Application of Zedoary turmeric oil in preparation of camphor and isolation and extraction method of Zedoary turmeric oil

A technology of zedoary turmeric oil and camphor, which is applied in the field of extracting and preparing camphor from volatile oil of traditional Chinese medicine turmeric oil, can solve the problems of large environmental pollution, waste, and difficulty in realizing industrialized production, and achieves the effects of reducing manpower and material resources, simple preparation method and favorable industrialization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

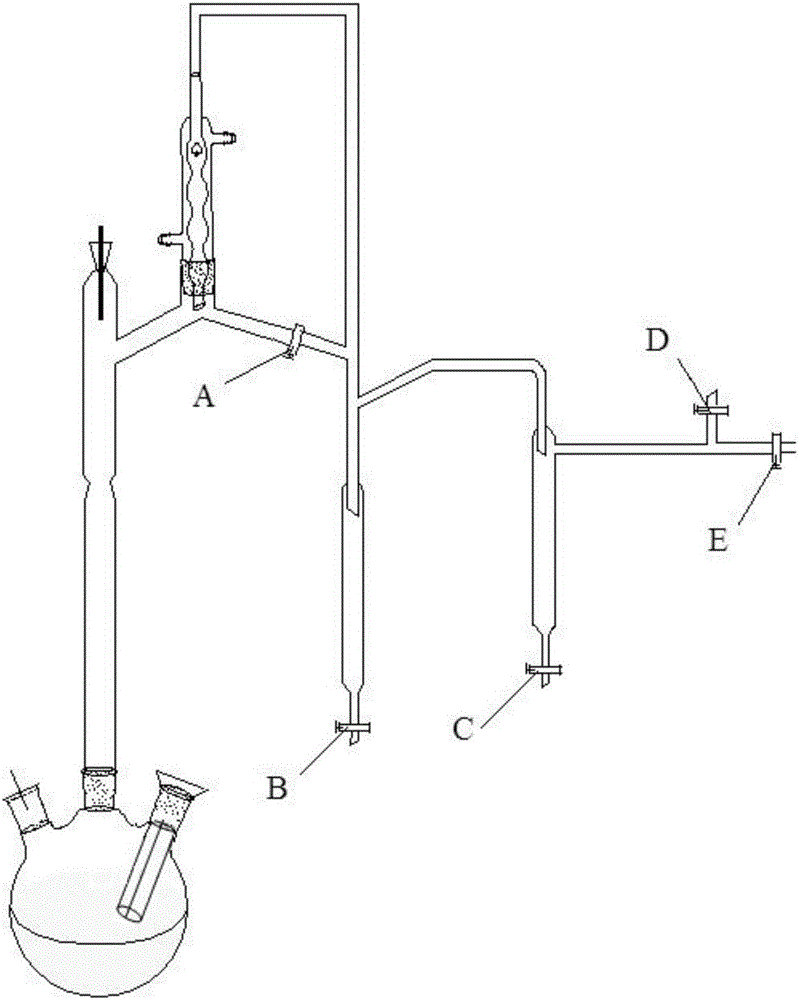

[0016] Get the zedoary oil and put it into a vacuum precision fractionation device (such as figure 1 ) in the tower kettle, close the A, B, C, D, E pistons of the device, the heating temperature of the tower kettle is controlled at 180°C, the column height is 1.5m, the inner diameter of the column is 150mm, and the packing is made of 4mmx4mm stainless steel mesh, the number of theoretical plates >50, the reflux ratio is 6:1, use the D and E pistons to control the vacuum degree of the decompression precision fractionation device to make the vacuum degree in the device reach 800Pa, and the C piston is used to control the outflow of the buffer device. When the column temperature is 55°C, a solid-liquid mixture begins to flow out from the condenser. Open the A piston and start collecting this section of fraction. When the temperature rises to 63°C, the solid-liquid mixture flows out completely, and this section of fraction is collected. Close A. Piston, open the B piston, take out...

Embodiment 2

[0018] Take turmeric oil and put it in the tower kettle of the decompression precision fractionation device, close the A, B, C, D, E pistons of the device, control the heating temperature of the tower kettle at 220°C, the column height is 1.5m, and the inner diameter of the column is 150mm. Packing made of mesh, theoretical plate number > 50, reflux ratio of 6:1, vacuum degree of 900Pa, when the column temperature is 65°C, a solid-liquid mixture begins to flow out from the condenser, open the A piston, and start to collect this section Distillate, until 72 ° C, the solid-liquid mixture flows out completely, and the fraction of this section is collected. Close the A piston, open the B piston, take out this fraction and filter, the filtered solid is washed several times with petroleum ether, and then recrystallized with 8 times the volume of ether-petroleum ether (2:11v / v) to obtain white crystal camphor , it is 93% to detect camphor content with gas chromatograph.

Embodiment 3

[0020] Take zedoary oil and put it in the tower kettle of the decompression precision fractionation device, close the A, B, C, D, E pistons of the device, control the heating temperature of the tower kettle at 240 °C, the column height is 1.5m, the column inner diameter is 150mm, and the column is made of 4mmx4mm stainless steel Packing made of mesh, theoretical plate number > 50, reflux ratio of 6:1, vacuum degree of 1000Pa, when the column temperature is 72°C, a solid-liquid mixture begins to flow out from the condenser, open the A piston, and start to collect this section Distillate, until 80 ° C, the solid-liquid mixture flows out completely, and the fraction of this section is collected. Close the A piston, open the B piston, take out the fraction and filter, the filtered solid is washed several times with petroleum ether, and then recrystallized with 6 times the volume of absolute ethanol to obtain white crystal camphor, and the content of camphor is detected by gas chrom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com