A kind of ubenimex delta crystal form and preparation method thereof

A technology of ubenimex and crystal form, which is applied in chemical recovery, organic chemistry, separation/purification of carboxylic acid amides, etc., can solve the problems of long volatilization time and inability to meet the requirements of large-scale crystal form preparation, and reduce the cost of reagents and energy consumption, controllable production conditions and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

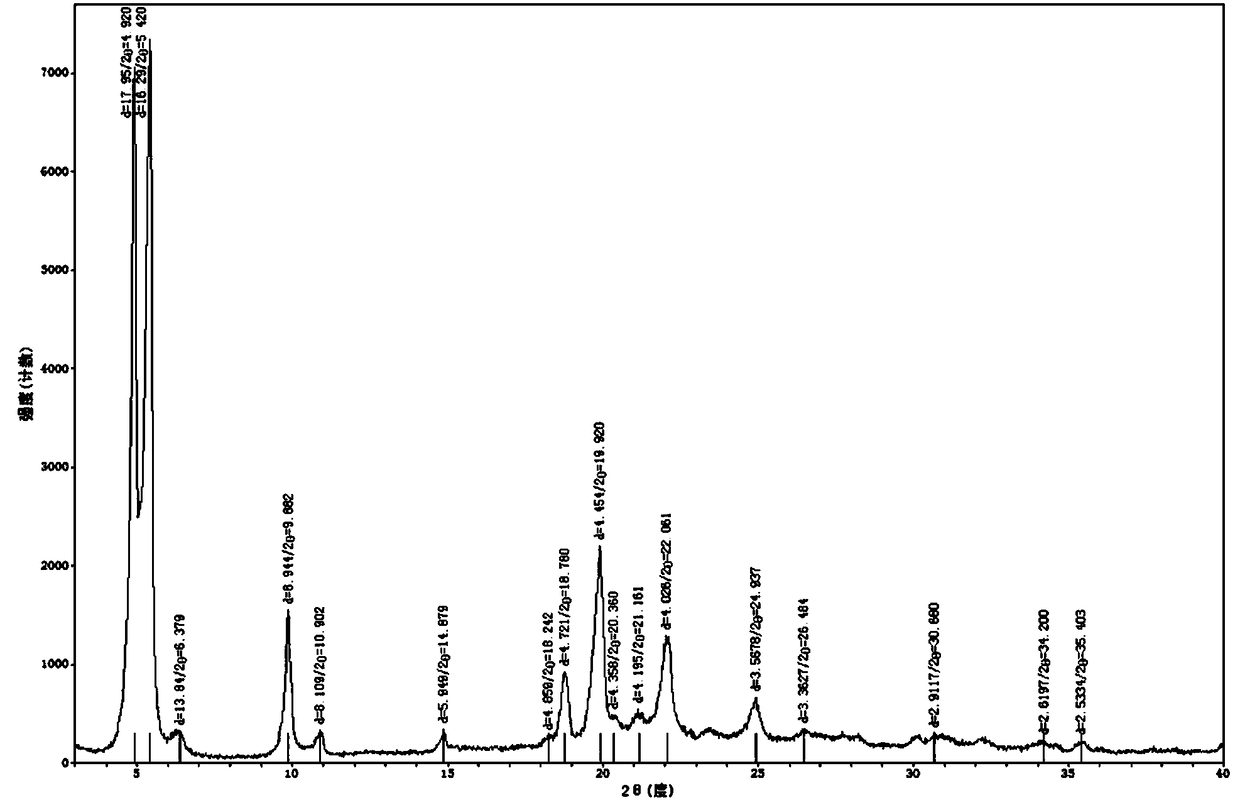

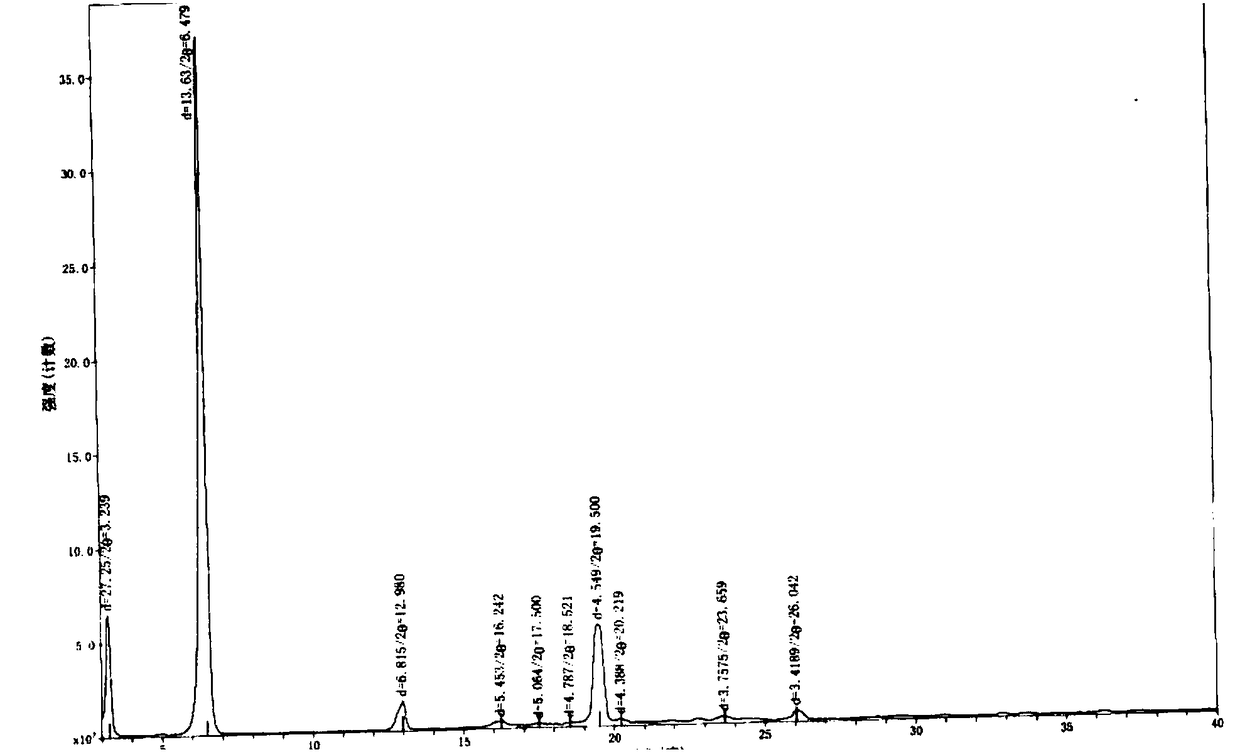

[0055] Example 1 Preparation of Ubenimex δ Crystal Form

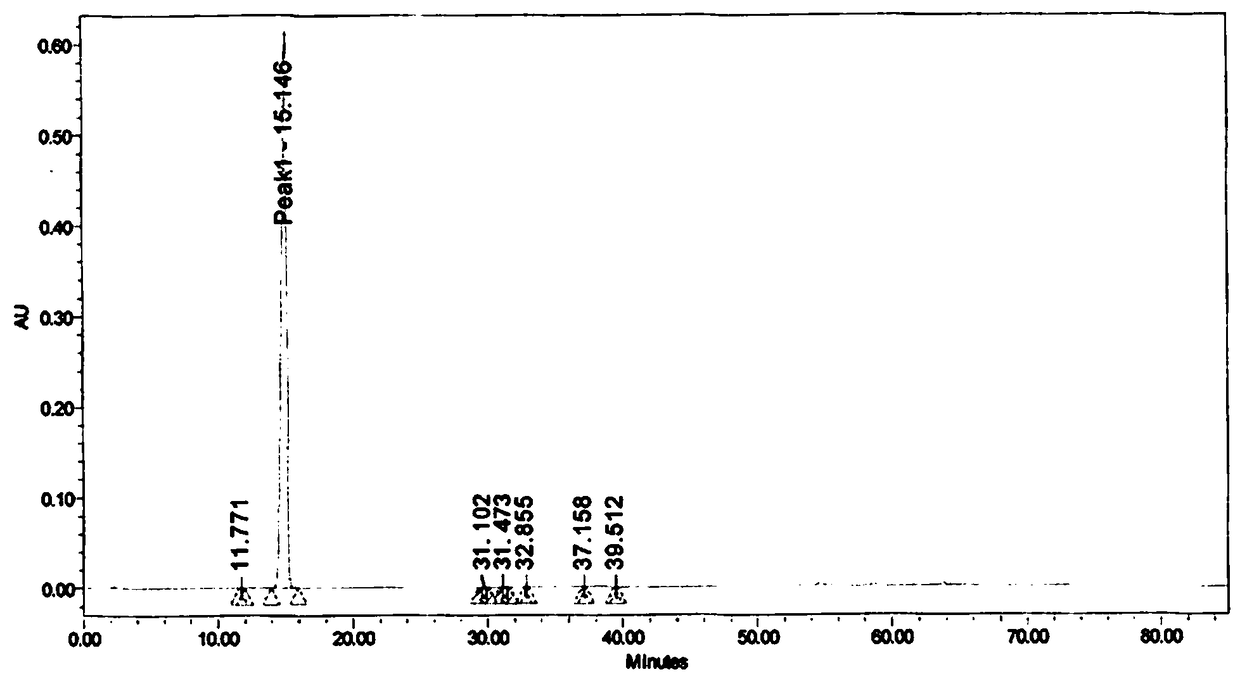

[0056] Dissolve 10g of ubenimex in a mixed solvent of 200ml of ethanol and 200ml of purified water at a temperature of 60°C. After the dissolution is complete, add 1.0g of activated carbon for decolorization at a temperature of 60°C; Stir at a speed of 1 / min to lower the temperature and crystallize, the crystallization temperature is 10°C, and the crystallization time is 3h; negative pressure suction filtration, put the filter cake in a vacuum oven at 70°C and dry for 8h to obtain 9.25g of white solid powder, with a yield of 92.5% , HPLC purity is 99.89%, total impurity 0.11%, maximum single impurity 0.06%. Its NMR results are:

[0057] 1 H NMR (400MHz, DMSO): δ7.30(s,5H),3.99(s,1H),3.89(s,1H),3.57(s,1H),2.92(m,2H),1.90(s,1H ),1.60(s,2H),0.85(d,J=4.7Hz,6H)

[0058] 13 C NMR (101MHz, DMSO): δ175.07(s, 1C), 171.48(s, 1C), 137.13(s, 1C), 129.50(s, 2C), 128.48(s, 2C), 126.64(s, 1C ),68.48(s,1C),55.20(s,1C),52.77(s,1C)...

Embodiment 2

[0065] Example 2: Preparation of Ubenimex δ Crystal Form

[0066] Dissolve 16g of Ubenimex in a mixed solvent of 320ml of ethanol and 160ml of purified water at a temperature of 60°C. After the dissolution is complete, add 1.28g of activated carbon to decolorize for 2 hours at a temperature of 50°C; Stir at min speed and lower the temperature for crystallization, the crystallization temperature is 15°C, and the crystallization time is 4h; negative pressure suction filtration, the filter cake is placed in a 75°C vacuum oven and dried for 16h to obtain 14.6g of white solid powder with a yield of 91.25%. The HPLC purity is 99.88%, the total impurity is 0.12%, and the maximum single impurity is 0.07%.

[0067] Its NMR data, DSC data, and powder diffraction data are basically consistent with the data of Example 1.

Embodiment 3

[0068] Example 3: Preparation of Ubenimex δ Crystal Form

[0069] Dissolve 10g of Ubenimex in a mixed solvent of 180ml of ethanol and 320ml of purified water at a temperature of 55°C. After the dissolution is complete, add 1.0g of activated carbon to decolorize for 2 hours at a temperature of 55°C; The temperature was 5°C, and the crystallization time was 3 hours; negative pressure suction filtration, and the filter cake was dried in a vacuum oven at 80°C for 4 hours to obtain 8.96 g of white solid powder, with a yield of 89.6%. The HPLC purity is 99.90%, the total impurity is 0.10%, and the maximum single impurity is 0.05%.

[0070] Its NMR data, DSC data, and powder diffraction data are basically consistent with the data of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com