A plastic car stop device with imitation stone effect

A stone-like and plastic-like technology, which is applied in road safety devices, roads, buildings, etc., can solve problems such as hard to see the car bumper, health hazards of processing workers, vehicle collision and scratches, etc., and achieve good stone-like effect and visual experience Outstanding, easy to transport and install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

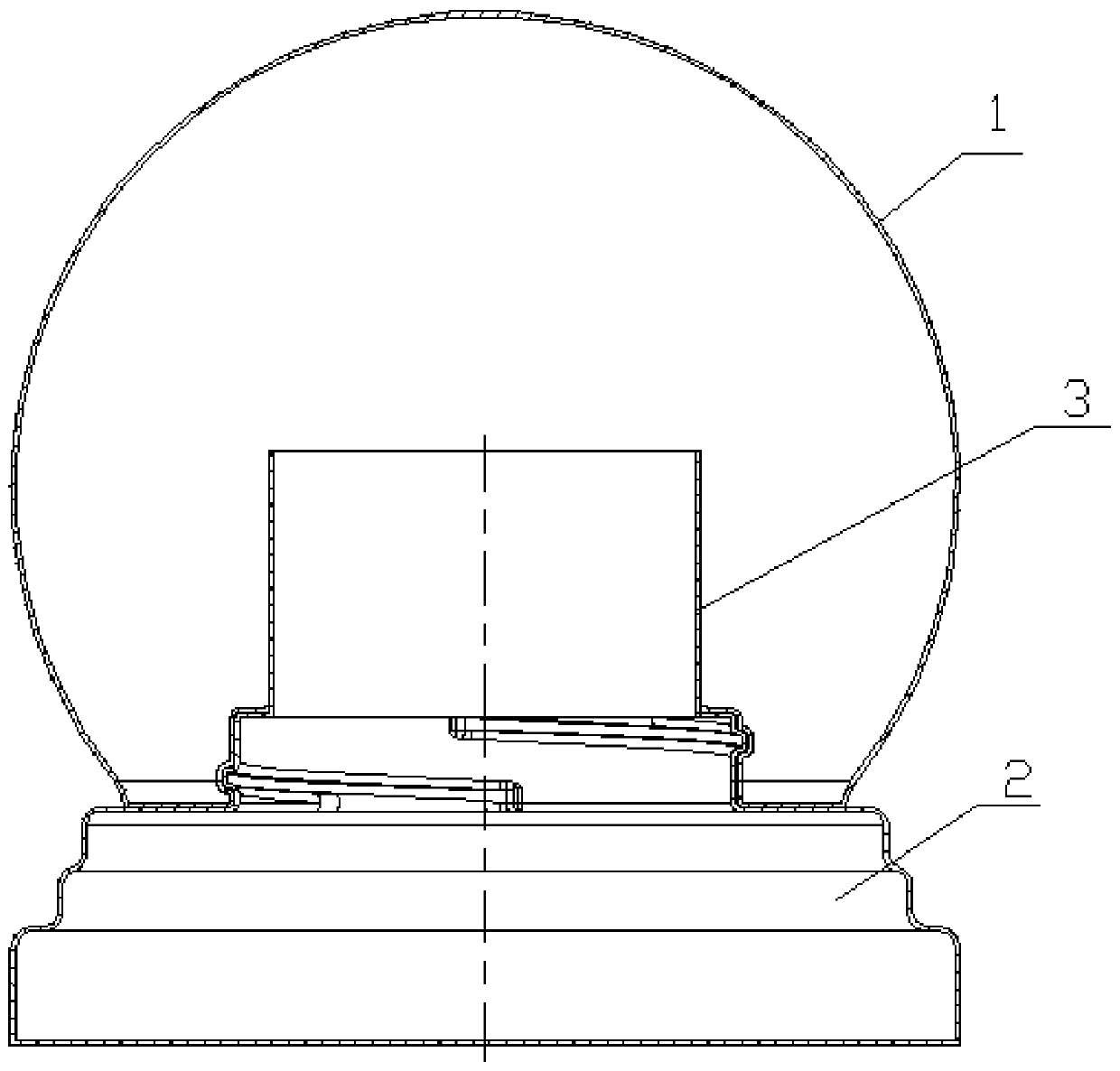

[0042] Such as figure 1 The shown plastic car stop device with imitation stone effect includes a hollow base and a spherical shell 1 placed on the base. The base is composed of a base 2 and a convex tube 3 on the base. The outer wall of the bottom of the convex tube is An external thread (single thread) is provided, and an internal thread is provided on the inner wall of the bottom of the spherical shell, and the spherical shell is screwed with the convex pipe.

[0043] Both the base and the shell are made of polyethylene powder with stone-like effect through rotational molding process, specifically: polyethylene powder, including 78.6Kg of natural color powder, 20Kg of white powder, 1Kg of black powder, and 0.1 kg of light gray powder Kg, dark gray powder 0.1Kg, red powder 0.2Kg, mixed on a medium-speed mixer for 5 minutes, took 4Kg and put it into the rotomolding mold, at an oven temperature of 260°C, heating time 25 minutes, spindle speed 4rpm, sub-shaft speed 5rpm, cooling...

Embodiment 2

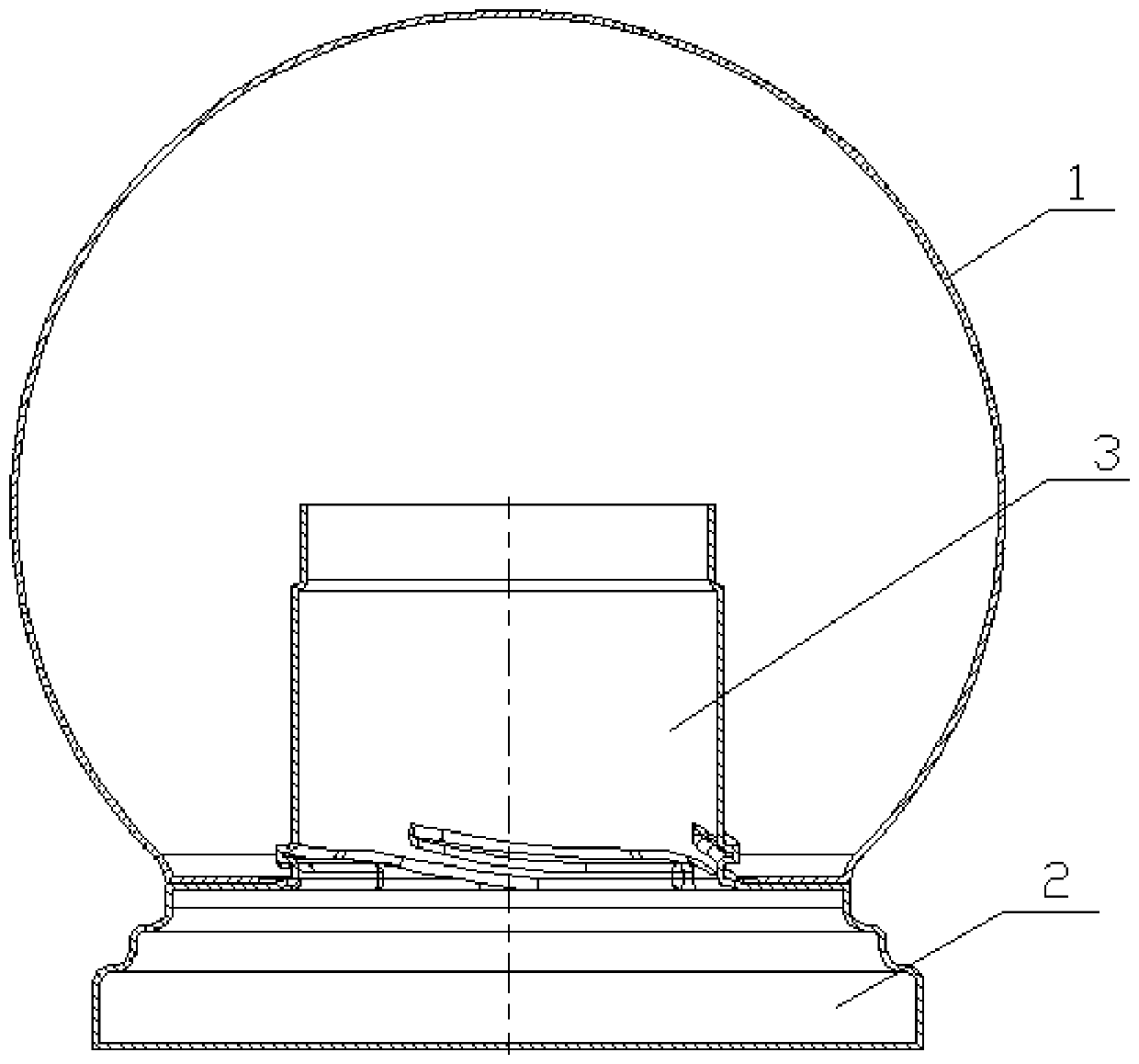

[0045] Such as figure 2 The shown plastic car stop device with imitation stone effect includes a hollow base and a spherical shell 1 placed on the base. The base is composed of a base 2 and a convex tube 3 on the base. The outer wall of the bottom of the convex tube is An external thread (double thread) is provided, and an internal thread is provided on the inner wall of the bottom of the spherical shell, and the spherical shell is screwed with the convex pipe.

[0046] Both the base and the shell are made of polyethylene powder with a stone-like effect through a rotational molding process, specifically: polyethylene powder, including 70.6Kg of natural color powder, 24Kg of white powder, 5Kg of black powder, and 0.1 kg of light gray powder Kg, dark gray powder 0.1Kg, red powder 0.2Kg, mixed on a medium-speed mixer for 5 minutes, took 4Kg and put it into the rotomolding mold, at an oven temperature of 260°C, heating time 25 minutes, spindle speed 4rpm, sub-shaft speed 5rpm, co...

Embodiment 3

[0048] Such as figure 1 The shown plastic car stop device with imitation stone effect includes a hollow base and a spherical shell placed on the base. The base is composed of a bottom platform and a convex tube on the bottom platform. Screw thread (single thread), the inner wall of the bottom of the spherical shell is provided with internal thread, and the spherical shell is screwed with the convex pipe.

[0049] Both the base and the shell are made of polyethylene powder with stone-like effect through rotational molding process, specifically: polyethylene powder, including 58Kg of natural color powder, 5Kg of white powder, 20Kg of black powder, 5Kg of light gray powder, Dark gray powder 10Kg, red powder 2Kg, mixed on a medium-speed mixer for 5 minutes, took 4Kg and put it into the rotomolding mold, under the process conditions of oven temperature 260°C, heating time 25 minutes, spindle speed 4rpm, sub-shaft speed 5rpm, cooling time 30min Perform rotational molding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com