Technology for synthesizing glycol dibenzenesulfonate from nano-solid alkali catalyst

A technology of ethylene glycol dibenzenesulfonate and solid base catalyst, which is applied in the direction of physical/chemical process catalyst, sulfonate ester preparation, metal/metal oxide/metal hydroxide catalyst, etc., and can solve the problem of glycol diphenylsulfonate The sulfonate process route is complex and the yield is not good, etc., to achieve the effects of easy acquisition, reduced side reactions, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

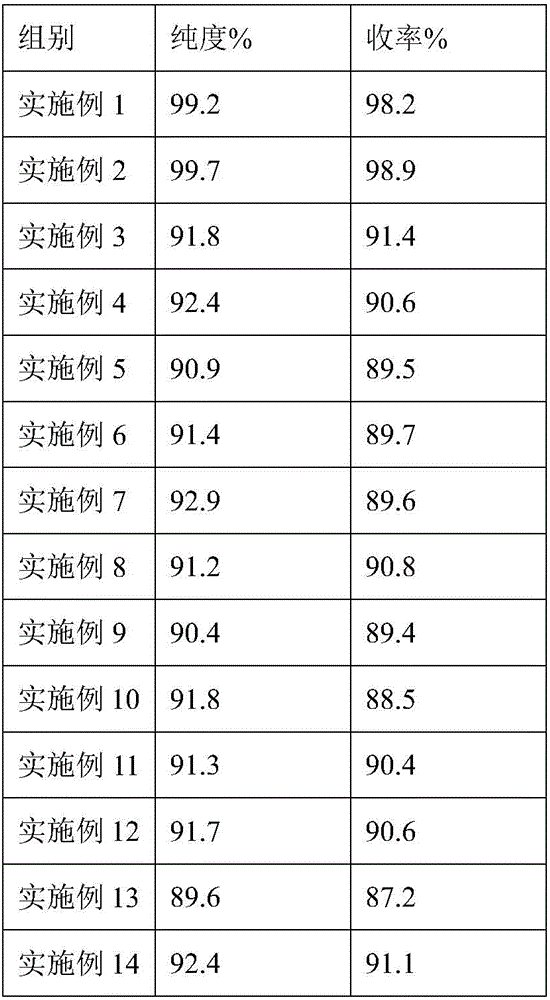

Examples

Embodiment 1

[0021] Cesium-modified nano-scale Ti / Al composite solid base catalyst, the preparation process is as follows:

[0022] Step 1. Treat alumina and titanium dioxide under ultrasonic waves for 2 hours;

[0023] Step 2, then calcining treatment: first calcining in air at 500°C and 0.2kpa for 4h, then calcining in nitrogen at 600°C and 0.4kpa for 3h;

[0024] Step 3, after the calcination, purging under helium atmosphere for 3h;

[0025] Step 4, then introduce cesium element by impregnation method: mix 10g of alumina and 5g of titanium dioxide in a mass ratio of 2:1, and then immerse in 0.5mol / L Cs2CO3 solution for 12h;

[0026] Step 5, then use hot alkali treatment, treat it under hot air at 180°C for 2h, then soak it in 5% sodium hydroxide solution for 5h, and then transfer it to a beaker;

[0027] Step 6. Perform coupling treatment: add 0.05mol coupling agent kh500 dropwise to the mixture after hot alkali treatment, and magnetically stir while adding;

[0028] Step 7, adding 0...

Embodiment 2

[0037] Example 2 Prepare glycol, benzenesulfonyl chloride, and self-made cesium-modified nano-scale Ti / Al composite solid base catalyst with a mass ratio of 26:100:0.5. Glycol 26g, benzenesulfonyl chloride 100g, self-made cesium-modified nano-scale Ti / Al composite solid base catalyst 0.5g. Pyridine 1.1mol, chloroform 160ml. The operation steps are the same as in Example 1.

Embodiment 3

[0038] Example 3 Prepare glycol, benzenesulfonyl chloride, and self-made cesium-modified nano-scale Ti / Al composite solid base catalyst with a mass ratio of 18:105:0.5. Glycol 18g, benzenesulfonyl chloride 105g, self-made cesium-modified nano-scale Ti / Al composite solid base catalyst 0.5g. Other raw materials, operation steps are the same with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com