Integrated cross-flow type lithium redox flow battery reactor

A technology for flow batteries and reactors, which is applied to fuel cells, electrochemical generators, battery pack components, etc., can solve the problem of stacking structure, heavy weight of end plates and tie rods, reducing the weight-to-weight ratio of battery reactors, and affecting battery power. Reactor service life and other issues, to achieve the effect of reducing battery cost, convenient assembly, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

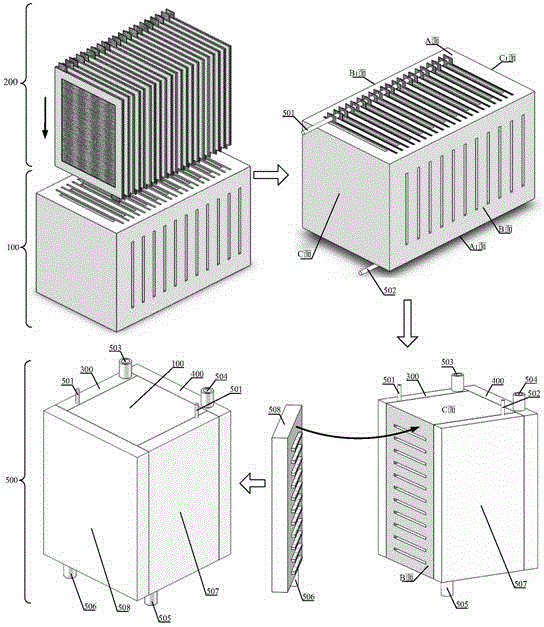

[0038] In this embodiment, a 1kW-10kW integrated cross-flow lithium flow battery reactor 500 is provided, including a battery frame 100, an isolation window 200, a positive electrode manifold 300, a negative electrode manifold 400, a positive manifold 507, and a negative manifold 508 , positive electrode guide rod 501 , negative electrode guide rod 502 , positive electrode liquid inlet 503 , positive electrode liquid outlet 505 , negative electrode liquid inlet 504 , and negative electrode liquid outlet 506 .

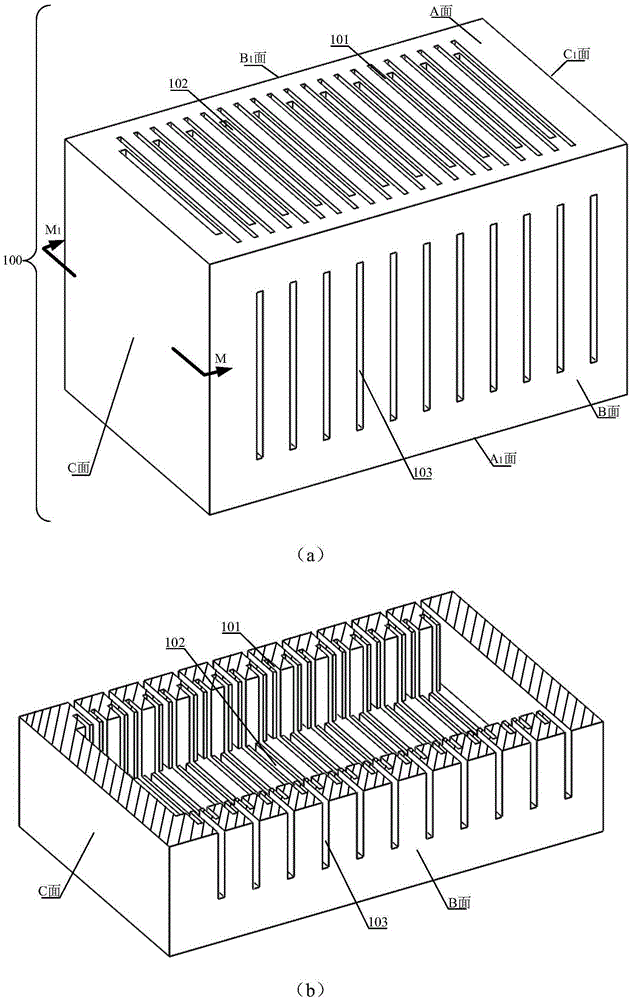

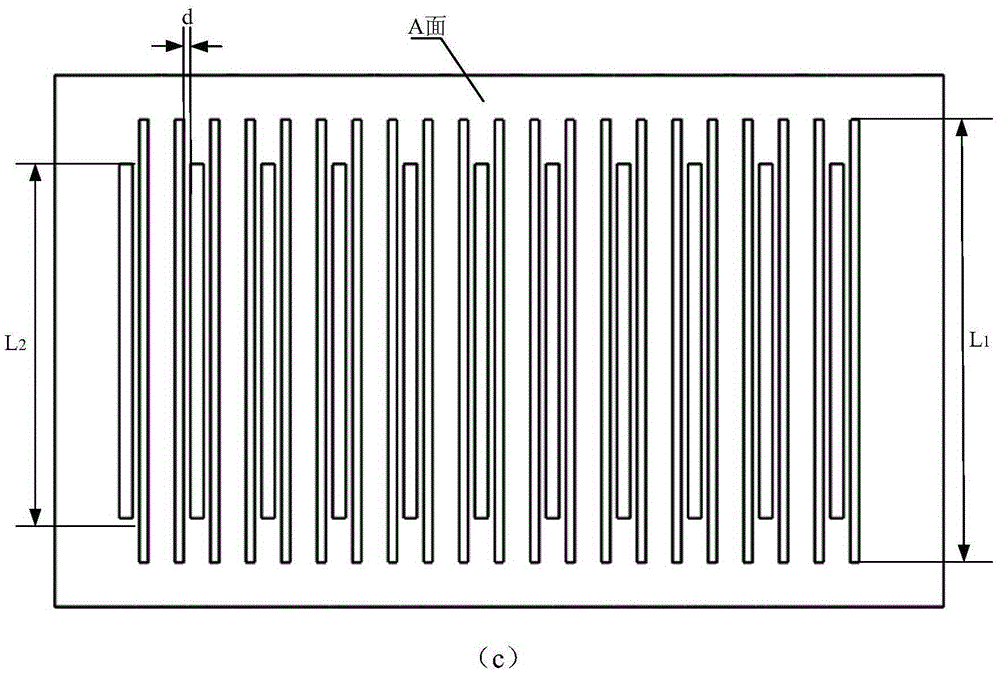

[0039] Wherein, the battery frame 100 is made of polytetrafluoroethylene insulating and corrosion-resistant material, and its dimensions are: 800 mm in length, 500 mm in width, and 500 mm in height. The opposite sides A-A of the battery frame 100 1 There are 100 pairs of straight-through empty slots 101 for accommodating the isolation windows 200, and the 100 isolation windows 200 are arranged and inserted into the straight-through empty slots 101 of the battery frame 1...

Embodiment 2

[0051] In this embodiment, the isolation window 200 includes a "back" type window 205 and a bipolar isolation layer located in the hollow between two "back" type windows 205, wherein the bipolar isolation layer is composed of the isolation layer 201 and The porous positive electrode current collecting layer 202 and the porous negative electrode current collecting layer 203 located on both sides of the isolation layer 201 and in close contact with the isolation layer 201 are composed.

[0052] Wherein, the isolation layer 201 is an electronic insulating layer that isolates the positive and negative current collector layers and prevents the electrons in the battery from freely passing through, while the lithium ions in the electrolyte or gel electrolyte can freely pass through, and its thickness is 0.2mm. Both the porous positive electrode current collecting layer 202 and the porous negative electrode current collecting layer 203 are ion / electron mixed conductive layers through w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com