A kind of wood plasticizer and preparation method thereof

A plasticizer and wood technology, applied in wood treatment, wood processing appliances, wood treatment details and other directions, can solve the problems of material loss, large energy consumption, processing and even application scope limitations, large equipment investment, etc., to achieve production and use. Simple, convenient and safe, abundant material sources, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

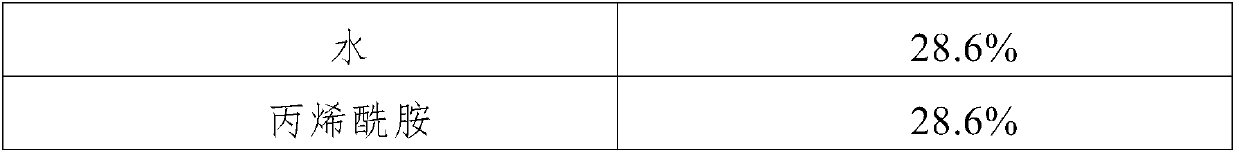

[0019] A kind of wood plasticizer, is made up of acrylamide, hydroxyethyl acrylate, acrylic acid, N-methylolacrylamide and water, and the weight percentage of each component is:

[0020]

[0021]

[0022] This embodiment also provides a preparation method of the wood plasticizer. The preparation method is as follows: add water into a stirring dissolution tank at normal temperature, and add acrylamide, hydroxyethyl acrylate, acrylic acid, N - Methylolacrylamide, until it is completely dissolved, then continue to stir for 5 to 10 minutes.

Embodiment 2

[0024] A kind of wood plasticizer, is made up of acrylamide, hydroxypropyl acrylate, methacrylic acid, N-methylolacrylamide and water, and the weight percentage of each component is:

[0025] water

[0026] This embodiment also provides a preparation method of the wood plasticizer. The preparation method is as follows: add water into a dissolving tank with stirring at room temperature, and add acrylamide, hydroxypropyl acrylate, and methacrylic acid in sequence while stirring. , N-methylolacrylamide, until it is completely dissolved, and then continue to stir for 5 to 10 minutes.

Embodiment 3

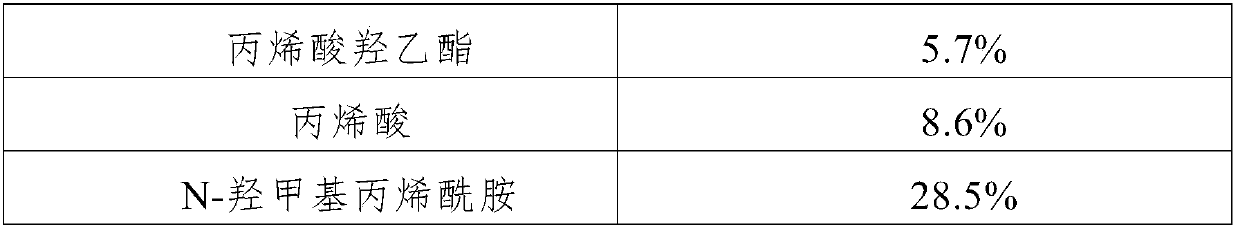

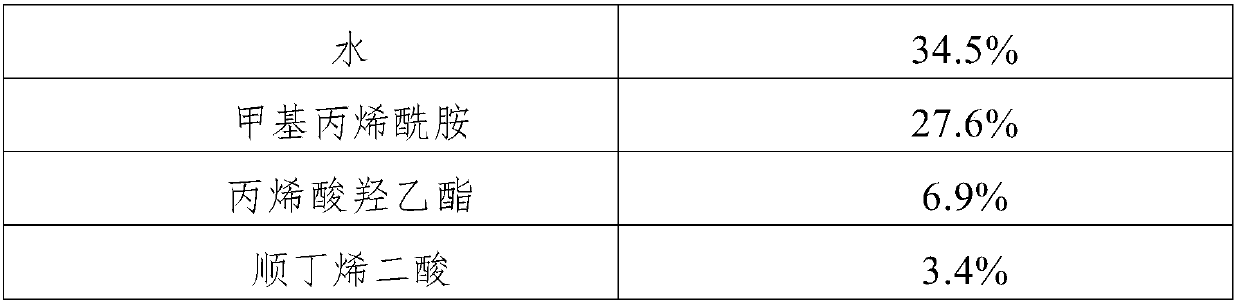

[0028] A kind of wood plasticizer, is made up of methacrylamide, hydroxyethyl acrylate, maleic acid, N-methylolacrylamide and water, and the weight percentage of each component is:

[0029]

[0030]

[0031] This embodiment also provides a preparation method of the wood plasticizer. The preparation method is as follows: add water into a stirring dissolution tank at room temperature, and add methacrylamide, hydroxyethyl acrylate, cis Butenedioic acid, N-methylolacrylamide, until completely dissolved, then continue to stir for 5 to 10 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com