A process for preparing cellulose nanocrystal dispersion based on controllable dissolution

A process method, cellulose technology, applied in the field of preparation of cellulose nanocrystal dispersion liquid based on controllable dissolution, can solve the problems of harsh preparation conditions, low production efficiency, long cycle, etc., achieve wide application prospects, low equipment requirements, and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

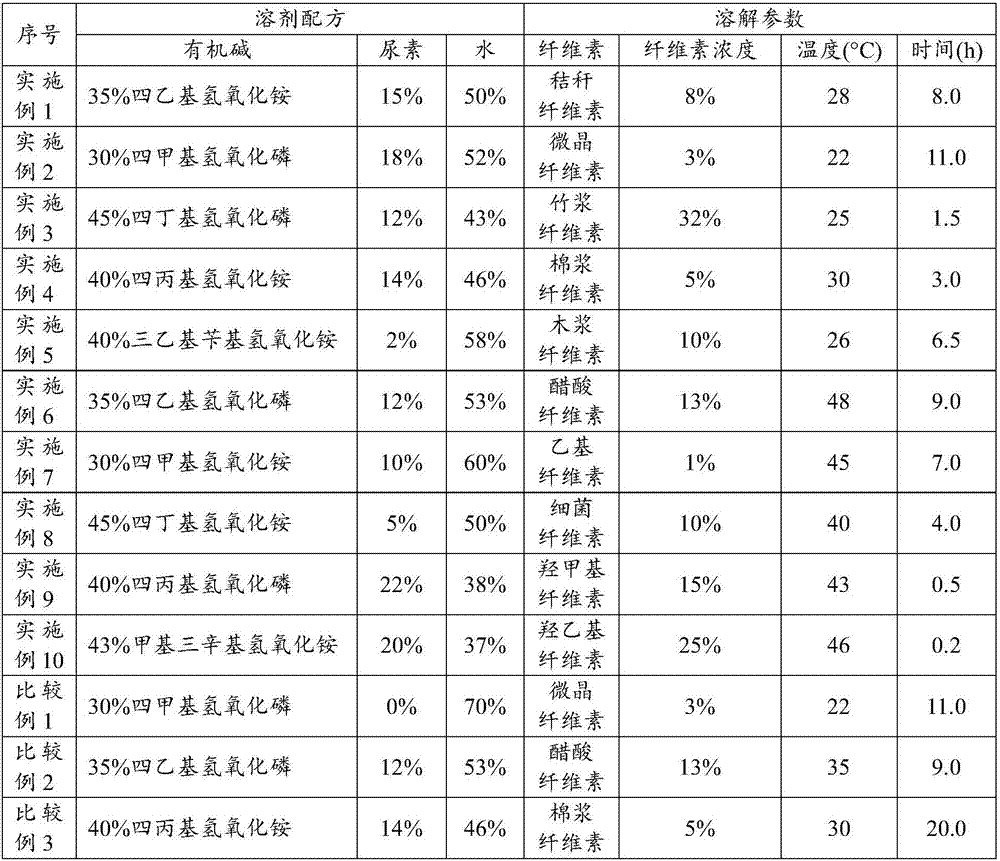

[0020] Specific embodiments of the present invention are given below to provide a further technical description of the technical solutions of the present invention. The process parameters of the embodiments and comparative examples are shown in Table 1. The general process steps are as follows:

[0021] First, prepare the cellulose solvent, configure each component of the solvent according to the formula and add it to the container, and form a homogeneous mixed solution by mechanical stirring at 25°C. Then a certain amount of cellulose is added to the solvent system and stirred at a certain temperature for a certain period of time to prepare a dispersion liquid containing the target cellulose nanocrystals.

[0022] Table 1. Example and comparative example process condition parameter table

[0023]

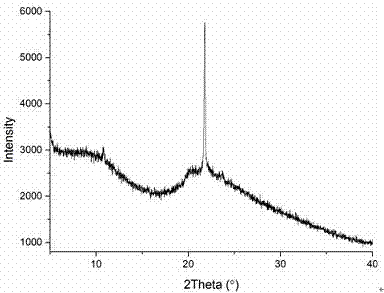

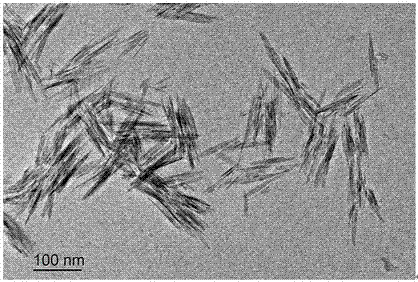

[0024] In the target solution sample obtained in the examples, the presence of cellulose nanocrystals can be observed through transmission electron microscopy. For the solution sample o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com