A multi-layer composite board processing device

A sheet metal processing, multi-layer composite technology, applied in the direction of lamination device, lamination, control lamination, etc., can solve the problems of affecting drying effect, high manufacturing cost, waste of energy, etc., to achieve short drying and curing time, manufacturing Low cost and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

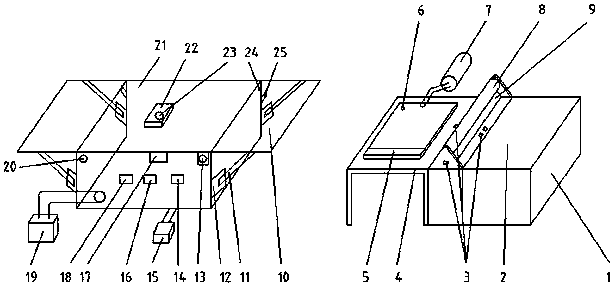

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

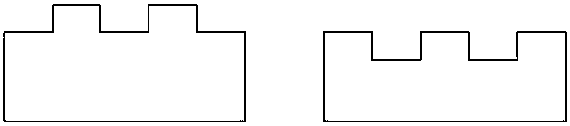

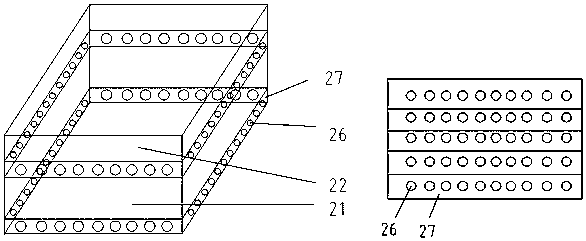

[0019] As shown in the figure, the first embodiment of the present invention is provided: a multi-layer composite plate processing device, including a placement frame 1, a bracket 4 and a furnace body 21, and the bracket 4 is placed on the placement frame 1 and the furnace body In the middle of 21, two squeeze wheels 8 and 9 are arranged on the placement frame 1, and the upper squeeze wheel 8 can move up and down. A travel switch 3 is provided, a double-layer insulation cotton bag 5 is arranged on the bracket 4, a pressure sensor 6 is arranged on the vacuum bag 5, the vacuum bag 5 is connected with the vacuum pump 7, and a relay 17 is arranged in the furnace body 21. The furnace body 21 is provided with a heating device 22 and an air duct 27, and several air outlets 26 are provided on the air duct 27, so that the heating is uniform, the power loss is small, energy sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com