Magnesium-calcium fire-proof plant fiber board and method of manufacturing the same

A plant fiber, magnesium and calcium technology, applied in the field of building materials, can solve the problems of waterproof, fireproof, anti-corrosion, poor moth resistance, environmental pollution, cost increase, etc., and achieves good weather resistance, quick effect, and low equipment investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with embodiment.

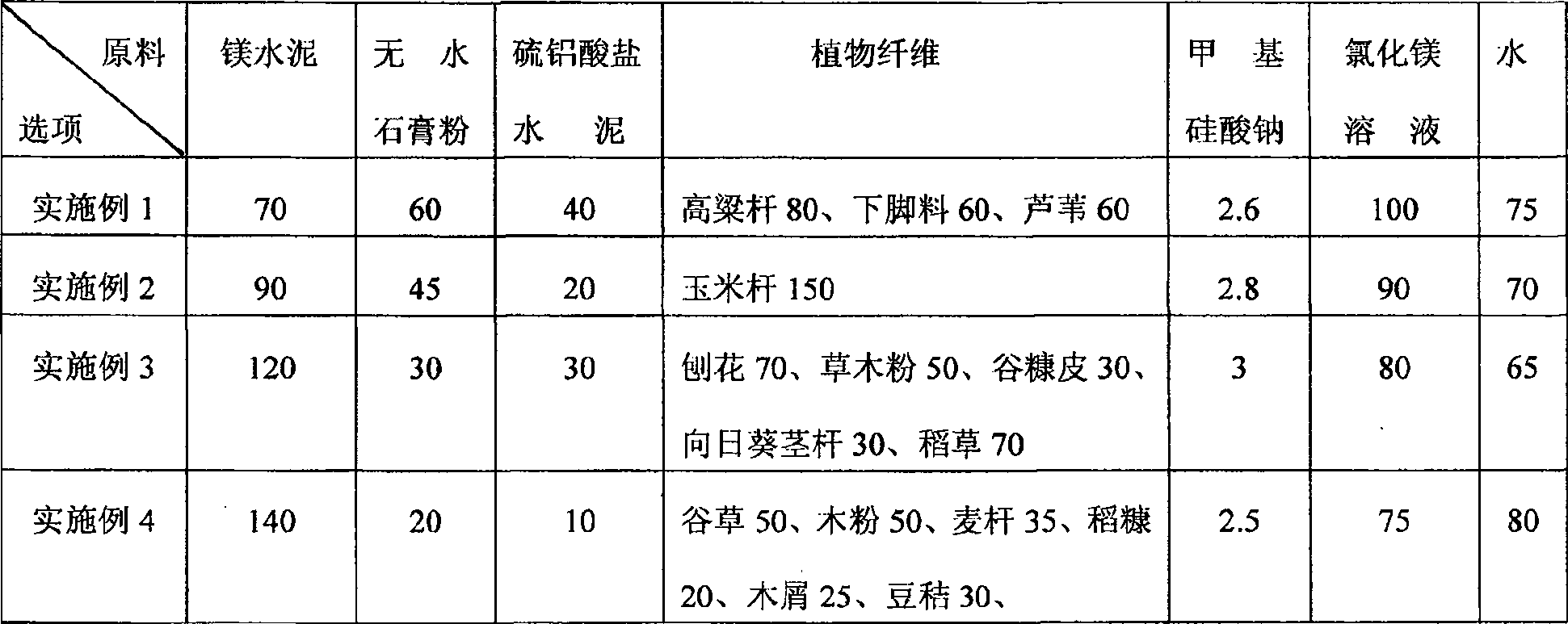

[0028] Magnesium-calcium fireproof plant fiberboard is composed of four parts: inorganic gelling material, plant fiber, sodium methyl silicate and stirring solution. Each raw material weight component is:

[0029] 1-2.4 parts of inorganic cementitious material, including: 0.7-1.4 parts of magnesium cement; 0.2-0.6 parts of anhydrous gypsum powder; 0.1-0.4 parts of sulphoaluminate cement. Magnesium cement is mainly used as a cementing agent. It is required that the magnesium cement must be high in silicon and low in calcium, and the active magnesium oxide should be between 62%±2. Its parameters are: MgO 80-86%, active CaO 1.0-1.5%, SiO 2 3.5~4.5%, Al 2 o 3 2.2~2.9%, Fe 3 o 4 1.0-2.0%; loss on ignition is 3-11%. 0.1-0.4 parts of sulphoaluminate cement, its function is early strength and waterproof.

[0030] 1.5-2.5 parts of plant fiber, including one or more of crop plant fib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com