A kind of multi-component toughening modified pp-r pipe special material and preparation method thereof

A special material for pipes, PP-R technology, which is applied in the field of polymer materials, can solve the problems of not really improving the comprehensive performance of PP-R pipes, limited application scope, prone to brittle fracture, etc. Performance improvements, the effect of improving interface performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

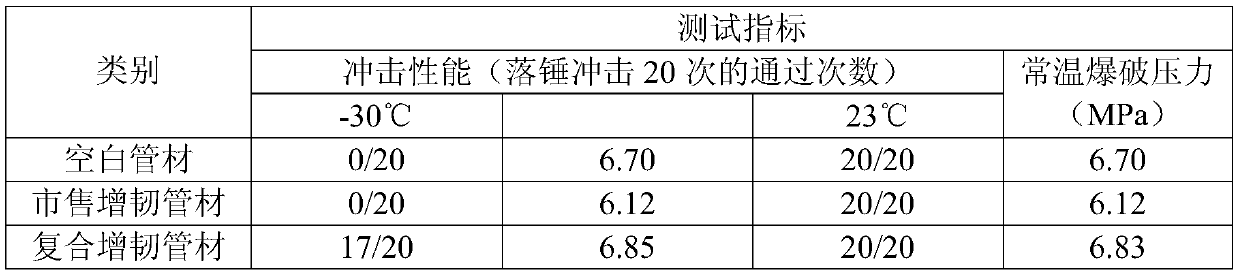

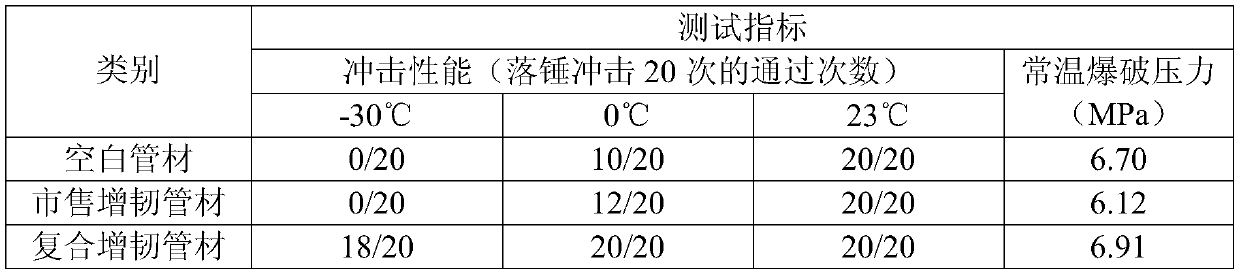

Examples

preparation example Construction

[0028] The embodiment of the present invention also provides a method for preparing a multi-component toughened modified PP-R pipe special material, which includes the following steps:

[0029] A), prepare toughening agent I, toughening agent II and inorganic rigid particles:

[0030] a1) Preparation of toughening agent I: select TMB series compounds, CHB-5 compounds, NU-100 compounds and NAB compounds, rare earth β nucleating agents as WGB series compounds, organic acid β nucleating agents as DCHT compounds, One or more of hydrazine diacid and suberic acid are used as β-nucleating agent, fully pre-mixed with PP-R resin in proportion, and then the pre-mixed material is placed in a twin-screw extrusion granulator for Blend molding, cooling, and pelletizing to obtain the toughening agent I, which is set aside.

[0031] Among them, the sufficient premixing of the β-nucleating agent and PP-R resin means that the β-nucleating agent is uniformly dispersed in the PP-R material by us...

Embodiment 1

[0039] A multi-component toughened and modified PP-R pipe special material, the raw material unit is 55-95 parts of PP-R resin, 2-20 parts of toughening agent I, and 1-20 parts of toughening agent II. 5 parts, 2 to 20 parts of inorganic rigid particles, the raw materials are configured within the range.

[0040] The PP-R resin is random copolymerized polypropylene, brand: PA14-D, PetroChina Daqing Oilfield Co., Ltd. (the PP-R resins described below are all resins of this brand), and the content is 78 parts.

[0041] Toughening agent I content is 2 parts, and its composition is PP-R resin and β nucleating agent. Based on 100 parts by weight of the toughening agent I, wherein, the content of PP-R resin is 95 parts, and the beta nucleating agent is an aromatic amide compound (TMB) with a content of 5 parts. Trademark: TMB-5, Shanxi Chemical Industry graduate School.

[0042] The content of toughening agent II is 10 parts, and its composition is PP-R resin, elastomer and compati...

Embodiment 2

[0050] A multi-component toughening modified PP-R pipe special material, the raw material unit is 55-95 parts of PP-R resin, 1-5 parts of toughening agent I, and 2-5 parts of toughening agent II. 20 parts, inorganic rigid particles are 2 to 20 parts, and the raw materials are configured within the range.

[0051] PP-R resin is random copolymerized polypropylene with a content of 83 parts.

[0052] Toughening agent I content is 2 parts, and its composition is PP-R resin and nucleating agent. Based on 100 parts by weight of toughening agent I, wherein, the content of PP-R resin is 95 parts, and the beta nucleating agent is an aromatic amide compound (NAB), with a content of 5 parts. Trademark: NAB-82, Shanxi Chemical Industry graduate School.

[0053] The content of toughening agent II is 5 parts, and its composition is PP-R resin, elastomer and compatibilizer. Based on 100 parts by weight of toughening agent II, wherein, the content of PP-R resin is 80 parts, the elastomer i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com