Low-cost mono-component rapidly-solidified liquid epoxy resin composition for fiber composite materials

A technology of liquid epoxy resin and fiber composite material, which is applied in the manufacturing field of carbon fiber composite material parts in the automobile industry, can solve problems such as long curing time, and achieve the effects of good heat resistance, reduced requirements and excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0021] Weigh in parts by weight,

[0022] Resin:

[0023] NPEF-170 Bisphenol F epoxy resin 100 parts

[0024] NPEL-127 bisphenol A epoxy resin 30 parts

[0025] Hardener:

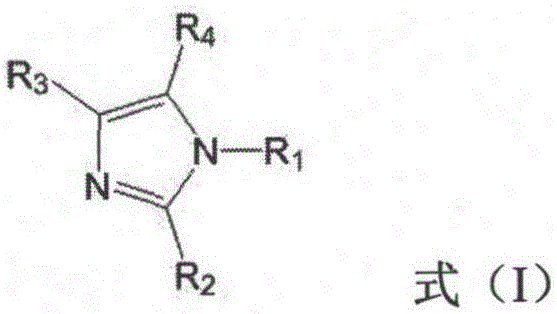

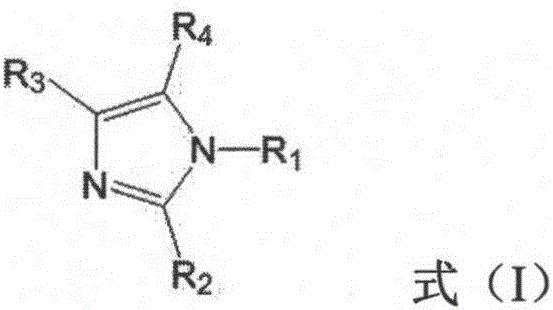

[0026] 1-cyanoethyl-2-methyl-4-ethylimidazole 4 parts

[0027] Thinner:

[0028] NPES-907 15 copies

[0029] Toughening agent:

[0030] Wuhan Longtu new material LT-EP toughening agent 2 parts

[0031] Preparation:

[0032] At room temperature, mix NPEL-170 bisphenol F epoxy resin, NPEF-127 bisphenol A epoxy resin, diluent NPES-907 and Wuhan Longtu new material LT-EP toughening agent according to the weight ratio and mix uniformly. Add the corresponding weight fraction of 1-cyanoethyl-2-methyl-4-ethylimidazole, and vacuum degas for 15 minutes while stirring. The curing condition of the epoxy resin is heating at 120°C for 15 minutes.

[0033] The main technical indicators of the epoxy resin composition before and after curing are as follows:

[0034] Through the differential thermal scanning analysis (DSC) test (from 20℃ to...

example 2

[0036] Weigh in parts by weight

[0037] Resin:

[0038] SM-128 Bisphenol A epoxy resin 20 parts

[0039] NPEL-127 80 copies

[0040] Hardener:

[0041] 2-ethyl-4-methylimidazole 5 parts

[0042] Thinner:

[0043] SYNASIA S-510 10 copies

[0044] Toughening agent:

[0045] Wuhan Longtu new material LT-EP toughening agent 2 parts

[0046] Preparation:

[0047] At room temperature, mix SM-128 bisphenol A epoxy resin, NPEL-127 bisphenol A epoxy resin, and Wuhan Longtu New Material LT-EP toughening agent evenly by weight ratio, and add the corresponding amount of 2 during the mixing process. -Ethyl-4-methylimidazole, and vacuum degassing for 15 minutes while stirring.

[0048] The main technical indicators of the one-component fast curing liquid molding epoxy resin prepared by the above method at 120°C are as follows:

[0049] Through the DSC test, the initial curing temperature is 103.4°C, the curing exotherm is 378.6J / g, and the curing time is 5 minutes at 120°C. Through the DSR test, the gel t...

example 3

[0051] Weigh in parts by weight

[0052] SM-128 bisphenol A epoxy resin 50 parts

[0053] NPEL-127 bisphenol A epoxy resin 30 parts

[0054] 1-cyanoethyl-2-methyl-4-ethylimidazole 4 parts

[0055] Thinner:

[0056] SYNASIA S-400 10 copies

[0057] Toughening agent:

[0058] Jiadida Chemical CTBN1300X13 toughening agent 2 parts

[0059] Preparation:

[0060] At room temperature, mix SM-128 bisphenol A epoxy resin, NPEL-127 bisphenol A epoxy resin, SYNASIA S-400, Jiadida Chemical CTBN1300X13 toughening agent according to the weight ratio, and the weight ratio during the mixing process Add 1-cyanoethyl-2-methyl-4-ethylimidazole and vacuum degas for 15 minutes while stirring.

[0061] The main technical indicators of the one-component fast curing liquid molding epoxy resin prepared by the above method at 120°C are as follows:

[0062] Through the DSC test, the initial curing temperature is 116.4°C, the curing exotherm is 385.6J / g, and the curing time is 3.7 minutes at 120°C. Passed the DSR test...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com