Magnesium sulfate cement

A technology of magnesium sulfate and cement, which is applied in the field of cement, can solve the problems of poor bonding strength and easy corrosion, and achieve the effects of easy fixing and bonding, fine texture and fast forming speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

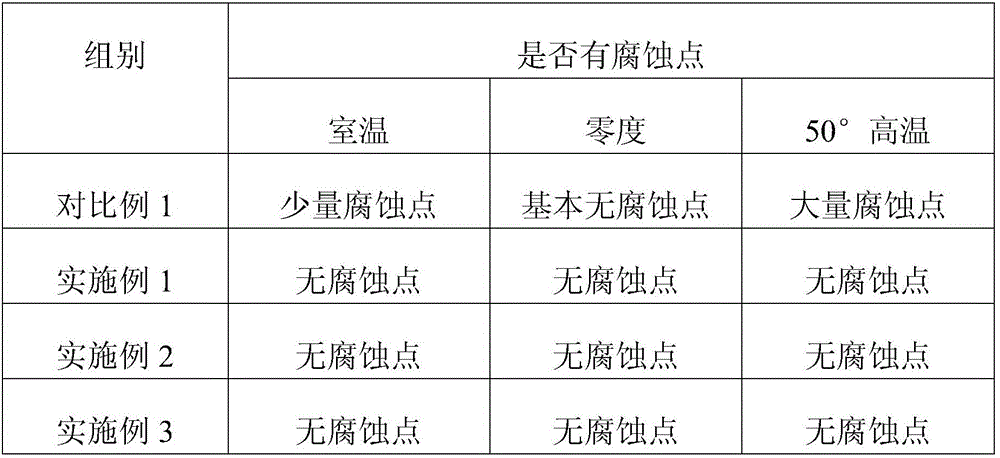

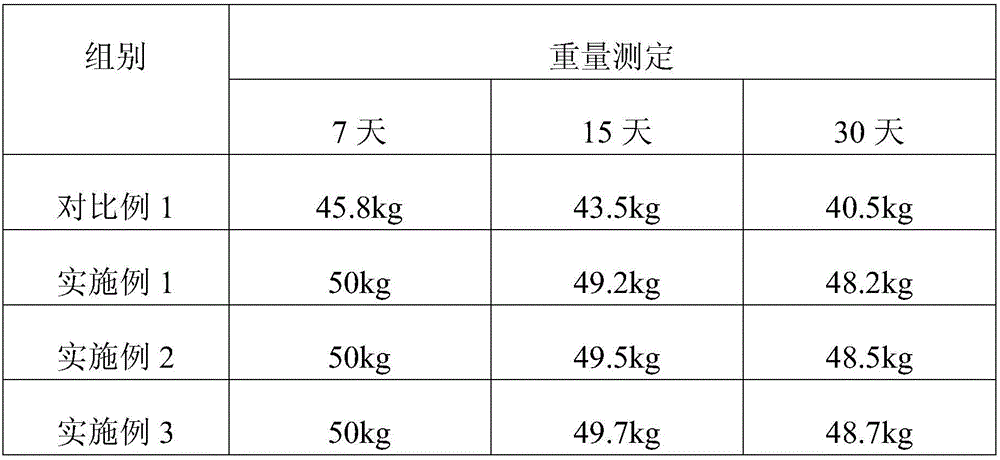

Examples

Embodiment 1

[0019] A magnesium sulfate cement according to a preferred embodiment of the present invention comprises the following components in parts by weight: 45 parts of fly ash, 10 parts of inorganic cementitious material, 10 parts of magnesium sulfate, 15 parts of plant fiber, and 15 parts of polypropylene fiber , 15 parts of blast furnace slag, 10 parts of iron powder, 20 parts of gypsum powder, 10 parts of graphite powder, 15 parts of aluminum oxide, 10 parts of carbide slag, 15 parts of alkali-resistant glass fiber, 20 parts of potassium aluminum sulfate, methyl silicate 3 parts of sodium, 3 parts of triethanolamine, 3 parts of coagulation regulator, 3 parts of water retention agent, 5 parts of activator and 5 parts of deformation inhibitor. Preferably, the plant fiber is bamboo fiber.

[0020] In this embodiment, the coagulation regulator is made of the following components in parts by weight: 10 parts of lithium slag powder, 5 parts of sodium gluconate, 0.5 parts of calcium amin...

Embodiment 2

[0030] A magnesium sulfate cement according to a preferred embodiment of the present invention comprises the following components by weight: 55 parts of fly ash, 15 parts of inorganic cementitious material, 15 parts of magnesium sulfate, 20 parts of plant fiber, and 20 parts of polypropylene fiber , 20 parts of blast furnace slag, 15 parts of iron powder, 25 parts of gypsum powder, 15 parts of graphite powder, 20 parts of aluminum oxide, 15 parts of carbide slag, 18 parts of alkali-resistant glass fiber, 25 parts of potassium aluminum sulfate, methyl silicate 7 parts of sodium, 6 parts of triethanolamine, 6 parts of coagulation regulator, 4 parts of water retention agent, 6 parts of activator and 6 parts of deformation inhibitor. Preferably, the plant fiber is bamboo fiber.

[0031] In this embodiment, the coagulation regulator is made of the following components in parts by weight: 15 parts of lithium slag powder, 7 parts of sodium gluconate, 0.8 parts of calcium aminoteasulfo...

Embodiment 3

[0041] A magnesium sulfate cement according to a preferred embodiment of the present invention comprises the following components by weight: 65 parts of fly ash, 20 parts of inorganic cementitious material, 20 parts of magnesium sulfate, 25 parts of plant fiber, and 25 parts of polypropylene fiber , 25 parts of blast furnace slag, 20 parts of iron powder, 30 parts of gypsum powder, 20 parts of graphite powder, 25 parts of aluminum oxide, 20 parts of carbide slag, 20 parts of alkali-resistant glass fiber, 30 parts of potassium aluminum sulfate, methyl silicate 8 parts of sodium, 8 parts of triethanolamine, 8 parts of coagulation regulator, 5 parts of water retention agent, 8 parts of activator and 8 parts of deformation inhibitor. Preferably, the plant fiber is bamboo fiber.

[0042] In this embodiment, the coagulation regulator is made of the following components by weight: 20 parts of lithium slag powder, 10 parts of sodium gluconate, 1 part of calcium aminoteasulfonate and 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com