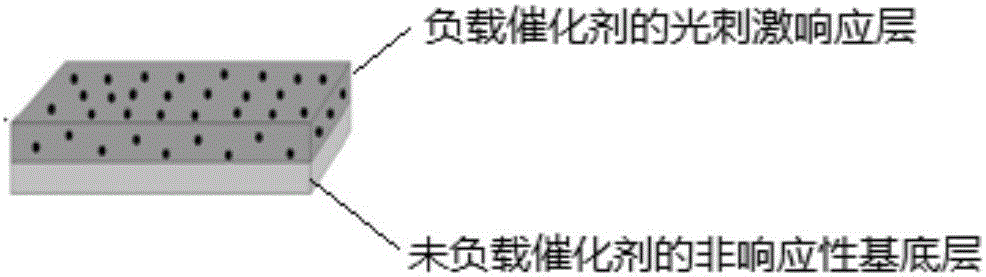

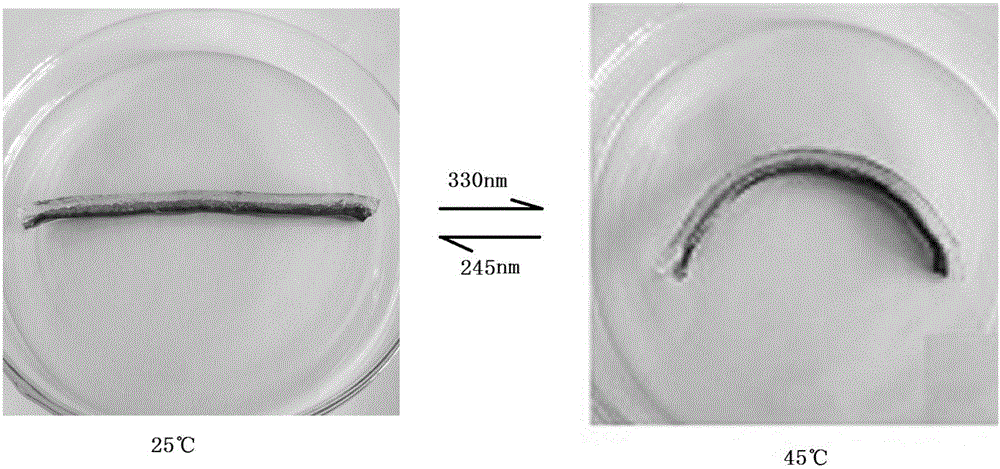

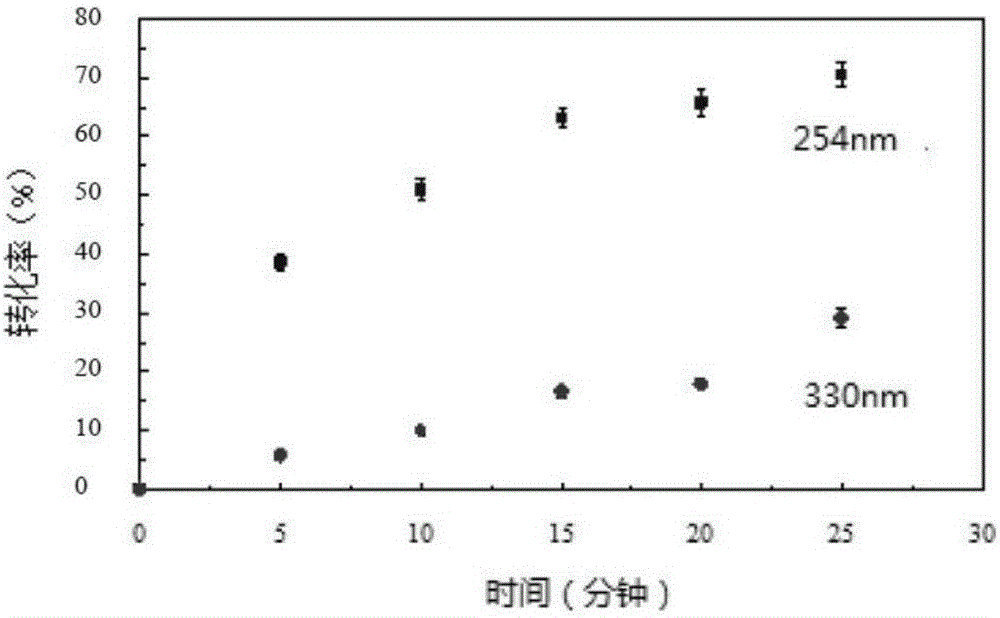

Photostimulation responsive intelligent catalytic material and preparation method thereof

A catalytic material and photo-stimulation technology, applied in chemical instruments and methods, catalyst protection, physical/chemical process catalysts, etc., can solve problems such as reduced surface energy, reduced catalytic activity, and easy agglomeration, so as to prevent aggregation and migration, Good protective effect, convenient and intuitive observation and judgment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Preparation of photo-stimuli-responsive layer loaded with catalyst nanoparticles:

[0025] 0.82g hydroxyethyl methacrylate cinnamate, 0.16g acrylamide, 0.24g silver nitrate and 0.01g N,N-methylenebisacrylamide were dissolved in 2.5ml dimethyl sulfoxide, then added 0.08g azo Diisobutyronitrile, ultrasonic treatment for 10min, after it was completely dissolved, reacted at 70°C for 2h. After the gel was polymerized, it was taken out, cooled to room temperature, and silver nitrate in the gel was reduced with 0.1 M sodium borohydride solution. Then the obtained gel was soaked in methanol, and the solvent was changed every 8 hours; after 2 days, it was soaked in deionized water, and the deionized water was changed every 8 hours, and the photostimuli-responsive layer loaded with catalyst nanoparticles was obtained after 2 days.

[0026] Preparation of smart catalytic materials with bilayer structure:

[0027] 0.4 g of acrylamide was dissolved in 1.5 mL of deionized water, an...

Embodiment 2

[0029] Preparation of photo-stimuli-responsive layer loaded with catalyst nanoparticles:

[0030] 0.76g of cinnamic acid hydroxyethyl methacrylate, 0.1g of acrylamide, 0.2g of silver nitrate and 0.01g of N,N-methylenebisacrylamide were dissolved in 2ml of dimethyl sulfoxide, and then 0.06g of azobis Isobutyronitrile, ultrasonic treatment for 20min, after it is completely dissolved, react at 60°C for 3h. After the gel was polymerized, it was taken out, cooled to room temperature, and silver nitrate in the gel was reduced with 0.1 M sodium borohydride solution. Then the obtained gel was soaked in methanol, and the solvent was changed every 8 hours; after 2 days, it was soaked in deionized water, and the deionized water was changed every 8 hours, and the photostimuli-responsive layer loaded with catalyst nanoparticles was obtained after 2 days.

[0031] Preparation of smart catalytic materials with bilayer structure:

[0032] 0.4 g of acrylamide was dissolved in 2 mL of deioniz...

Embodiment 3

[0034] Preparation of photo-stimuli-responsive layer loaded with catalyst nanoparticles:

[0035] 0.9g hydroxyethyl methacrylate cinnamate, 0.2g silver nitrate and 0.01g N,N-methylenebisacrylamide were dissolved in 2.5ml dimethyl sulfoxide, then 0.07g azobisisobutyronitrile ( ), sonicated for 10 min, and reacted at 65°C for 2 h after it was completely dissolved. After the gel was polymerized, it was taken out, cooled to room temperature, and silver nitrate in the gel was reduced with 0.1M sodium borohydride solution. Then the obtained gel was soaked in methanol, and the solvent was changed every 8 hours; after 2 days, it was soaked in deionized water, and the deionized water was changed every 8 hours, and the photostimuli-responsive layer loaded with catalyst nanoparticles was obtained after 2 days.

[0036] Preparation of smart catalytic materials with bilayer structure:

[0037] 0.4 g of acrylamide was dissolved in 3 mL of deionized water, and 0.03 g of divinylbenzene was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com