Magnetic porous cationic polymer adsorbent and preparation method thereof

A cationic and macromolecular technology, applied in the field of magnetic porous cationic macromolecular adhesive and its preparation, can solve the problems of poor adsorption effect, poor applicability, large dosage, etc., and achieve the effects of simple process, simplified time-consuming, and low-solvent preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

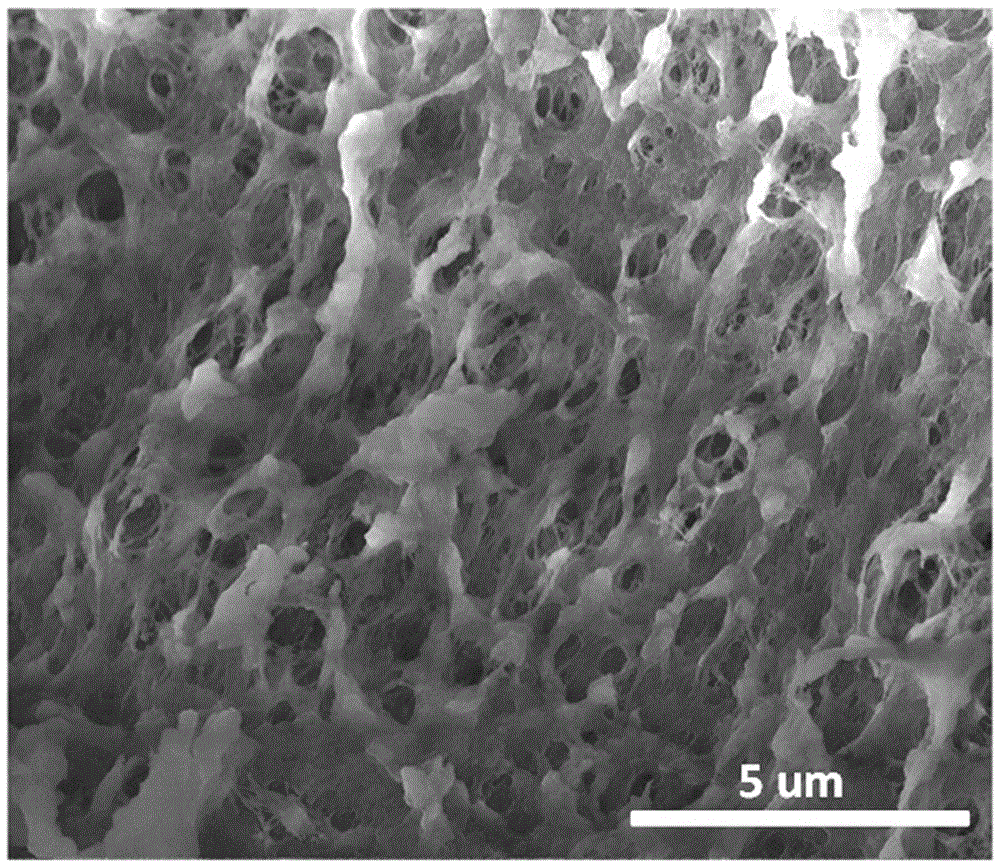

[0017] (1) Disperse 0.2 g of ferrous chloride tetrahydrate and 0.8 g of ferric chloride hexahydrate in 30 mL of deionized water, and mix well by ultrasonic;

[0018] (2) Add the mixed solution obtained in step (1) dropwise into 50 mL of acetic acid solution in which 0.5 g of chitosan and 0.1 g of polyethyleneimine were dissolved, and emulsify with a homogenizer for 15 min;

[0019] (3) Transfer the mixture obtained in step (2) into a three-necked flask, heat it to 40°C after blowing in nitrogen, add 3 mL of ammonia water, react for 0.5 h, then add 0.1 g of polyethyleneimine, and emulsify with a homogenizer 10 minutes;

[0020] (4) Add 0.1 mL of epichlorohydrin to the mixture obtained in step (3), and cross-link for 0.5 hours; stop the reaction with cold water, and adjust the pH to neutral with 1mol / L hydrochloric acid solution, and then freeze the product after separation with an external magnetic field Dry to obtain the magnetic porous cationic polymer adsorbent;

[0021] (...

Embodiment 2

[0023] (1) Disperse 0.5 g of ferrous chloride tetrahydrate and 2.5 g of ferric chloride hexahydrate in 30 mL of deionized water, and mix well by ultrasonic;

[0024] (2) Add the mixed solution obtained in step (1) dropwise into 50 mL of acetic acid solution in which 1.0 g of chitosan and 0.3 g of polyethyleneimine were dissolved, and emulsify with a homogenizer for 15 min;

[0025] (3) Transfer the mixture obtained in step (2) into a three-necked flask, heat it to 80°C after blowing in nitrogen, add 5.0 mL of ammonia water, react for 1.5 h, then add 0.8 g of polyethyleneimine, and emulsify with a homogenizer 10 minutes;

[0026] (4) Add 0.4 mL of epichlorohydrin to the mixture obtained in step (3), and conduct a crosslinking reaction for 1.0 hour; stop the reaction with cold water, and adjust the pH to neutral with 1mol / L hydrochloric acid solution, and freeze the product after separation with an external magnetic field Dry to obtain the magnetic porous cationic polymer adsor...

Embodiment 3

[0029] (1) Disperse 1.0 g of ferrous chloride tetrahydrate and 2.5 g of ferric chloride hexahydrate in 30 mL of deionized water, and mix well by ultrasonic;

[0030] (2) Add the mixed solution obtained in step (1) dropwise to 50 mL of acetic acid solution in which 1.2 g of chitosan and 1.0 g of polyethyleneimine were dissolved, and emulsify with a homogenizer for 15 min.

[0031] (3) Transfer the mixture obtained in step (2) into a three-necked flask, heat it to 90°C after blowing in nitrogen, add 11.0 mL of ammonia water, react for 1.0 h, then add 2.0 g of polyethyleneimine, and emulsify with a homogenizer 10 minutes;

[0032] (4) Add 1.0 mL of epichlorohydrin to the mixture obtained in step (3), and cross-link for 2.0 hours; stop the reaction with cold water, and adjust the pH to neutral with 1mol / L hydrochloric acid solution, and freeze the product after separation with an external magnetic field Dry to obtain the magnetic porous cationic polymer adsorbent;

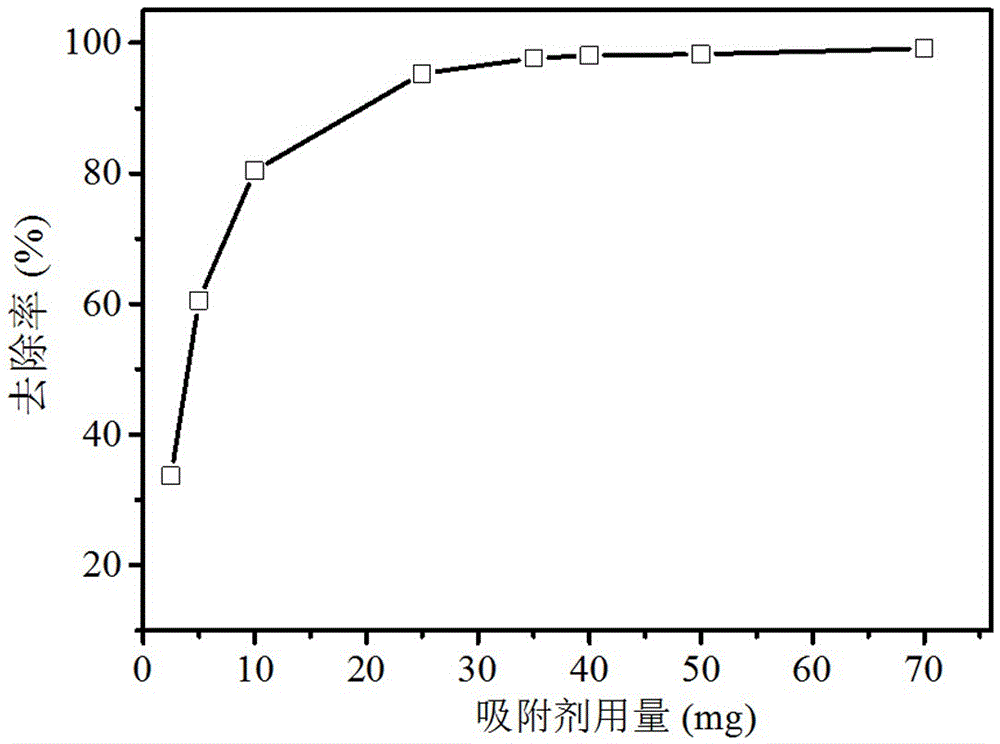

[0033] (5) 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com