Nano titanium dioxide photocatalyst with double-particle size distribution and preparation method thereof

A technology of nano-titanium dioxide and photocatalyst, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., to achieve good application effects, prevent corrosion and hazards, and achieve mild preparation conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

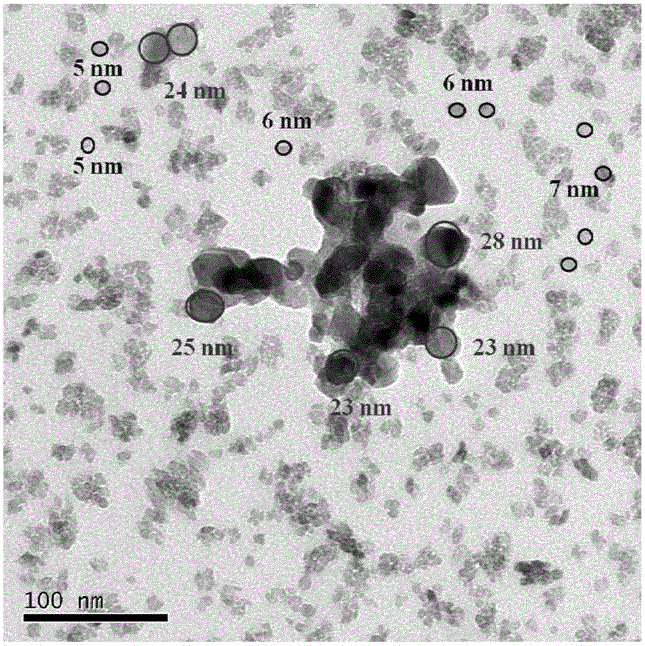

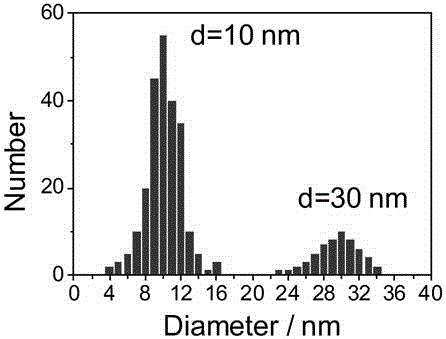

[0025] Add 100g of tetrabutyl titanate and 100g of ethanol into the reactor and stir evenly, control the temperature at 50°C, and slowly add 1g of polyacrylic acid, 1g of polyvinylpyrrolidone, and 500g of water at a stirring speed of 500-1000 rpm. Solution, the mass ratio of tetratitanate titanate: ethanol: polyacrylic acid: polyvinylpyrrolidone: water = 100:100:1:1:500 in the system; a transparent sol was formed after stirring at a constant temperature for 3 hours, and then 30g of commercial nano-titanium dioxide P25 was added, Start ultrasonic stirring and continue for 1h to form a transparent colloid; the obtained colloid adopts a conventional pressure spray drying device to prepare a nano-titanium dioxide photocatalyst with a double particle size distribution at a pressure of 1MPa and a hot air of 250°C, such as figure 1 As shown, the average diameter of small particles is 6nm, and the average diameter of large particles is 25nm.

[0026]Application effect: Take 10g of the...

Embodiment 2

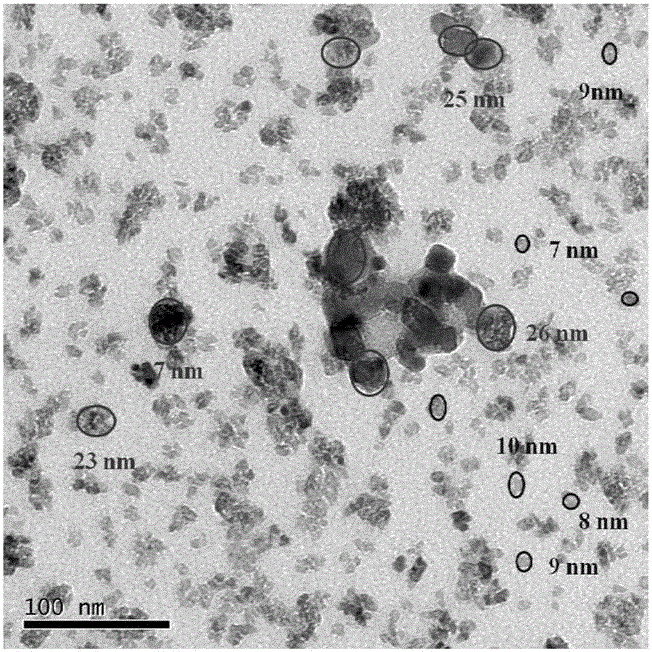

[0028] Add 100g tetraisopropyl titanate and 400g propanol into the reactor and stir evenly, control the temperature at 30°C, and slowly add 10g polyacrylic acid, 0.1g polyvinylpyrrolidone, 400g under the condition of stirring speed 500-1000 rpm A mixed solution of water, the mass ratio of tetratitanate: ethanol: polyacrylic acid: polyvinylpyrrolidone: water = 100:400:10:0.1:400 in the system; a transparent sol is formed after stirring at a constant temperature for 5 hours, and then 10g of commercial nano Titanium dioxide P25, start ultrasonic stirring, and continue for 3 hours to form a transparent colloid; the obtained colloid adopts a conventional pressure spray drying device to prepare a nano-titanium dioxide photocatalyst with a double particle size distribution at a pressure of 5 MPa and a hot air of 200 ° C, such as figure 2 As shown, the small particle diameter is 8nm on average, and the large particle diameter is 28nm on average.

[0029] Application effect: Take 50g ...

Embodiment 3

[0031] Add 100g of tetrabutyl titanate and 800g of ethanol into the reactor and stir evenly, control the temperature at 40°C, and slowly add 10g of polyacrylic acid, 1g of polyvinylpyrrolidone, and 100g of water under the condition of a stirring speed of 500-1000 rpm. Solution, the mass ratio of titanate tetraester in the system: ethanol: polyacrylic acid: polyvinylpyrrolidone: water = 100:800:10:1:100; a transparent sol was formed after stirring at a constant temperature for 2 hours, and then 50g of commercial nano-titanium dioxide P25 was added, Start ultrasonic stirring and continue for 1 hour to form a translucent colloid; the obtained colloid is prepared using a conventional pressure spray drying device at a pressure of 10 MPa and hot air at 150°C to prepare a nano-titanium dioxide photocatalyst with a double particle size distribution. result with figure 1 Similarly, the average size of the small particles is 6 nm and the average size of the large particles is 26 nm.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com