Biodegradable additive and plastic products with addition of additive

A biodegradable and additive technology, applied in the field of polyethylene plastic film, can solve the problems of tensile strength, elongation at break, burst and tear strength, light transparency, low wet strength, high production cost, and poor physical and mechanical properties And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] Preparation of biodegradable additives

[0022] The biodegradable additive of the present invention is prepared from the following raw materials: 8-12% by mass of copper powder with a particle size below 3 microns, 8-12% by mass of iron powder with a particle size below 3 microns, and 0.5-1.5% by mass of silane coupling agent %, 0.5-1.0% by mass of titanic acid coupling agent, and the balance is low-density polyethylene.

[0023] According to a further preferred embodiment of the present invention, the consumption of copper powder is 10 mass %, the consumption of iron powder is 10 mass %, and the silane coupling agent is 3-aminopropyltriethoxysilane, and its consumption is 1 mass % %, the titanic acid coupling agent is isopropyl tris (dioctyl pyrophosphate acyloxy) titanate, and its consumption is 0.6 mass %, and low-density polyethylene is low-density polyethylene with a lower melting point, and its consumption is 78.4% by mass, and prepared through the following st...

Embodiment 1

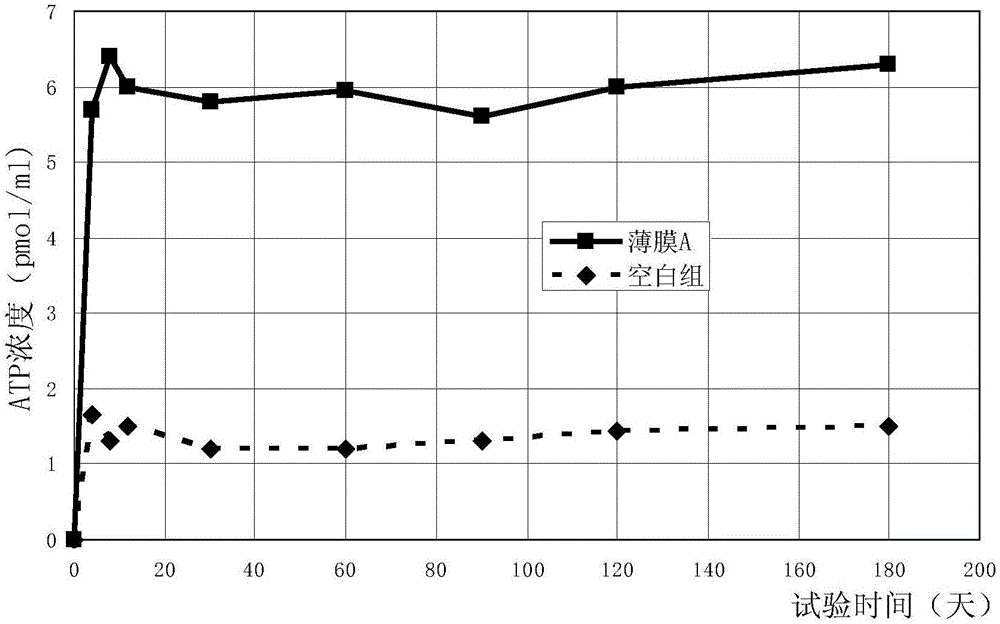

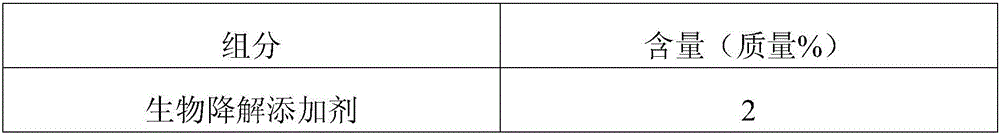

[0029] Biodegradable polyethylene film A

[0030] Table 1: Composition of biodegradable polyethylene film A

[0031]

[0032]

[0033] After fully mixing the components and materials shown in Table 1, put them into a single-screw extruder (the length-to-diameter ratio of the extruder is 20-30), and blow into a biodegradable film with a thickness of 25 microns.

Embodiment 2

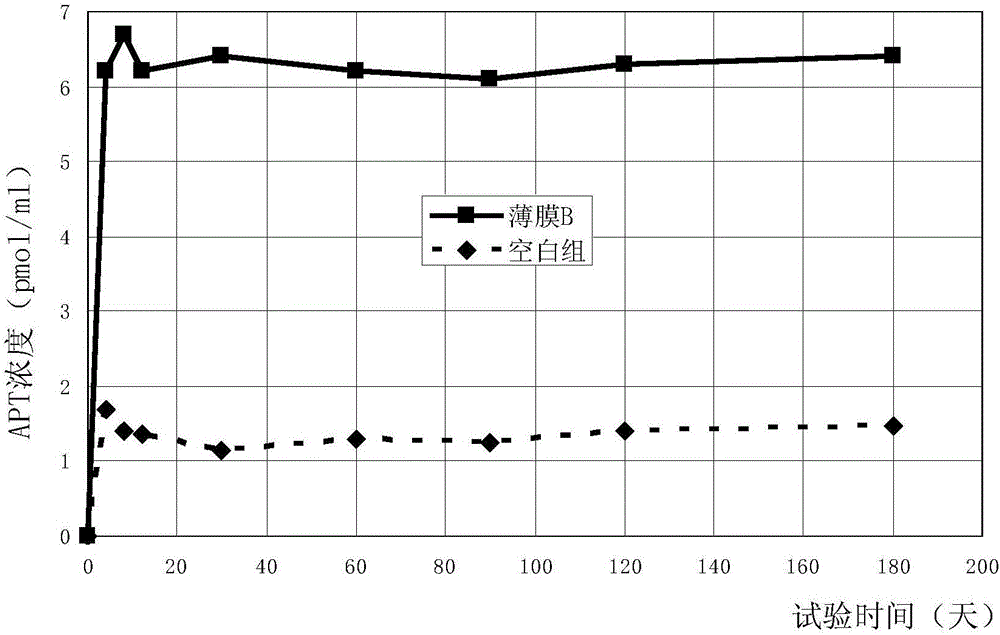

[0035] Biodegradable polyethylene film B

[0036] Table 2: Composition of biodegradable polyethylene film A

[0037] components Content (mass%) Biodegradable Additives 10 calcium carbonate powder 3 LDPE 87

[0038] Except that the component contents are shown in Table 2, the film-making process is the same as above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com