High permeability rate composite gas-permeable membrane and preparation method thereof

A breathable film and air permeability technology, applied in chemical instruments and methods, flat products, other household appliances, etc., can solve the problems of sultry heat, non-puncture resistance, and air permeability film powder falling off, and achieve high air permeability and tensile strength. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

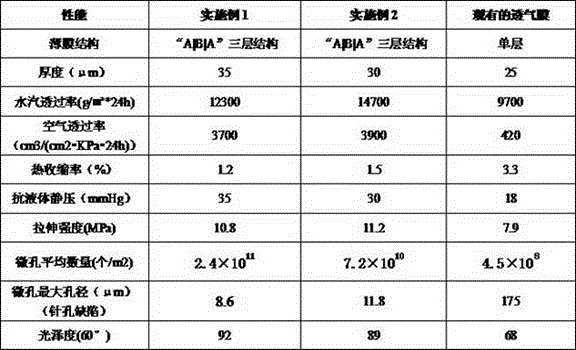

Examples

Embodiment 1

[0039] ①Put the components into a 110L internal mixer in proportion according to the following formula and knead for 24 minutes, then extrude through a Φ210 / Φ190 single-screw with a length-to-diameter ratio of 24:1, heat-cut granules after grinding, and obtain ultra-fine inorganic powder after air cooling Powder masterbatch:

[0040] LDPE 1F7B resin: 15 parts;

[0041] D97=4.6μm ultra-fine calcium carbonate powder: 95 parts;

[0042] Nengzhiguang E625 modifier: 6 parts;

[0043] KH550 dispersant: 5 parts;

[0044] Yanshan Petrochemical LP1000: 4 copies;

[0045] Mixing temperature zone 1 temperature Zone 2 temperature Zone 3 temperature Zone 4 temperature Head temperature Host speed Cutting speed 148℃ 135℃ 145℃ 150℃ 155℃ 150℃ 258r / min 125r / min

[0046] ②Put the components into a 200L high-speed mixer according to the following formula and stir for 5 minutes, then extrude through a Φ72 co-rotating twin-screw extruder with a length-to-...

Embodiment 2

[0073] ① According to the following formula, put the components into a 90L internal mixer in proportion and knead for 23 minutes, then extrude through a Φ160 / Φ145 single-screw with a length-to-diameter ratio of 26:1, grind and granulate, and air-cool to obtain ultra-fine inorganic Powder masterbatch:

[0074] LLDPE 7144 resin: 16 parts;

[0075] Talc powder with D97=2.5μm: 92 parts;

[0076] Nengzhiguang N408 modifier: 8 parts;

[0077] 1:1 mixture of aluminum isopropoxide and stearic acid: 5 parts;

[0078] 75# paraffin: 3 parts;

[0079] Mixing temperature zone 1 temperature Zone 2 temperature Zone 3 temperature Zone 4 temperature Head temperature Host speed Cutting speed 142℃ 130℃ 135℃ 135℃ 135℃ 140℃ 230r / min 110r / min

[0080] ②Put the components into a 200L high-speed mixer according to the following formula and stir for 5 minutes, then extrude through a Φ65 co-rotating twin-screw extruder with a length-to-diameter ratio of 40:1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com