Degradable environment-friendly safe preservative film and preparation method thereof

A kind of fresh-keeping film and safety technology, which is applied in the field of degradable, environmentally friendly and safe fresh-keeping film and its preparation, can solve the problems of reducing product quality, unfavorable environmental protection, poor strength, etc., so as to improve the mixing uniformity, reduce the number of bubbles, and improve crystallization. low degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of degradable environment-friendly and safe fresh-keeping film, formula comprises: PLA masterbatch, PHA masterbatch, PVA masterbatch, plasticizer, antifoaming agent, antibacterial agent, antifogging agent and white oil, the parts by weight of each component They are: 70 parts of PLA masterbatch, 20 parts of PHA masterbatch, 10 parts of PVA masterbatch, 1 part of plasticizer, 0.1 part of defoamer, 2 parts of antibacterial agent, 1 part of antifogging agent and 0.1 part of white oil, and the plasticizer is one or more mixtures of glycerin, sorbitol and oligomer PEG, and the defoamer is silicone ether copolymerized defoamer, modified polydimethylsiloxane and one or more mixtures of polyoxyethylene oxypropylene glycerin, and the antibacterial agent is inorganic antibacterial powder BC36.

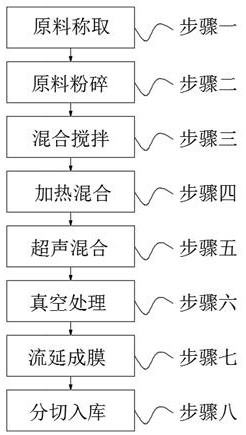

[0032] A method for preparing a degradable, environmentally friendly and safe plastic wrap, comprising the following steps: step 1, weighing raw materials; step 2, crushing raw mat...

Embodiment 2

[0042]A kind of degradable environment-friendly and safe fresh-keeping film, formula comprises: PLA masterbatch, PHA masterbatch, PVA masterbatch, plasticizer, antifoaming agent, antibacterial agent, antifogging agent and white oil, the parts by weight of each component They are: 80 parts of PLA masterbatch, 25 parts of PHA masterbatch, 20 parts of PVA masterbatch, 3 parts of plasticizer, 0.15 parts of defoamer, 5 parts of antibacterial agent, 4 parts of antifogging agent and 0.3 parts of white oil, and the plasticizer is one or more mixtures of glycerin, sorbitol and oligomer PEG, and the defoamer is silicone ether copolymerized defoamer, modified polydimethylsiloxane and one or more mixtures of polyoxyethylene oxypropylene glycerin, and the antibacterial agent is inorganic antibacterial powder BC36.

[0043] A method for preparing a degradable, environmentally friendly and safe plastic wrap, comprising the following steps: step 1, weighing raw materials; step 2, crushing raw...

Embodiment 3

[0053] A kind of degradable environment-friendly and safe fresh-keeping film, formula comprises: PLA masterbatch, PHA masterbatch, PVA masterbatch, plasticizer, antifoaming agent, antibacterial agent, antifogging agent and white oil, the parts by weight of each component They are: 78 parts of PLA masterbatch, 22 parts of PHA masterbatch, 15 parts of PVA masterbatch, 2 parts of plasticizer, 0.12 parts of defoamer, 3 parts of antibacterial agent, 2.5 parts of antifogging agent and 0.2 parts of white oil, and the plasticizer is one or more mixtures of glycerin, sorbitol and oligomer PEG, and the defoamer is silicone ether copolymerized defoamer, modified polydimethylsiloxane and one or more mixtures of polyoxyethylene oxypropylene glycerin, and the antibacterial agent is inorganic antibacterial powder BC36.

[0054] A method for preparing a degradable, environmentally friendly and safe plastic wrap, comprising the following steps: step 1, weighing raw materials; step 2, crushing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com