A cleaning device and method for a hollow fiber gas separation membrane module

A gas separation membrane and cleaning device technology, applied in the field of separation membrane cleaning, can solve problems such as damage to the combination of the support layer and the functional layer, the breakage of the membrane filament at the junction of the membrane filament and the sealant, and the scrapping of the membrane module, so as to improve the cleaning effect and Efficiency, shortened cleaning time, and the effect of a thorough restoration of performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Use the method for cleaning the hollow fiber gas separation membrane module disclosed in the present invention to clean the polysulfone hollow fiber gas separation membrane module and test the initial performance of the membrane module. The stop frequency is 10 times / minute, and the flow rate of the disturbed airflow is 10 m 3 / h, disturbed air flow cleaning for 1 hour, positive and negative two-way pressure cleaning time is 1 hour, cleaning pressure is 0.1MPa, step temperature purge flow rate is 50m 3 / h, the purging temperature is 60, 80, 100°C, and the purging time is 2, 2, 1 hour respectively. Clean the three membrane modules of the same batch and similar pollution degree according to the above-mentioned specific operation process, which are modules 1-3 respectively. After the cleaning, the performance of the membrane modules is tested, and the results are shown in Table 1.

Embodiment 2

[0034] Use the method for cleaning the hollow fiber gas separation membrane module disclosed in the present invention to clean the polysulfone (PSF) hollow fiber gas separation membrane module and test the initial performance of the membrane module. The start-stop frequency of the medium airflow is 15 times / min, and the flow rate of the disturbed airflow is 20 m 3 / h, disturbed air flow cleaning for 2 hours, positive and negative two-way pressurized cleaning time is 1 hour, cleaning pressure is 0.1MPa, step temperature purge flow rate is 50m 3 / h, the purging temperature is 60, 80, 100 o C, the purging time is 2, 2, 1 hour respectively. Clean the three membrane modules of the same batch and similar pollution degree according to the above-mentioned specific operation process, which are modules 4-6 respectively. After the cleaning, the performance of the membrane modules is tested, and the results are shown in Table 1.

Embodiment 3

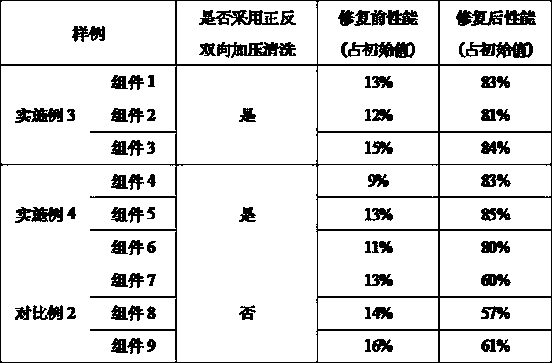

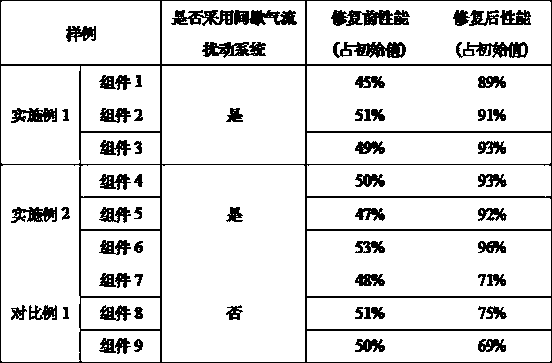

[0041] Use the method for cleaning the hollow fiber gas separation membrane module disclosed in the present invention to clean the polyimide hollow fiber gas separation membrane module and test the initial performance of the membrane module. The frequency of airflow start and stop is 10 times / min, and the flow rate of disturbed airflow is 15 m 3 / h, disturbed air flow cleaning for 1.5 hours, positive pressure cleaning time for 3 hours, reverse pressure cleaning time for 1 hour, cleaning pressure of 0.1MPa, step temperature purge flow rate of 70m 3 / h, the purging temperatures are 60, 90, and 120°C, and the purging times are 2, 1, and 2 hours, respectively. Three membrane modules (modules 1-3) of the same batch and with similar pollution levels were cleaned according to the above-mentioned specific operation process for parallel experiments. After cleaning, the performance of the membrane modules was tested. The results are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com