An adhesive for polyurethane synthetic tracks and application thereof

A plastic track and adhesive technology, applied in polymer adhesive additives, non-polymer adhesive additives, roads, etc., can solve the problem of PU track glue not meeting environmental protection requirements, achieve a broad market application space, and improve traction. Tensile strength and elongation, toxicity reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

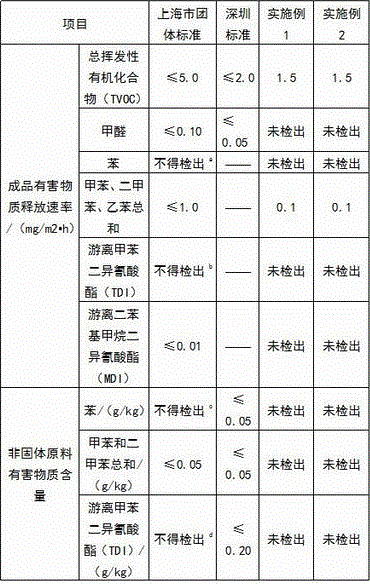

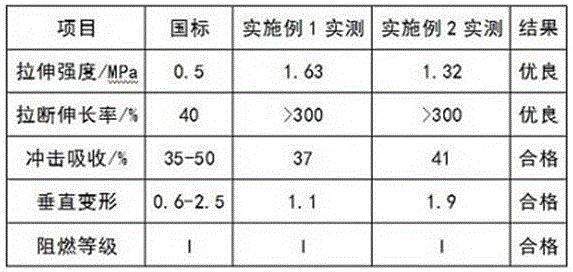

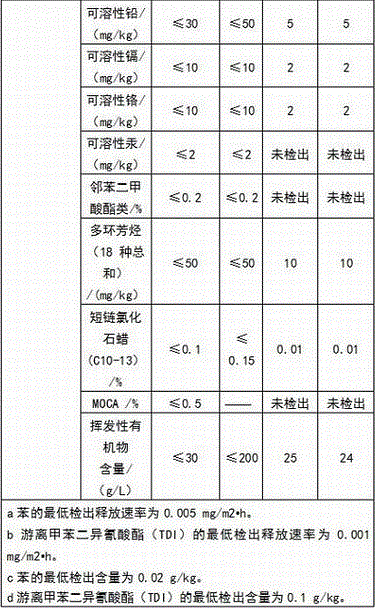

Examples

Embodiment 1

[0029] A. Preparation of component A (polyurethane prepolymer):

[0030] Vacuum dehydrate the polyether polyol mixture at 100°C for 2 hours, then cool to 50°C, calculate the ratio of polyether polyol and MDI required for component A with an NCO content of 9%, and then slowly add the measured MDI, the reaction temperature is controlled at 80-100°C, and the pressure is controlled at 4-6kg / cm 2 , the reaction time is 2-4 hours, until the hydroxyl groups in the system react completely;

[0031] B. Preparation of component B:

[0032] First mix 600g of mixed polyether polyol, 1100g of hydrochlorinated palm oil, and 150g of modified organic nano-montmorillonite, and use a planetary mixer or a high-shear homogeneous emulsifier to stir at high speed for 2 hours; then mix the mixed The colloid is added to the reactor, and the remaining 600g DINCH, 150g iron oxide red pigment, 50g DMTDA, 50g liquid HER, 250g titanium dioxide, 100g fumed silica, 1940g ultrafine talcum powder, 5g anti-u...

Embodiment 2

[0037] Example 2 700g mixed polyether, 1000g hydrochlorinated palm oil, 700g BENZOFLEX9-88, 100g modified organic nano-soil, 155g iron oxide red pigment, 60g DMTDA, 25g liquid HER, 150g fumed silica, 2100g superfine Talc powder, 5g anti-ultraviolet agent, and 5g antioxidant are formulated into 5kgB component according to the method described in Example 1 and synthesized track rubber sample block.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com