Hygienic insecticide microcapsules and preparation method thereof

A technology of insecticides and microcapsules, which is applied in the field of microcapsules of pyrethroid hygienic insecticides, can solve the problems of endangering human physical and mental health, increasing the cost of prevention and control, and large skin irritation, so as to reduce skin irritation and save prevention and treatment Excellent cost and long-lasting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

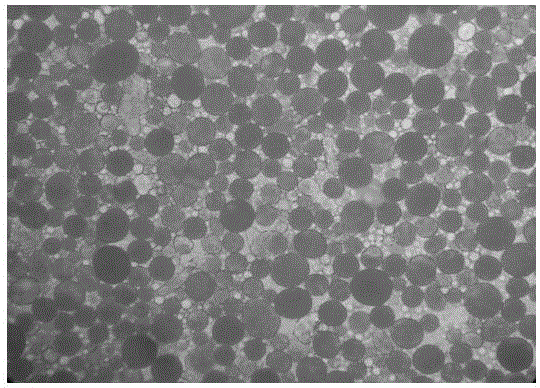

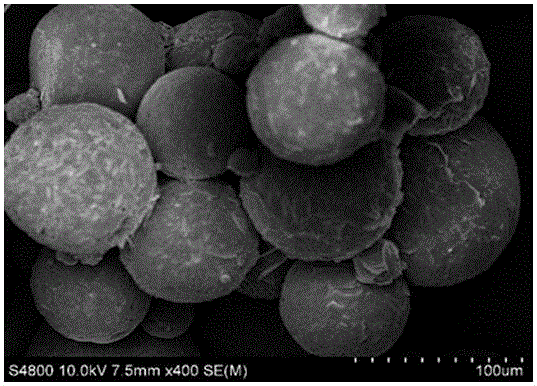

Image

Examples

Embodiment 1

[0033] 1) Weigh 0.30 g of the original drug of tetramethrin and put it into 7.50 g of ethyl acetate, stir until the original drug is completely dissolved, then add 0.15 g of ethyl cellulose into the solution, stir until the ethyl cellulose is completely dissolved, and make amine-containing Clear Solution A of Pyrethrin and Ethylcellulose.

[0034] 2) Weigh 22.20 g of deionized water into a beaker, add 0.15 g of emulsifier, and then magnetically stir until the emulsifier is completely dissolved to prepare a transparent solution B containing emulsifier.

[0035] 3) Mix the transparent solution A obtained in step 1) with the transparent solution B obtained in step 2), and cut at high speed (15000 rpm) with a high-speed shear for 1 min to obtain an emulsion.

[0036] 4) Remove ethyl acetate from the emulsion obtained in step 3) by a rotary evaporator at 40 °C to obtain a suspension containing microspheres.

[0037] 5) The microsphere-containing suspension obtained in step 4) is f...

Embodiment 2

[0039] 1) Weigh 0.30 g of beta-cypermethrin and put it into 9.00 g of dichloromethane, stir until the original medicine is completely dissolved, then add 0.30 g of ethyl cellulose into the solution, stir until the ethyl cellulose is completely dissolved, and make beta-cypermethrin and a clear solution A of ethyl cellulose.

[0040] 2) Weigh 19.80 g of deionized water into a beaker, add 0.90 g of emulsifier, and then magnetically stir until the emulsifier is completely dissolved to prepare a transparent solution B containing emulsifier.

[0041] 3) Mix the transparent solution A obtained in step 1) with the transparent solution B obtained in step 2), and cut it with a high-speed shearer at high speed (10000 rpm) for 1 min to obtain an emulsion.

[0042] 4) The emulsion obtained in step 3) was removed by a rotary evaporator at 20 °C to obtain a suspension containing microspheres.

[0043] 5) The microsphere-containing suspension obtained in step 4) is filtered, washed with deio...

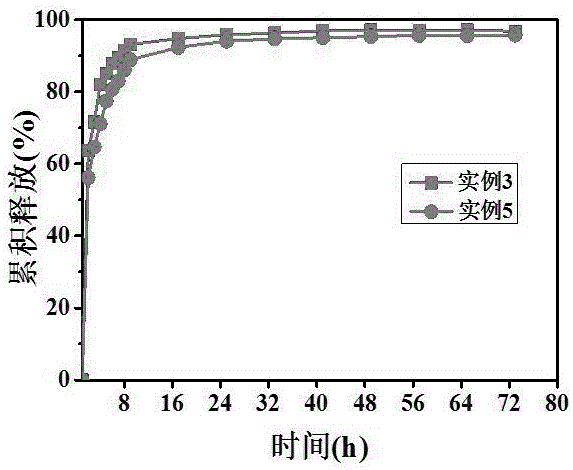

Embodiment 3

[0045] 1) Weigh 0.30 g of lambda-cyhalothrin technical material into 10.50 g of dichloromethane, stir until the technical material is completely dissolved, then add 0.45 g of ethyl cellulose into the solution, stir until the ethyl cellulose is completely dissolved, and prepare A clear solution A containing lambda-cyhalothrin and ethylcellulose was obtained.

[0046] 2) Weigh 17.25 g of deionized water into a beaker, add 1.80 g of emulsifier, and then magnetically stir until the emulsifier is completely dissolved to prepare a transparent solution B containing emulsifier.

[0047] 3) Mix the transparent solution A obtained in step 1) and the transparent solution B obtained in step 2), and cut at high speed (15000 rpm) with a high-speed shear for 1 min to obtain an emulsion.

[0048] 4) The emulsion obtained in step 3) was removed by a rotary evaporator at 40 °C to obtain a suspension containing microspheres.

[0049] 5) The microsphere-containing suspension obtained in step 4) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com