A kind of method for preparing lauryl betaine

A technology of dodecyl and dodecyldimethylamine, which is applied in the field of betaine, can solve problems such as failure to meet application requirements, corrosion, and impact on product costs, and achieve control of production costs, low prices, and reduced corrosion losses Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

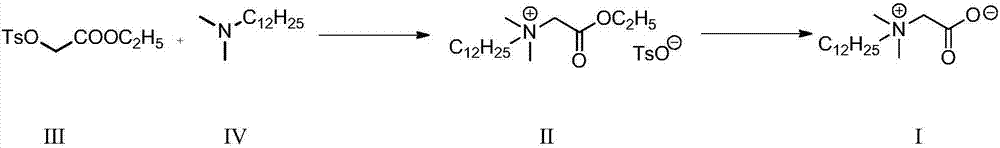

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: a kind of method for preparing lauryl betaine of this example, its steps are:

[0025] a. add 2-p-toluenesulfonyloxyethyl acetate (258g, 1.0mol) and acetone (2550g) in the three-necked flask that reflux condenser, thermometer, constant pressure dropping funnel and magnetic stirring device are housed, fully Stir well;

[0026] b. Add dodecyldimethylamine (255.6 g, 1.2 mol) dropwise to the mixture while stirring, heat up after the addition, keep the reaction mixture at 55-65°C, and fully stir the reaction for 16 hours;

[0027] c. After the substitution reaction finishes, after half of the solvent is distilled off under normal atmospheric pressure, add an aqueous solution (1290g) of 20% concentration of p-toluenesulfonic acid, and then continue to heat up and stir the reaction, keeping the temperature of the reaction mixture between 45-55°C During, fully stirred and reacted for 24 hours;

[0028] d. After the hydrolysis reaction is finished, remove the sol...

Embodiment 2

[0031] Embodiment 2: a kind of method for preparing lauryl betaine of this example, its steps are:

[0032] a. add 2-p-toluenesulfonyloxyethyl acetate (258g, 1.0mol) and acetone (1300g) in the three-necked flask that reflux condenser, thermometer, constant pressure dropping funnel and magnetic stirring device are housed, fully Stir well;

[0033] b. Add dodecyldimethylamine (213 g, 1.0 mol) dropwise to the mixture while stirring, heat up after the addition is complete, keep the reaction mixture at 55-65°C, and fully stir the reaction for 8 hours;

[0034] c. After the substitution reaction is finished, after half of the solvent is distilled off under normal atmospheric pressure, add an aqueous solution (1290g) of 15% concentration of p-toluenesulfonic acid, and then continue to heat up and stir the reaction, keeping the temperature of the reaction mixture between 45-55°C During, fully stirred and reacted for 8 hours;

[0035] d. After the hydrolysis reaction finishes, remove...

Embodiment 3

[0038] Embodiment 3: a kind of method for preparing lauryl betaine of this example, its steps are:

[0039] a. add 2-p-toluenesulfonyloxyethyl acetate (258g, 1.0mol) and acetone (1900g) in the three-necked flask that reflux condenser, thermometer, constant pressure dropping funnel and magnetic stirring device are housed, fully Stir well;

[0040] b. Add dodecyldimethylamine (234.3 g, 1.1 mol) dropwise to the mixture while stirring, heat up after the addition, keep the reaction mixture at 55-65°C, and fully stir the reaction for 12 hours;

[0041] c. After the substitution reaction finishes, after half of the solvent is distilled off under normal atmospheric pressure, add an aqueous solution (1290g) of 18% concentration of p-toluenesulfonic acid, and then continue to heat up and stir the reaction, keeping the temperature of the reaction mixture between 45-55°C During, fully stirred and reacted for 16 hours;

[0042] d. After the hydrolysis reaction finishes, remove the solven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com