Vitamin A and derivative thereof-loaded cyclodextrin-metal organic framework complex and deep processing method of vitamin A and derivative thereof

A metal-organic framework and cyclodextrin technology, which can be used in drug combinations, active ingredients of hydroxyl compounds, inactive ingredients of polymer compounds, etc., can solve problems such as unfavorable packaging, storage and transportation, and achieve uniform, controllable and safe particle size. High performance and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Preparation of acidified CD-MOFs-VAP composites with different particle sizes

[0067] Dissolve 3.26g of γ-CD and 1.12g of KOH in 100mL of water, pre-add 60mL of methanol to the mixed solution of γ-CD and KOH, seal it, and heat it at 50°C for 2h. After reacting for a certain period of time, 1.28g of polyethylene glycol 20000 was added, and after standing at room temperature for a period of time, it was washed with ethanol and dichloromethane, and the obtained crystals were vacuum-dried to obtain basic micron-sized CD-MOFs (average particle size 1~ 10 μm), the pH is about 11-13, and the yield is about 80%.

[0068] Dissolve 3.26g of γ-CD and 1.12g of KOH in 100mL of water, pre-add 60mL of methanol to the mixed solution of γ-CD and KOH, seal it, and heat at 50°C for 2h. After reacting for a certain period of time, add an equal volume of methanol, and then add 1.28g of polyethylene glycol 20000. After standing at room temperature for a period of time, wash with ethanol an...

Embodiment 2

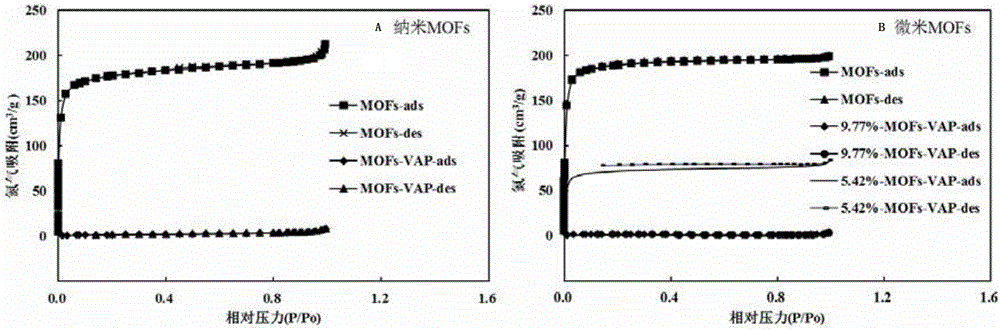

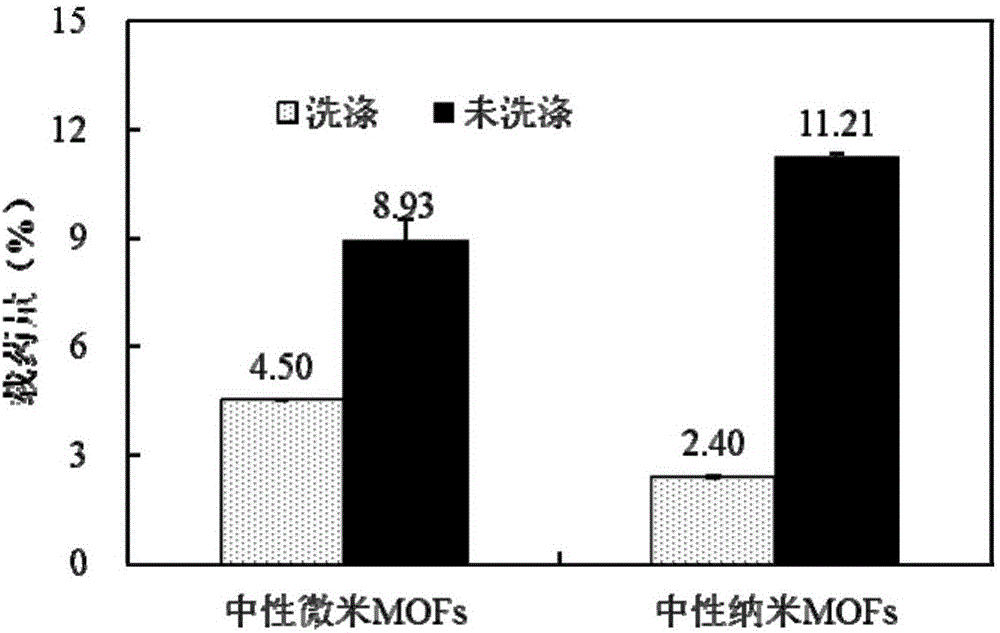

[0075] Specific surface area investigation of acidified CD-MOFs-VAP composites with different particle sizes

[0076] According to the method of Example 1, the mass ratio of CD-MOFs and vitamin A palmitate was adjusted to prepare respectively: acidified nanoscale CD-MOFs, unwashed acidified nanoscale CD-MOFs-VAP composite (VAP content is 14.11 wt%), acidified micron-sized CD-MOFs, unwashed acidified micron-sized CD-MOFs-VAP composite (VAP content of 9.77wt%) and unwashed acidified micron-sized CD-MOFs-VAP composite (VAP content of 5.42 wt%).

[0077] Carry out gas adsorption test on the above six samples respectively. The specific test process is: weigh 100-200mg of the sample to be tested, degas the sample at 50°C for 4-5h before gas adsorption, and measure the CD- MOF vs. N 2 Adsorption effect. The gas adsorption results are as figure 2 as shown, figure 2 It is the gas adsorption curve of acidified CD-MOFs before and after drug loading provided by Example 2 of the pre...

Embodiment 3

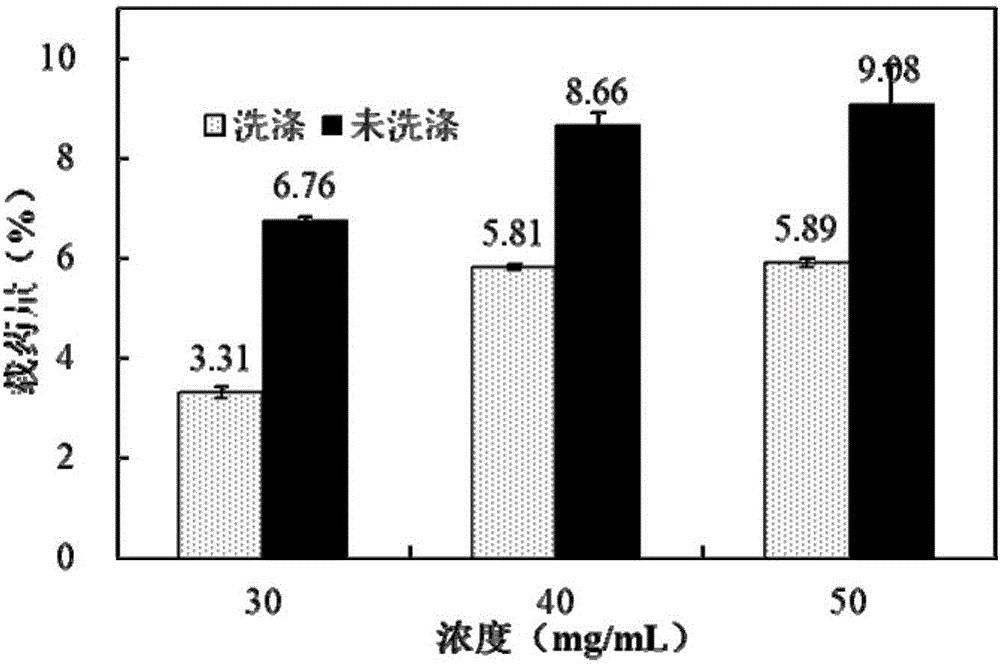

[0079] Preparation of acidified micron-sized CD-MOFs-VAP complexes at different dosage concentrations

[0080] Dissolve 3.26g of γ-CD and 1.12g of KOH in 100mL of water, pre-add 60mL of methanol to the mixed solution of γ-CD and KOH, seal it, and heat it at 50°C for 2h. After reacting for a certain period of time, 1.28g of polyethylene glycol 20000 was added, and after standing at room temperature for a period of time, it was washed with ethanol and dichloromethane, and the obtained crystals were vacuum-dried to obtain basic micron-sized CD-MOFs (average particle size 1~ 10 μm), the yield was about 80%.

[0081] Weigh a certain amount of basic micron-sized CD-MOFs prepared above, disperse them in absolute ethanol containing glacial acetic acid (the volume ratio of glacial acetic acid to absolute ethanol is 1:10), and place them in a shaker at 25 °C After shaking and incubating for 2 h, the solids were washed with ethanol and dried in vacuum to obtain acidified micron-sized CD...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com