Metal cross-linked acrylate emulsion and preparation method thereof

An acrylate and metal cross-linking technology, used in the field of architectural coatings, can solve the problems of unstable reaction and storage stability in the later stage, and achieve the effect of ensuring storage stability, excellent hardness and dense cross-linking density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

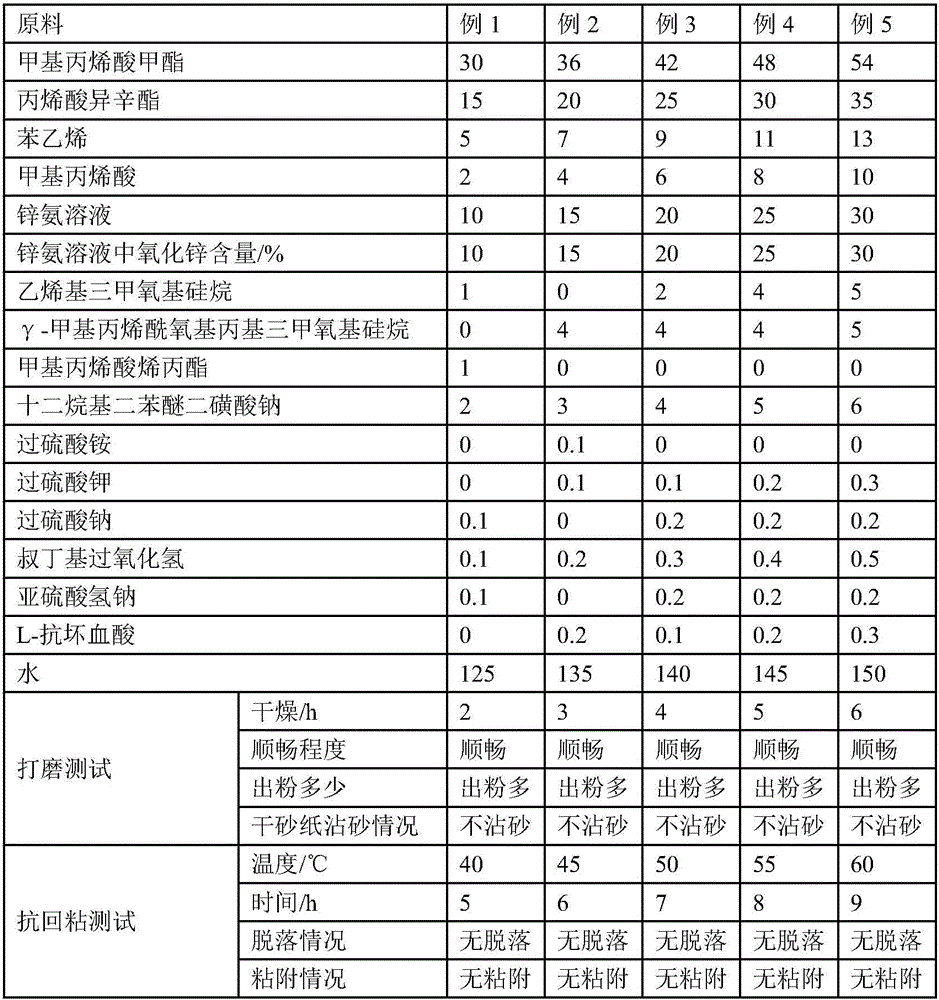

Examples

Embodiment 1

[0054] A kind of metal cross-linked acrylate emulsion is prepared by comprising the following steps carried out in sequence:

[0055] (1) Under normal temperature and pressure, add 1 part of sodium dodecyl diphenyl ether disulfonate and 20 parts of water into the emulsification tank, stir with a disperser for 5 minutes to make it fully mixed, and then add 30 parts of methacrylic acid in turn Methyl ester, 15 parts of isooctyl acrylate, 5 parts of styrene, 2 parts of methacrylic acid, 1 part of vinyltrimethoxysilane, 1 part of allyl methacrylate, use a disperser to stir for 20 minutes to make it fully mixed, That is, a pre-emulsion is made.

[0056] (2) Add 1 part of sodium dodecyl diphenyl ether disulfonate and 80 parts of water into a four-necked flask, heat up to 75°C, stir at 5-20r / min for 15 minutes, and dropwise add 1) The prepared pre-emulsion, 0.1 part of sodium persulfate dissolved in 5 parts of water, undergo polymerization reaction, the reaction temperature is 80 ° ...

Embodiment 2

[0065] A kind of metal cross-linked acrylate emulsion is prepared by comprising the following steps carried out in sequence:

[0066] (1) Under normal temperature and pressure, add 1 part of sodium dodecyl diphenyl ether disulfonate and 25 parts of water into the emulsification tank, stir for 5 minutes with a disperser to make it fully mixed, and then add 36 parts of methacrylic acid in turn Methyl ester, 20 parts of isooctyl acrylate, 7 parts of styrene, 4 parts of methacrylic acid, 4 parts of γ-methacryloxypropyltrimethoxysilane, stir for 20 minutes with a disperser to make it fully mixed, that is Make a pre-emulsion.

[0067] (2) Add 2 parts of sodium dodecyl diphenyl ether disulfonate and 75 parts of water into a four-necked flask, heat up to 79°C, stir at 5-20r / min for 20 minutes, and dropwise add 1) The prepared pre-emulsion, 0.2 parts of persulfate dissolved in 7 parts of water, carry out polymerization reaction, the reaction temperature is 83 ° C, the dropping time is...

Embodiment 3

[0077] A kind of metal cross-linked acrylate emulsion is prepared by comprising the following steps carried out in sequence:

[0078] (1) Under normal temperature and pressure, add 2 parts of sodium dodecyl diphenyl ether disulfonate and 30 parts of water into the emulsification tank, stir for 5 minutes with a disperser to make it fully mixed, and then add 42 parts of methacrylic acid in turn Methyl ester, 25 parts of isooctyl acrylate, 9 parts of styrene, 6 parts of methacrylic acid, 2 parts of vinyltrimethoxysilane, 4 parts of γ-methacryloxypropyltrimethoxysilane, using a disperser Stir for 20 minutes to make it fully mixed, that is, to make a pre-emulsion.

[0079] (2) Add 2 parts of sodium dodecyl diphenyl ether disulfonate and 70 parts of water into a four-necked flask, raise the temperature to 83°C, stir at a speed of 5-20r / min for 25 minutes, and simultaneously dropwise add 1) The prepared pre-emulsion, 0.3 parts of persulfate dissolved in 8 parts of water, undergo pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com