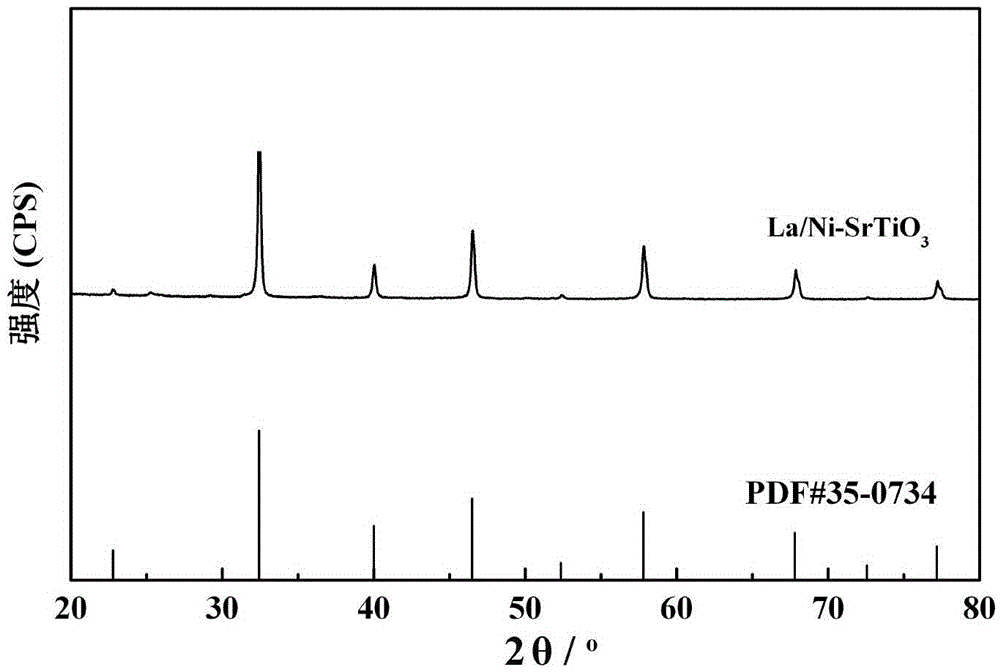

Preparation method of visible-light response nano La/Ni-SrTiO3

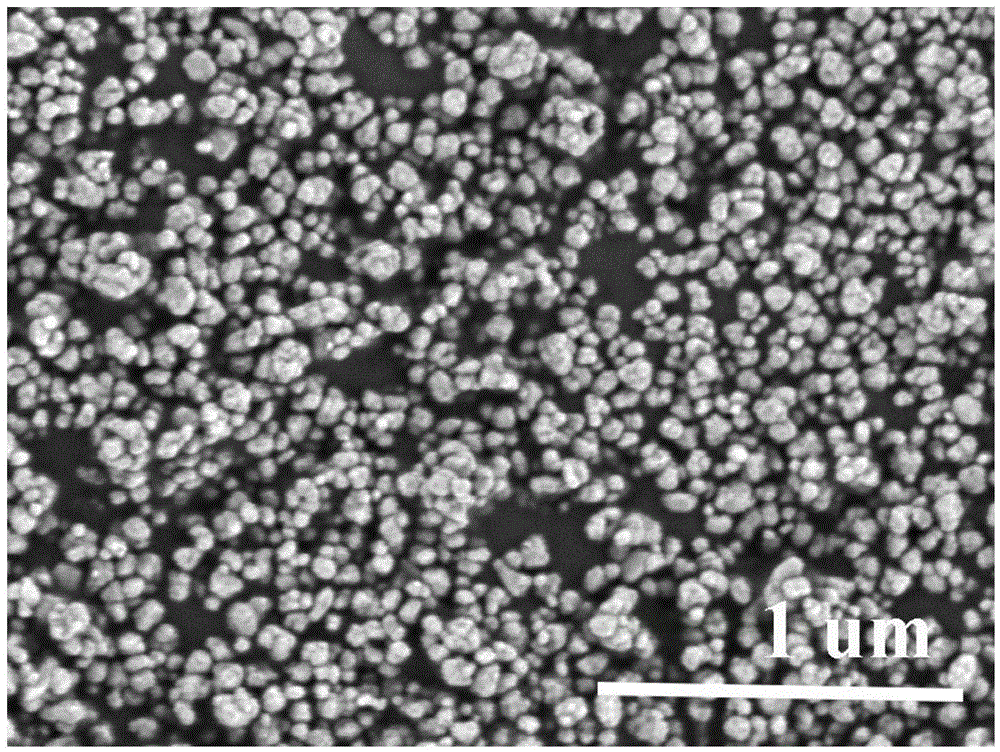

A visible light and nanotechnology, applied in the direction of nanotechnology, nanotechnology, and nanotechnology for materials and surface science, can solve problems such as insignificant response to visible light, easy aggregation of particles, and complicated preparation technology of strontium titanate. The effect of uniform shape and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) 0.01mol strontium nitrate (mass is 2.12g), 0.086g lanthanum nitrate, 0.058g nickel nitrate were dissolved in 4.3mL water, and stirred at room temperature on a magnetic stirrer for 30min to obtain strontium nitrate-lanthanum nitrate-nickel nitrate - A mixed solution of water. Dissolve 0.025 mol of citric acid in 5 mL of deionized water, and stir for 30 min at room temperature on a magnetic stirrer to prepare an aqueous solution of citric acid. Mix the obtained strontium nitrate-lanthanum nitrate-nickel nitrate aqueous solution and citric acid aqueous solution, and stir on a magnetic stirrer at room temperature for 30 min, and record it as liquid A. Dissolve 0.01 mol of butyl titanate in 10.2 mL of ethylene glycol, and stir for 30 min at room temperature on a magnetic stirrer, and record it as liquid B.

[0025] (2) After raising the temperature of liquid A obtained in step (1) to 55°C, drop liquid B into liquid A at a constant speed, and stir while adding to prevent...

Embodiment 2、 example 3

[0032] Dissolve 0.086g of lanthanum nitrate in step (1) in Example 1 in 4.3mL of deionized water and change it to 0.0645g and 0.1075g respectively.

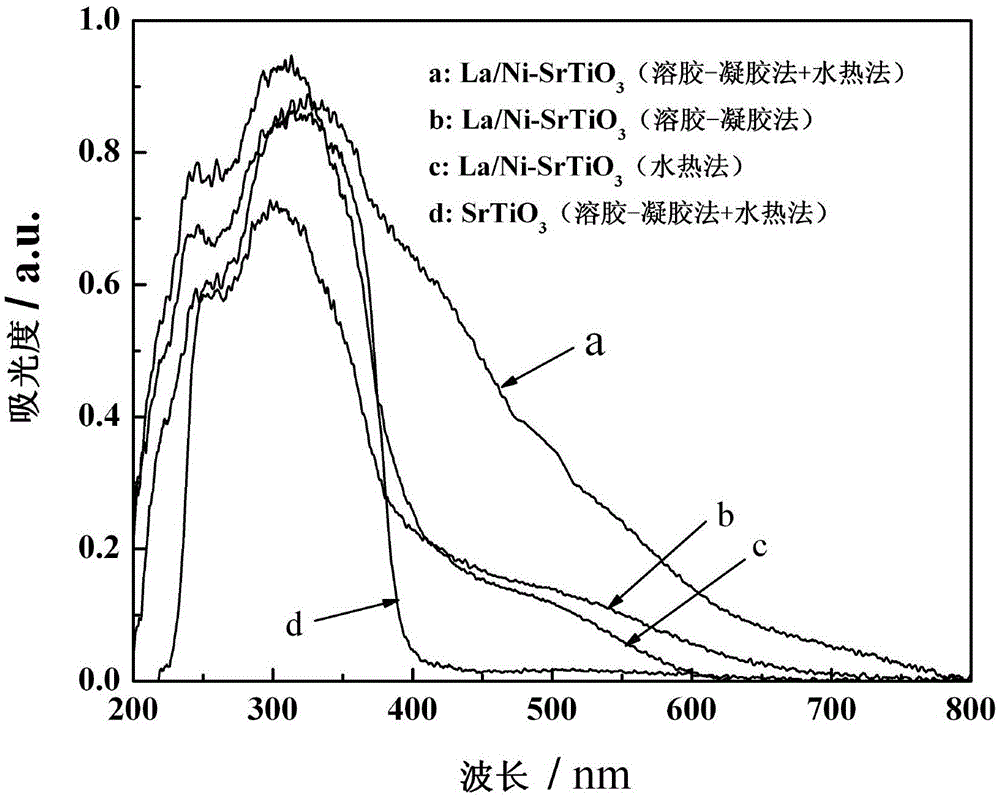

Embodiment 4、 example 5

[0034] Dissolve 0.086g of lanthanum nitrate in step (1) in Example 1 in 4.3mL of deionized water, and change it to 0.043g and 0.129g respectively (equivalent to containing 0.01g and 0.03g of lanthanum nitrate in every milliliter of water), and all other operations are Same as Example 1, the product obtained is obviously worse than Example 1 to the degree of absorption of visible light, which shows that the concentration of lanthanum nitrate has a great influence on product performance. Hours will also have an adverse effect on product performance, so when the concentration of lanthanum nitrate meets the solution of 0.015-0.025g lanthanum nitrate per milliliter of deionized water in this solution, the product obtained has the best absorption performance for visible light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com