Mechanical shot peening forming and strengthening method of fiber-metal super-hybrid composite laminated sheet

A technology of mechanical shot peening and shot peening, which is applied in the direction of chemical instruments and methods, lamination, control lamination, etc. It can solve the problems of high mold cost, failure to meet the manufacturing requirements and preparation of aerospace components, and achieve processing flexibility strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

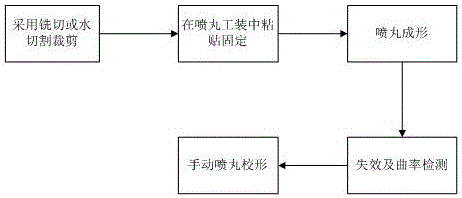

[0033] Example 1: Refer to the attached figure 1 The mechanical shot peening forming and strengthening method of a fiber-metal super-hybrid composite laminate shown includes the following steps:

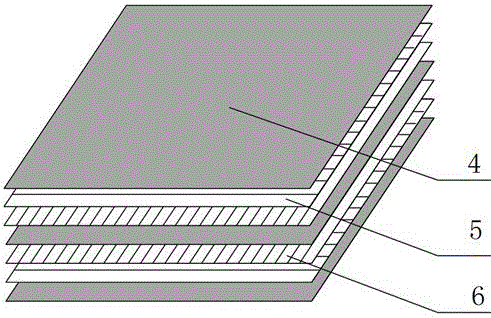

[0034] The first step is to select a 3 / 2 structure with a thickness of 1.5mm, such as image 3 As shown, the glass fiber-aluminum alloy super-hybrid composite material with a fiber layer direction of 0° / 90°, wherein the uppermost layer is the metal layer 4, the middle is the 0° fiber layer 5, and the bottom is the 90° fiber layer 6. The specific material The components are S4 high-strength glass fiber, epoxy resin, 2024 aluminum alloy;

[0035] The second step is to cut the material to 6000mm×1000mm by means of CNC milling. The specific milling process parameters are: rotation speed 14000r / min, feed speed 2m / min, back-cutting amount 0.1mm, tool diameter 1mm, Oil cooler;

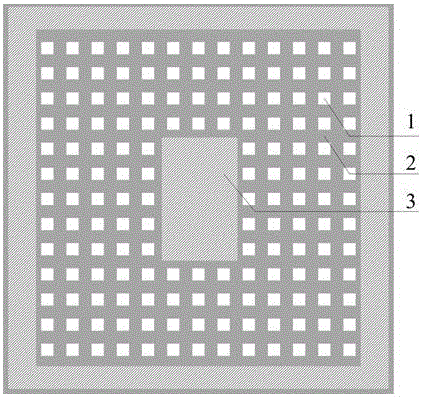

[0036] The third step is to fix the glass fiber-aluminum alloy super-hybrid composite material on the surface of the s...

Embodiment 2

[0042] The first step is to select a 5 / 4 structure with a thickness of 2.6mm and a carbon fiber-titanium alloy super-hybrid composite with a fiber layer direction of 0° / 0°. The specific material components are T700 carbon fiber, polyimide resin, and TC4 Aluminum alloy

[0043] The second step is to cut the material to 600mm×600mm by means of CNC milling. The specific process parameters are: rotation speed 10000r / min, feed speed 1m / min, back-cutting amount 0.1mm, tool diameter 2mm, water cooling;

[0044] The third step is to fix the carbon fiber-titanium alloy super-hybrid composite material on the surface of the supporting device by bonding and fixing;

[0045] The fourth step is to select AZB600 ceramic pellets, and perform single-sided shot peening on the material at a shot peening strength of 0.25A to obtain 80% shot peening coverage. The specific process parameters are: shot peening pressure 0.22MPa, flow rate 10Kg / min, distance 600mm, spray angle 90°, machine speed 505.5mm / mi...

Embodiment 3

[0048] The first step is to select a 2 / 1 structure with a thickness of 1.0mm and a carbon fiber-aluminum alloy hybrid composite with a fiber layer direction of 0° / 90° / 0°. The specific material components are T300 carbon fiber, polypropylene resin, and 7075 Aluminum alloy

[0049] The second step is to cut the material to 3000mm×900mm by means of CNC milling. The specific milling process parameters are: speed 16000r / min, feed speed 2m / min, back-cutting amount 0.05mm, tool diameter 05mm, Oil cooler;

[0050] The third step is to fix the carbon fiber-titanium alloy super-hybrid composite material on the surface of the supporting device by bonding and fixing;

[0051] The fourth step is to select AZB210 ceramic pellets, and perform double-sided shot peening and strengthening of the material at a shot peening strength of 0.105A, so that the material can obtain 100% shot peening coverage. The specific process parameters are: shot peening pressure 0.35MPa, flow rate 6Kg / min, distance 500m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com