Straw particle board and preparation method thereof

A particleboard and straw technology, applied in the field of straw particleboard and its preparation, can solve the problems of poor flexural strength and internal bonding strength, and achieve the effects of reduced production cost and good performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

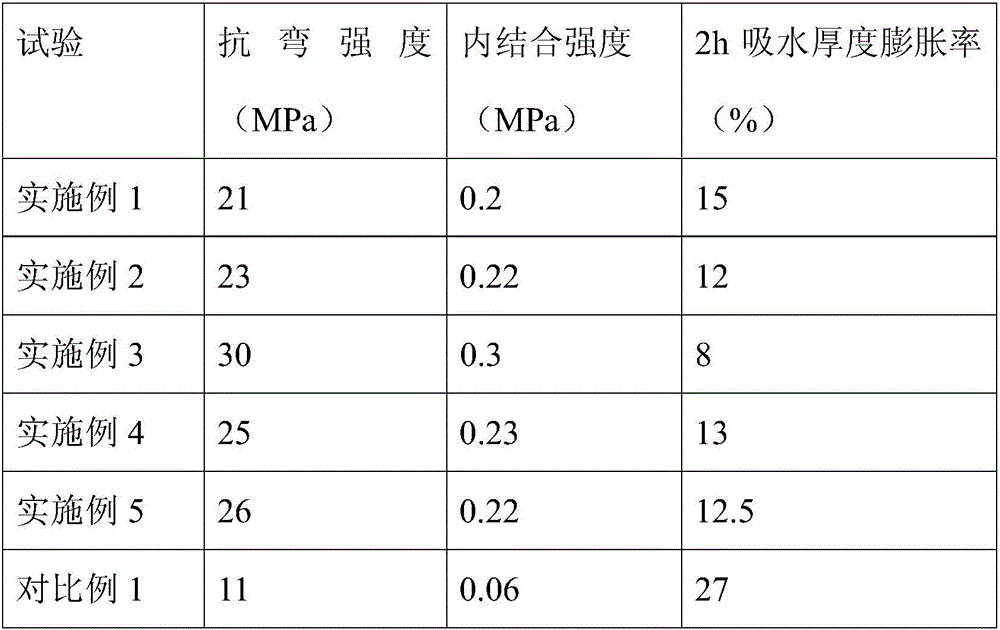

Examples

Embodiment 1

[0030] The preparation method of the present embodiment straw particleboard is carried out according to the following steps:

[0031] 1. Spray the mixed solution of phenolic adhesive or glue coupling agent evenly on the straw scrap until it is completely soaked, then cover it at room temperature for 2 hours, then put it in an oven, and dry it at 55-85°C until the moisture content is 10% to 14%, and then paved in the mold to form a slab;

[0032] 2. Cover the upper and lower surfaces of the slab with a steel plate, and then pre-press for 10 to 20 minutes under a pressure of 1 to 3 MPa;

[0033] 3. Dry the pre-pressed slab at 40°C to a moisture content of 5%;

[0034] 4. Evenly cover the surface of the dried slab with a layer of sodium lignosulfonate with a thickness of 1mm, absorb moisture in humid air with a humidity of 80% and a temperature of 65°C until the moisture content reaches 6%;

[0035] 5. Place cushion blocks between the upper and lower steel plates of the slab af...

Embodiment 2

[0045] The preparation method of the present embodiment straw particleboard is carried out according to the following steps:

[0046]1. Spray the mixed solution of phenolic adhesive or glue coupling agent evenly on the straw scrap until it is completely soaked, then cover it at room temperature for 2 hours, then put it in an oven, and dry it at 55-85°C until the moisture content is 10% to 14%, and then paved in the mold to form a slab;

[0047] 2. Cover the upper and lower surfaces of the slab with a steel plate, and then pre-press for 10 to 20 minutes under a pressure of 1 to 3 MPa;

[0048] 3. Dry the pre-pressed slab at 30°C to a moisture content of 2%;

[0049] 4. Evenly cover the surface of the dried slab with a layer of sodium lignosulfonate with a thickness of 3mm, absorb moisture in humid air with a humidity of 100% and a temperature of 60°C until the moisture content reaches 8%;

[0050] 5. Place cushion blocks between the upper and lower steel plates of the slab af...

Embodiment 3

[0054] The preparation method of the present embodiment straw particleboard is carried out according to the following steps:

[0055] 1. Spray the mixed solution of phenolic adhesive or glue coupling agent evenly on the straw scrap until it is completely soaked, then cover it at room temperature for 2 hours, then put it in an oven, and dry it at 55-85°C until the moisture content is 10% to 14%, and then paved in the mold to form a slab;

[0056] 2. Cover the upper and lower surfaces of the slab with a steel plate, and then pre-press for 10 to 20 minutes under a pressure of 1 to 3 MPa;

[0057] 3. Dry the pre-pressed slab at 35°C to a moisture content of 3.5%;

[0058] 4. Evenly cover the surface of the dried slab with a layer of sodium lignosulfonate with a thickness of 2mm, absorb moisture in humid air with a humidity of 100% and a temperature of 62°C until the moisture content reaches 8%;

[0059] 5. Place cushion blocks between the upper and lower steel plates of the slab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com