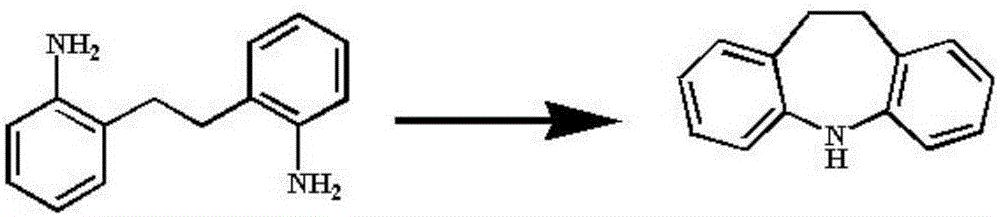

Method for catalytic synthesis of iminodibenzyl

A technology of iminodibenzyl and catalyst, which is applied in the field of preparation of iminodibenzyl, can solve the problems of raw material and product decomposition, low yield, poor product quality, etc., and achieve low production cost, high catalytic yield, and remarkable energy saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] One, catalyst preparation embodiment

[0018] Weigh 500 g of amorphous silicon-aluminum molecular sieve microspheres with a silicon-aluminum ratio of 10:1, add them to 1 L of concentrated phosphoric acid, stir and soak at room temperature for 6 hours. The impregnated silica-alumina molecular sieve was filtered out, dried, and calcined in a muffle furnace at 600° C. for 4 hours. After roasting, continue soaking in phosphoric acid, drying and roasting, this process is repeated three times to increase the loading capacity of phosphoric acid. After the catalyst is prepared, it is crushed into particles with a particle diameter of 1-2 mm.

[0019] Two, catalytic deamination embodiment

[0020] Fill the pulverized catalyst into a fixed-bed reaction tube with a diameter of 1.5 cm and a length of 20 cm and heat it to 300°C. The flow rate of distilled water is 5mL / min through the constant liquid sampling pump, and it is input into the high-temperature steam generator, and is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com