A kind of combined ferromanganese production method using pyrite to strengthen the reduction of pyrolusite

A joint production and pyrolusite technology, which is applied in the field of metallurgy and mineral processing, can solve the problems of large dust content, low concentration of tail gas reducing agent, and difficult industrial practice, etc., and achieves low price, thorough reaction, and low difficulty in impurity removal Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

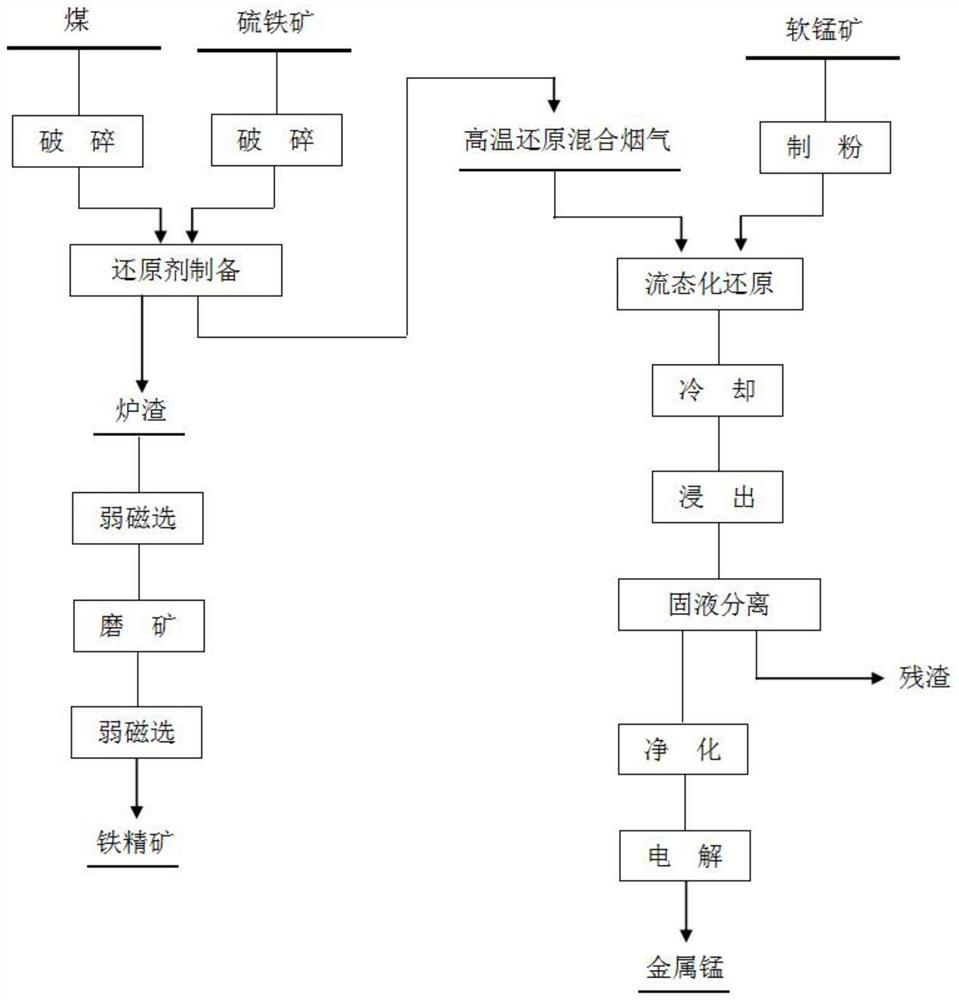

[0032] Such as figure 1 Shown, a kind of ferromanganese combined production method utilizing pyrite to strengthen pyrolusite reduction comprises the following steps:

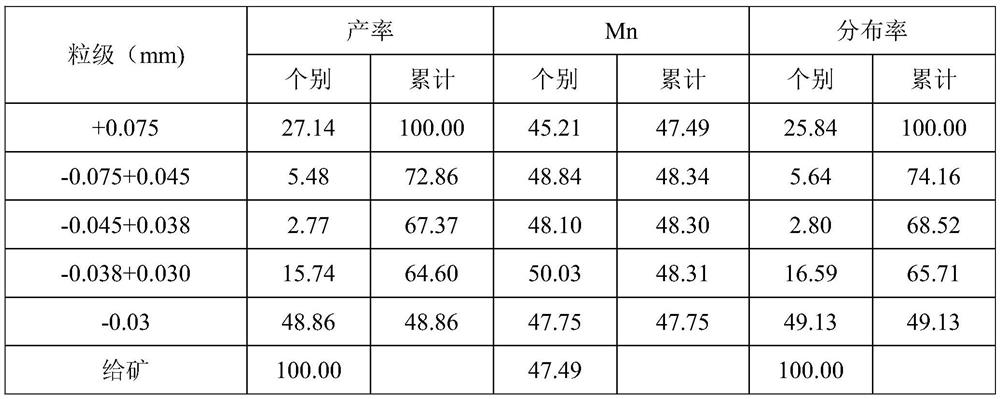

[0033] (1) Crush coal and pyrite (compositions are shown in Table 1 and Table 2 below) and mix them uniformly at a mass ratio of 80:20, then add them to the gasifier for roasting to obtain SO-containing 2 、H 2 , CO high-temperature mixed flue gas, SO in high-temperature mixed flue gas 2 、H 2 and CO concentrations are about 3%, 4% and 8% respectively; collect slag to obtain magnetite, and magnetite is subjected to magnetic separation to obtain iron concentrate;

[0034] (2) First, use a weak magnetic machine to carry out a weak magnetic separation on the cooled magnetite to obtain a weak magnetic coarse concentrate and a weak magnetic tailing. After a weak magnetic coarse concentrate is demagnetized, it enters the grinding and classification operation. The tailings of the first stage of weak magnetic tailings...

Embodiment 2

[0048] The coal powder, pyrite and pyrolusite used in this example are the same as in Example 1, the difference is that the coal powder and pyrite are crushed and mixed evenly according to the mass ratio of 90:10, and then added to the gasifier After internal calcination, the SO-containing 2 、H 2 , CO high-temperature mixed flue gas, SO in high-temperature mixed flue gas 2 、H 2 and CO concentrations were about 2.2%, 5.3% and 10.7%, respectively. After the same process as in Example 1, the temperature of the exhaust gas is about 180°C.

[0049] In this example, the grade of the finally obtained iron ore concentrate is 66.41%, the iron recovery rate is 91.42%, the Mn content of the electrolytic manganese product is ≥ 99.8%, and the product quality meets the national DJMn D-level quality requirements.

Embodiment 3

[0051] The coal powder, pyrite and pyrolusite used in this example are the same as in Example 1, the difference is that after the pulverized coal and pyrite are crushed, they are mixed evenly in a mass ratio of 80:20, and 10% of coal quality is added. % sulfur powder, after roasting in the gasifier, get SO 2 、H 2 , CO high-temperature mixed flue gas, SO in high-temperature mixed flue gas 2 、H 2 and CO concentrations are about 3.2%, 4.5% and 9.9%, respectively. After the same process as in Example 1, the temperature of the exhaust gas is about 160°C.

[0052] In this example, the iron ore concentrate grade finally obtained is 66.55%, the iron recovery rate is 91.98%, the yield of manganese sulfate is higher than that of Example 1-2, the Mn content of the electrolytic manganese product is ≥ 99.8%, and the product quality reaches the national DJMn D-level quality requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com