscopic efficiency, low utilization rate of visible light, and the simple preparation technology of BiOI quantum dot structure has not been reported yet, and achieves high efficiency. Photocatalytic degradation of organic pollutants, large application potential, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Mix 34mL n-hexane, 9mL triton and 7mL n-hexanol, and stir magnetically for 30min at a speed of 800r / min;

[0026] 2. Add 20 μL of deionized water to the mixed oil phase formed in step 1, and continue stirring at the above stirring speed for 30 minutes;

[0027] 3, 1mmol bismuth nitrate (molecular formula Bi(NO 3 ) 3 ·5H 2 (2) and 1mmol potassium iodide (molecular formula KI) are dissolved in 10mL ethylene glycol respectively, obtain respectively the ethylene glycol solution of the bismuth nitrate of 100mmol / L and the ethylene glycol solution of potassium iodide;

[0028] 4. Under the stirring condition of 800r / min, drop the solution in step 3 into the oil-water mixing system in step 2 at a rate of 1 drop / s and continue stirring for 2h;

[0029] 5. After the reaction, centrifuge at 32000r / min for 20min, freeze the bottom product at -76°C, and dry at 50°C under 2Pa vacuum for about 6h to obtain the final sample.

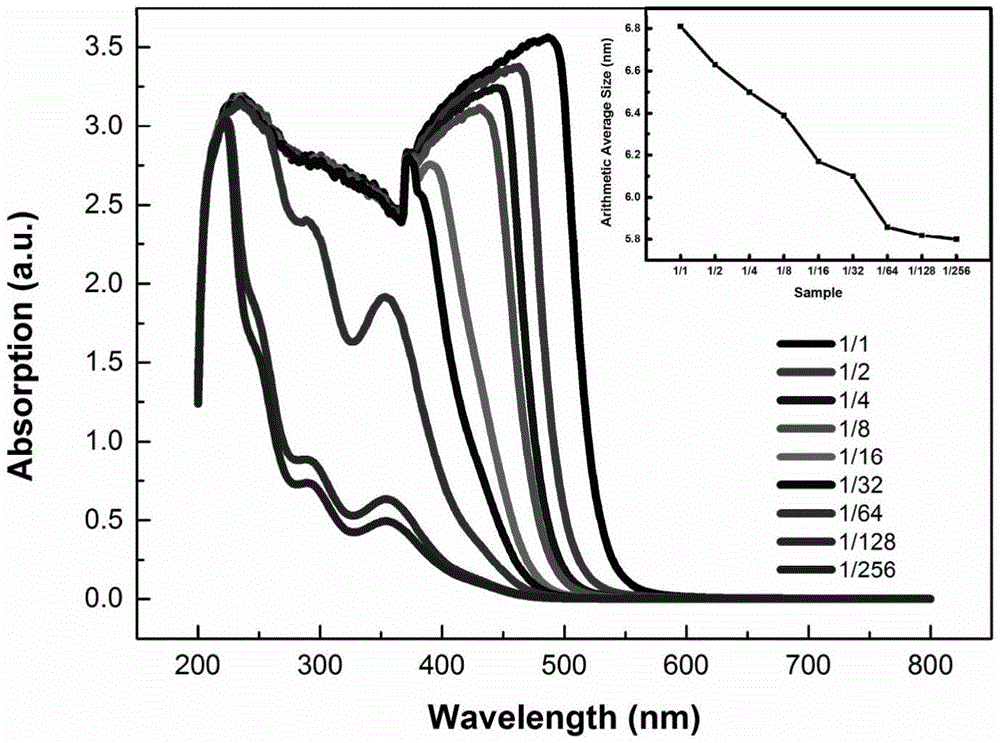

[0030] Then the obtained samples were characterized...

Embodiment 2

[0035] 1. Mix 34mL n-hexane, 9mL triton, and 7mL n-hexanol, and stir magnetically at 1000r / min for 30min;

[0036] 2. Add 500 μL deionized water to the mixed oil phase formed in step 1, and continue stirring for 30 minutes;

[0037] 3. Mix 1mmolBi(NO 3 ) 3 ·5H 2 O and 1mmolKI are dissolved in 10mL ethylene glycol respectively, and obtaining concentration is the ethylene glycol solution of the bismuth nitrate of 100mmol / L and the ethylene glycol solution of potassium iodide respectively;

[0038] 4. Under the stirring condition of 1000r / min, drop the solution in step 3 into the oil-water mixing system in step 2 at a rate of 1 drop / s and continue stirring for 2h;

[0039] 5. After the reaction, centrifuge at 30,000r / min for 15min, freeze the bottom product at -76°C, and dry at 50°C for about 6h under 2Pa vacuum to obtain the final sample (see Figure 5A ).

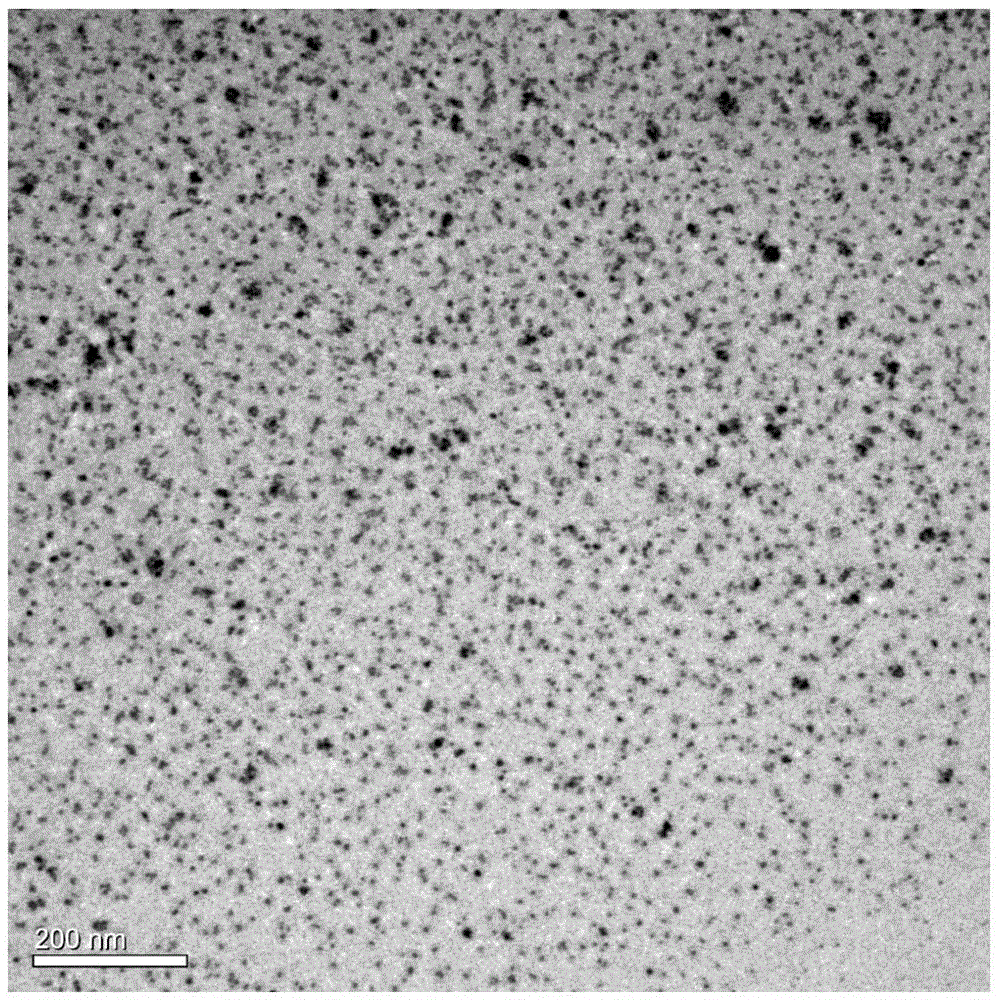

[0040] Depend on Figure 5A It can be seen that the obtained samples have two typical morphologies through scanning el...

Embodiment 3

[0042] 1. Mix 34mL n-hexane, 9mL triton, and 7mL n-hexanol, and stir magnetically at 900r / min for 30min;

[0043] 2. Add 250 μL deionized water to the mixed oil phase formed in step 1, and continue stirring for 30 minutes;

[0044] 3. Mix 1mmolBi(NO 3 ) 3 ·5H 2 O and 1mmolKI are dissolved in 10mL ethylene glycol respectively, and obtaining concentration is the ethylene glycol solution of the bismuth nitrate of 100mmol / L and the ethylene glycol solution of potassium iodide respectively;

[0045] 4. Under the stirring condition of 900r / min, drop the solution in step 3 into the oil-water mixing system in step 2 at a rate of 1 drop / s and continue stirring for 2h;

[0046] 5. After the reaction, centrifuge at 32000r / min for 20min, freeze the bottom product at -76°C, and dry at 50°C for about 6h under 2Pa vacuum to obtain the final sample (see Figure 5B ).

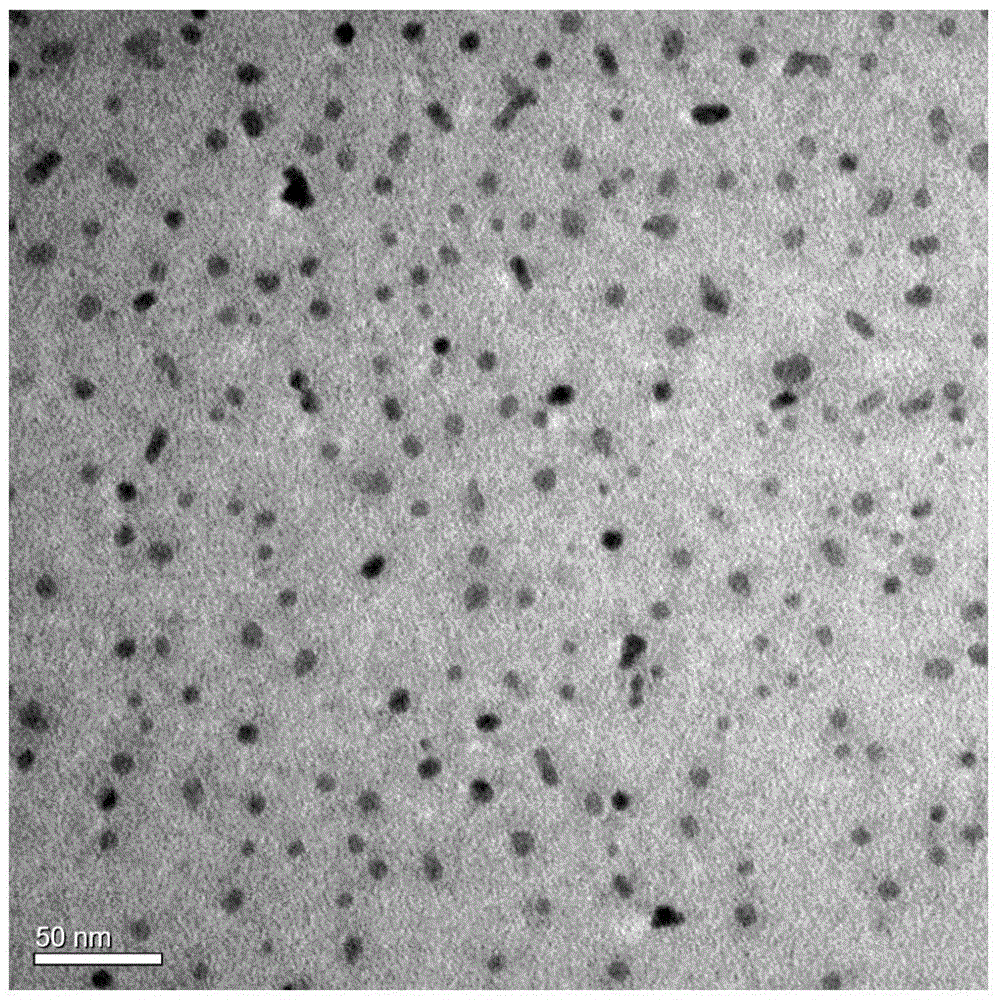

[0047] Depend on Figure 5B It can be seen that the obtained samples are particles with a size of 30-50 nm and no quant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com