Catalyst components used for olefin polymerization, preparation method and application thereof, catalyst used for olefin polymerization and application thereof

An olefin polymerization and catalyst technology, which is applied to catalyst components and their application fields in olefin polymerization, can solve the problems of the difficulty of small particle size carriers and the poor regularity of large particle size carriers, and achieves improved repeatability, good Stereospecificity, effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

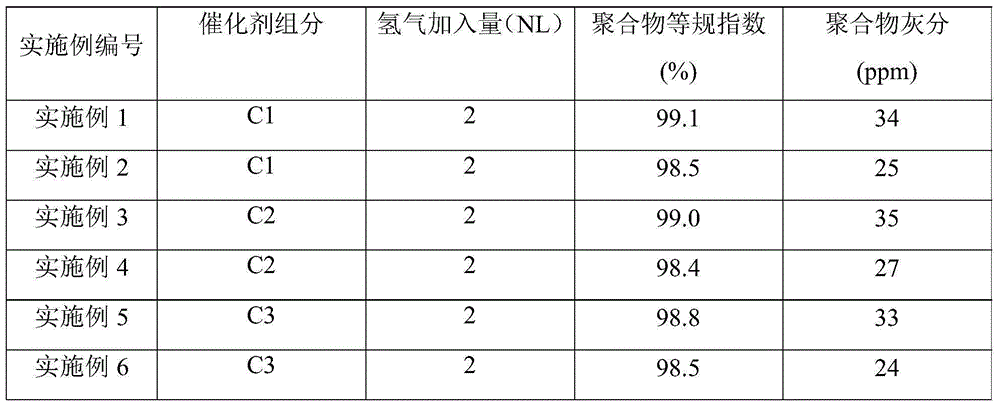

Examples

preparation example Construction

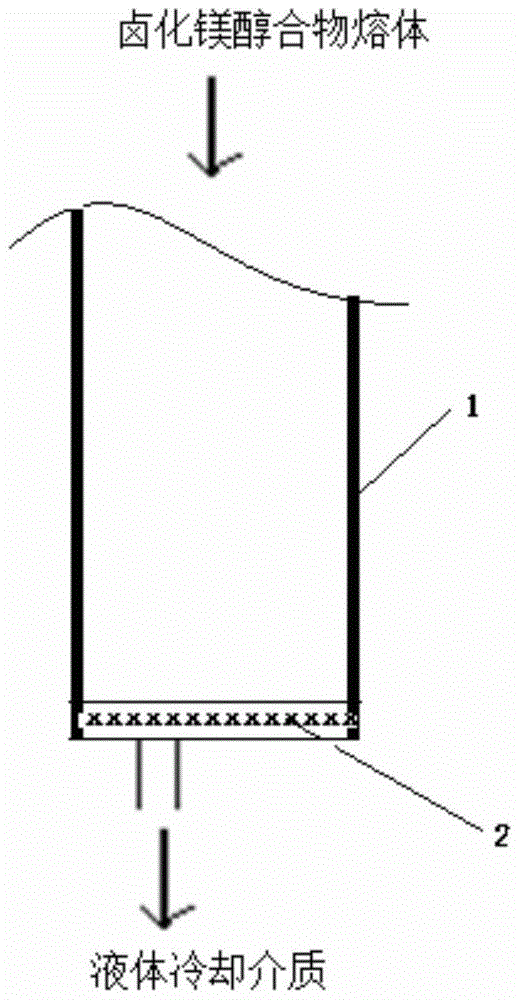

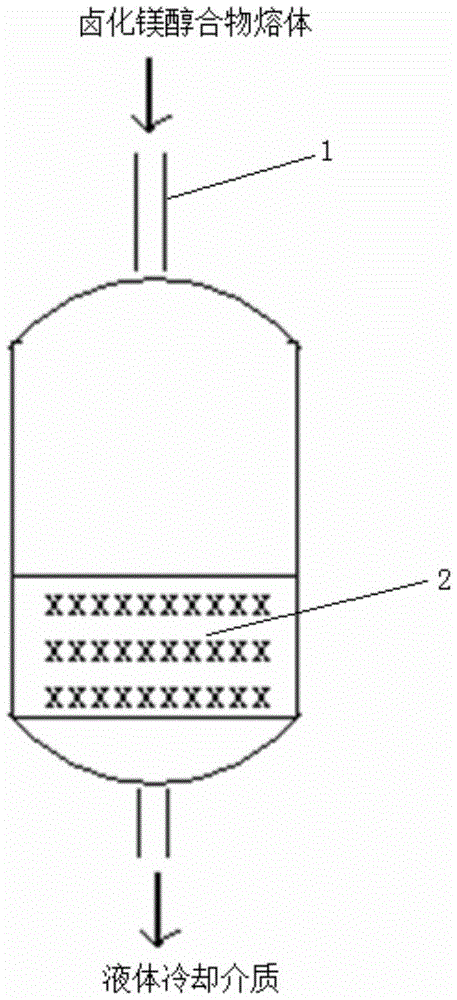

[0046] As mentioned above, the present invention provides a method for preparing a catalyst component for olefin polymerization, the method comprising: carrying out a contact reaction with a magnesium halide alcoholate carrier, a titanium compound and an internal electron donor, the internal donor The electron body contains an internal electron donor compound a, an internal electron donor compound b and an internal electron donor compound c, the internal electron donor compound a is a glycol ester compound, and the internal electron donor compound b is a diether compound , the internal electron donor compound c is a monocarboxylic acid ester; the preparation step of the magnesium halide alcoholate carrier includes: under pressure, the magnesium halide alcoholate melt passes through the structural unit with holes and the liquid Cooling medium contact.

[0047] According to the method of the present invention, preferably, the pressurizing conditions include: the pressure is 0.05...

Embodiment approach

[0053] According to a preferred embodiment of the present invention, the structural unit with holes is a mesh layer.

[0054] According to the method of the present invention, the adduct solid particles with equivalent particle morphology can be obtained by adopting the metal mesh with multi-layer large-aperture structure and the metal mesh with relatively small number of layers with small-aperture structure. When preparing small particle size (such as less than 30 μm) adduct carrier, it is preferable to use a metal mesh structure with 1-20 layers of small pore structure (such as pore size of 30-50 μm). It is preferred to use a metal mesh structure with 1-20 layers of relatively large aperture (eg, 65-200 μm aperture) structure.

[0055] According to a preferred embodiment of the present invention, the mesh layer includes 1-20 layers, preferably 2-8 layers; the thickness of each layer is 0.01-0.35mm, preferably 0.05-0.25mm, more preferably 0.1-0.15mm mm.

[0056] According t...

preparation Embodiment 1

[0154] In a 1L autoclave, add 500ml of silicone oil, 30g of magnesium chloride, and 50ml of ethanol, raise the temperature to 125°C with stirring, and stir at 125°C for 3 hours. The metal mesh (each layer thickness 0.1mm) is directly placed in 3L hexane pre-cooled to -30°C, the liquid is filtered off, the solid is washed three times with hexane, and dried in vacuum to obtain 50 grams of spherical magnesium chloride alcoholate solid particles S1, the alcohol / magnesium molar ratio is 2.6, and the characterization results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com