Fungus-based biomass thermal-insulating material mainly prepared from wheat straw and preparation method of material

A technology of wheat straw and thermal insulation materials, applied in thermal insulation, fungi, building structures, etc., can solve problems such as environmental pollution and waste of resources, and achieve the effects of high freeze-thaw resistance, low production costs, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

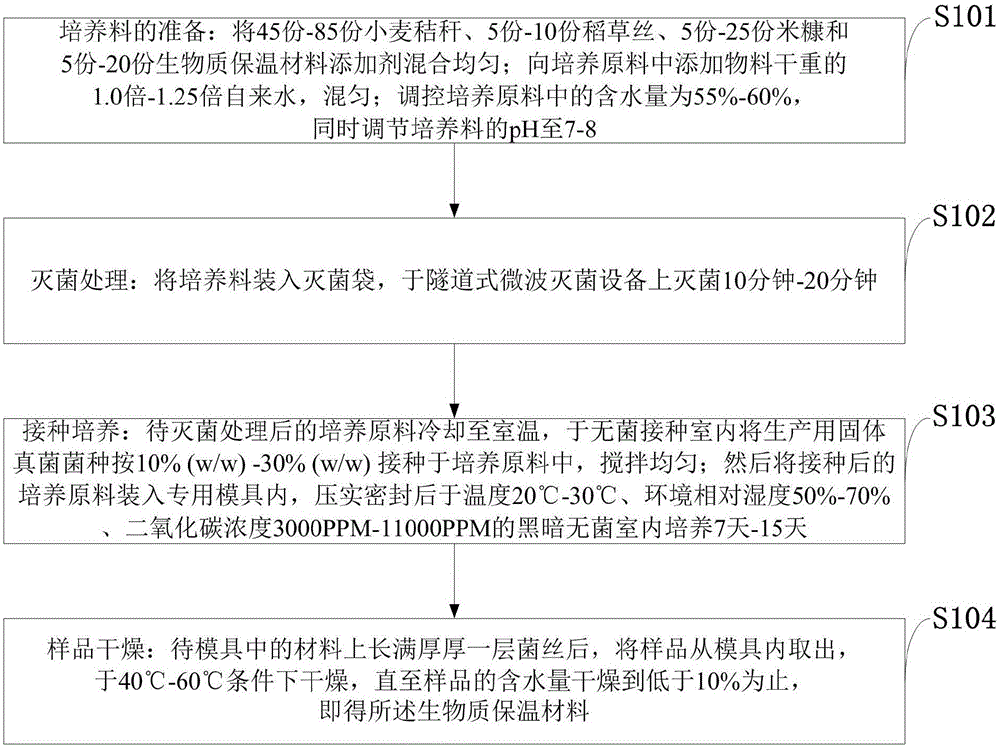

[0031] Such as figure 1 As shown, the preparation method of the fungal-based biomass insulation material with wheat straw as the main ingredient provided by the embodiment of the present invention includes the following steps:

[0032] S101: Preparation of culture material: Mix 45-85 parts of wheat straw, 5-10 parts of rice straw silk, 5-25 parts of rice bran and 5-20 parts of biomass insulation material additive; add materials to the culture raw material 1.0-1.25 times the dry weight of tap water, mix well; adjust the water content in the culture material to 55%-60%, and adjust the pH of the culture material to 7-8 at the same time;

[0033] S102: Sterilization treatment: put the culture material into a sterilization bag, and sterilize it on the tunnel microwave sterilization equipment for 10 minutes to 20 minutes;

[0034]S103: Inoculation and cultivation: the culture raw materials to be sterilized are cooled to room temperature, and the solid fungal strains for production ...

Embodiment 1

[0039] The specific steps of the preparation method of the fungal-based biomass insulation material with wheat straw as the main material provided by the embodiment of the present invention are as follows:

[0040] (1) Preparation of compost: mix 60 parts of wheat straw, 6 parts of rice straw, 20 parts of rice bran and 14 parts of biomass insulation material additive; add 1.25 times of tap water to the culture raw material, mix well; regulate The water content in the culture material is 60%, and the pH of the culture material is adjusted to 8 at the same time;

[0041] Wheat straw is soaked in 2% lime water for 24 hours, rinsed with water for 3 times, the length of wheat straw is 5mm-20mm, and the proportion of wheat straw with length of 5mm-10mm and 10mm-20mm is 57% and 43% respectively The rice straw silk is made by kneading rice straw, and the length is 10mm-30mm, and the proportions of the lengths of 10mm-20mm and 20mm-30mm are 60% and 40%.

[0042] (2) Sterilization trea...

Embodiment 2

[0047] The specific steps of the preparation method of the fungal-based biomass insulation material with wheat straw as the main material provided by the embodiment of the present invention are as follows:

[0048] (1) Preparation of compost: Mix 57 parts of wheat straw, 5 parts of rice straw, 20 parts of rice bran and 18 parts of biomass insulation material additive; add tap water 1.25 times the dry weight of the material to the culture raw material, mix well; control The water content in the culture material is 60%, and the pH of the culture material is adjusted to 7-8 at the same time;

[0049] Wheat straw is soaked in 1.5% lime water for 30 hours, rinsed with water for 3 times, the length of wheat straw is 5mm-20mm, and the proportion of wheat straw with length of 5mm-10mm and 10mm-20mm is 57% and 43% respectively The rice straw silk is made by kneading rice straw, and the length is 10mm-30mm, and the proportions of the lengths of 10mm-20mm and 20mm-30mm are 60% and 40%. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com