Flexible fiber having flame retardancy and preparation method thereof

A flexible fiber and flame retardant technology, applied in the field of flexible fibers with flame retardant properties and their preparation, can solve the problems of strong flammability and low strength of cellulose fibers, and achieve soft texture, increased flame retardant effect, and improved technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

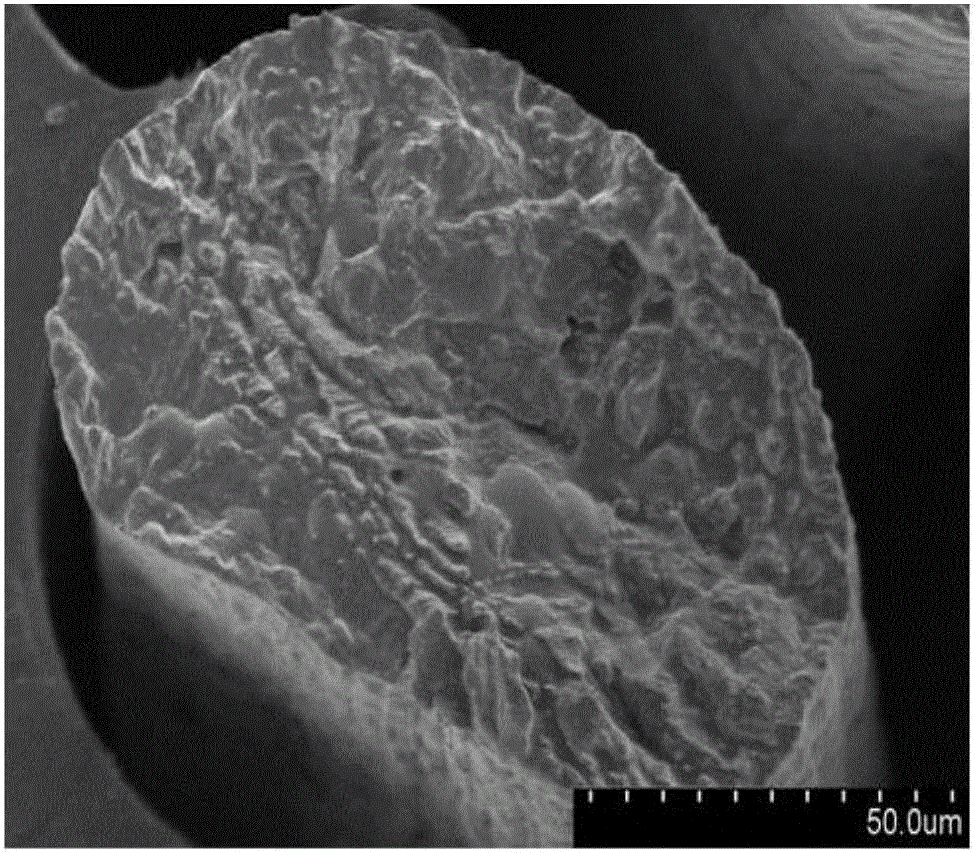

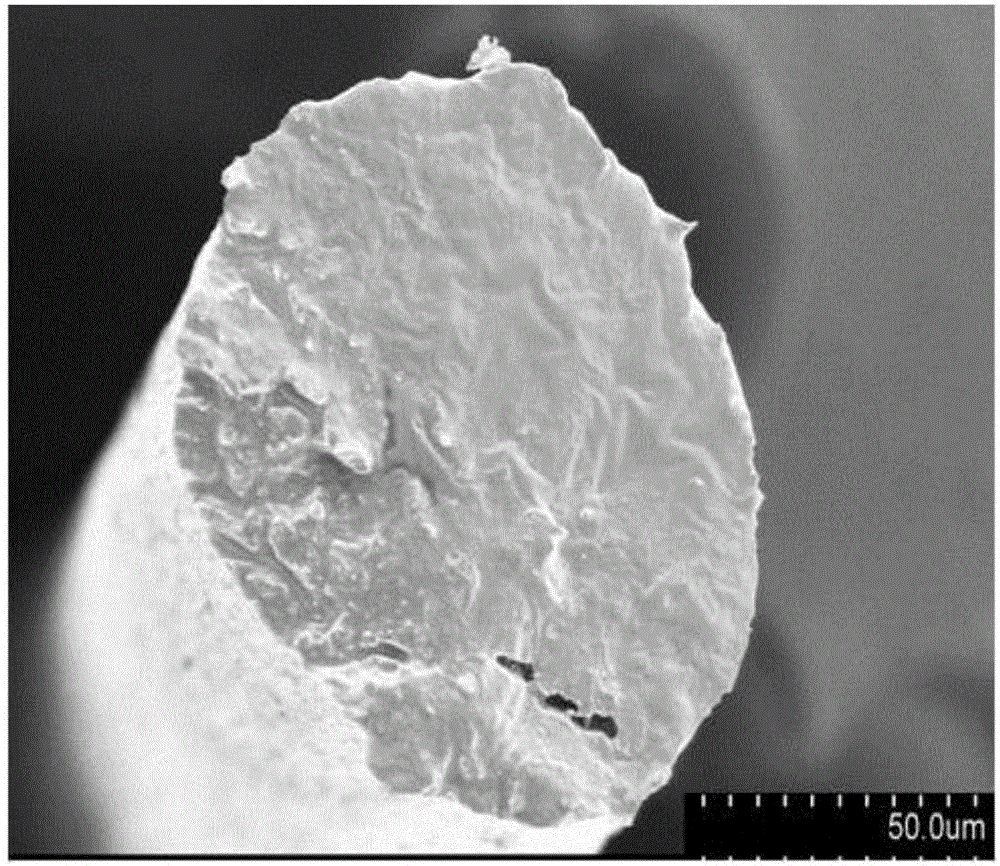

Image

Examples

Embodiment 1

[0046] 2.0 g of cellulose pulp board (DP: 800) was pulverized into flakes, then placed in an electric blast drying oven, and dried at 100° C. for 24 hours until the moisture content was 0.5%.

[0047] Add the pretreated cellulose paddle to the prepared 18g ionic liquid, which is composed of [BMIM]Ac, alkyl quaternary ammonium salt, and DMSO in a weight ratio of 1:3:7. ionic liquid;

[0048] Under the condition of heating and stirring, the dissolution reaction occurs. The heating and stirring environment is as follows: the stirring rate is 250 rpm, the oil bath temperature is 65°C, and the stirring time is 2h.

[0049] Add 1.8 g of amino silicone oil to the obtained pure cellulose solution, and continue the dissolution reaction under the environment of heating and stirring. The heating and stirring environment at this time is as follows: the stirring rate is 350 rpm, the oil bath temperature is 68° C., and the stirring time is 3 hours.

[0050]The prepared blended spinning s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com