Production method of propylene

A propylene and catalyst technology, applied in the field of methanol conversion to produce propylene, can solve the problem of reducing the selectivity of olefins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Add 1260 grams of water, 78.4 grams of sodium hydroxide, 168 grams of ethylenediamine, 103.7 grams of aluminum sulfate and 700 grams of silica sol into the beaker in a certain order, stir and age at room temperature for 1 hour, and then change the temperature in the crystallization kettle at 160-190 °C After 2 days of crystallization, ZSM-5 / ZSM-35 mixed crystal raw powder with a silicon-aluminum ratio of 30 was obtained.

[0044] 20 grams of ZSM-5 / ZSM-35 mixed crystal molecular sieves washed, dried and roasted after crystallization were placed in 400 milliliters of 5% NH by weight 4 NO 3 In the solution, exchange at a temperature of 85-90°C for 2 hours, and repeat 3 times. After the exchange, the ammonium type ZSM-5 / ZSM-35 mixed crystal molecular sieve is obtained by washing and drying. 10 grams of ammonium-type ZSM-5 / ZSM-35 mixed crystal molecular sieves were added with 3 grams of 40% silica sol as a binder, and extruded. After drying at 120°C and calcining at 550°C...

Embodiment 2-3

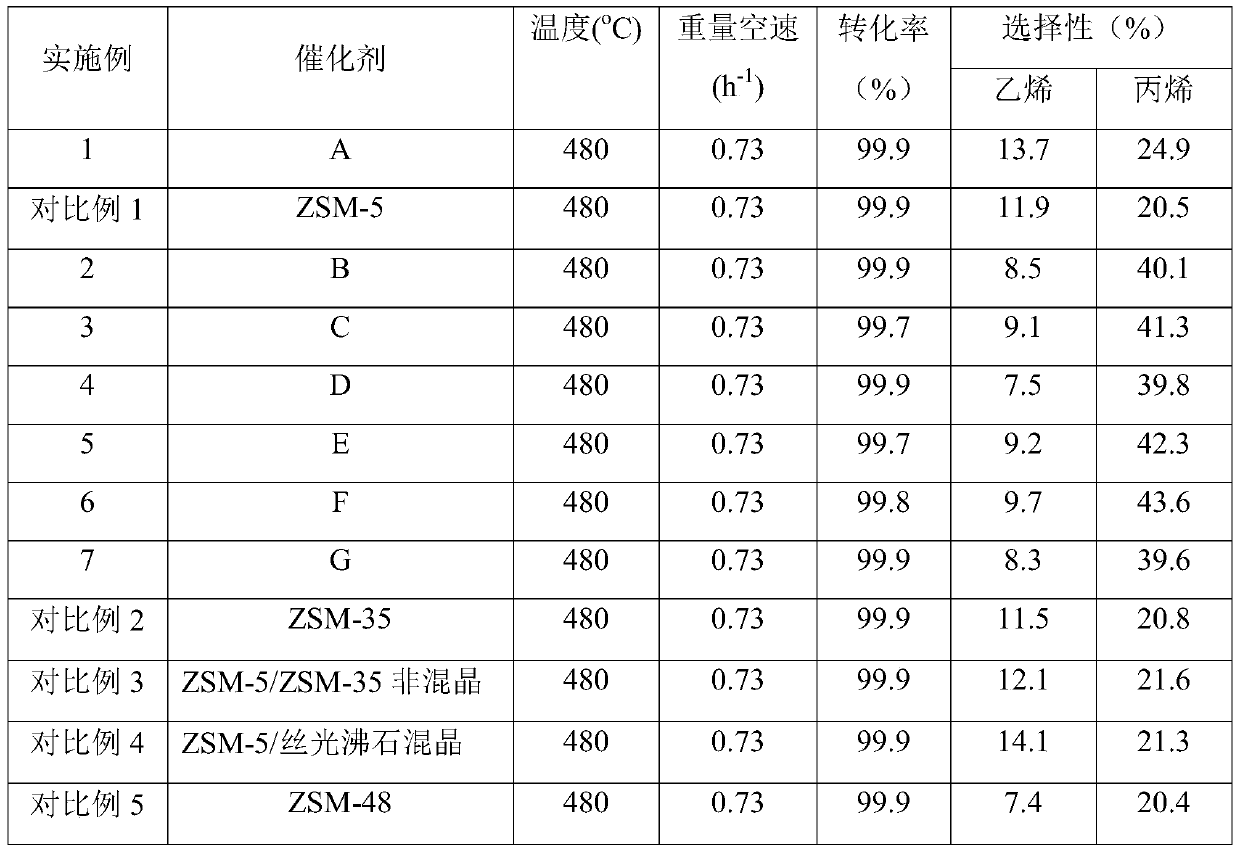

[0050] Changing the SiO of ZSM-5 / ZSM-35 Mixed Crystal 2 / Al 2 o 3 Ratio, synthesize ZSM-5 / ZSM-35 mixed crystal former powder according to the method identical with embodiment 1, moulding, make catalyst B (SiO 2 / Al 2 o 3 =100) and Catalyst C (SiO 2 / Al 2 o 3 =200), and evaluated under the same conditions, the reaction results are shown in Table 1.

Embodiment 4-7

[0052] The catalyst numbered A is impregnated and modified with diammonium hydrogen phosphate solution, so that the phosphorus content is 0.1-0.5% (weight fraction). After immersing at room temperature for several hours, rise to 60°C for vacuum drying, and bake at 550°C for 4 hours to obtain catalyst D (phosphorus content 0.2%), catalyst E (phosphorus content 0.4%), catalyst F (phosphorus content 0.6%) and catalyst G (phosphorus content 0.8%). All phosphorus-containing catalysts were in-situ treated with 100% steam for 48 h before feeding into the reaction. The reactivity of the catalyst is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com