A kind of single-phase fluorescent powder for white light LED and preparation method thereof

A phosphor, a single technology, applied in the field of single-phase phosphor for white LED and its preparation, can solve the problems of low service life, low luminous efficiency, high energy consumption, etc., to reduce energy loss and improve luminous efficiency , The effect of simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

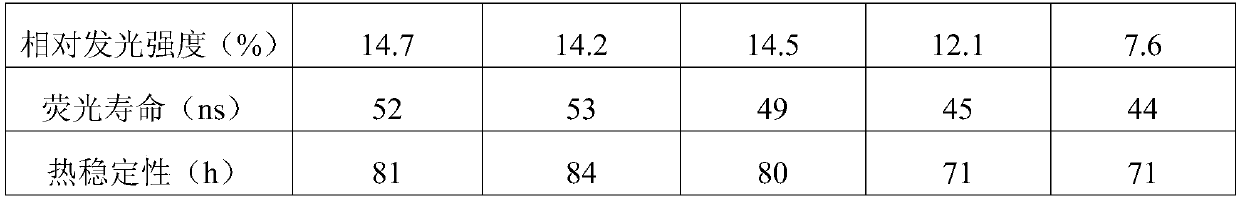

Embodiment 1

[0035]The single-phase phosphor powder for white light LED in this embodiment has a composition expression of Sr 0.9 MgSi 1.1 o 8 :(0.05Ce 3+ 0.06Dy 3+ ). The emission wavelength coverage of the phosphor powder is 450-650 nm, and the average particle size is 1-5 μm.

[0036] Prepare according to the following process:

[0037] (1) 1 part of Ce(NO 3 ) 3 , 1 part of Dy(NO 3 ) 3 , 1 part of Sr(NO 3 ) 2 Fully dissolved together to form a mixed solution with a mass fraction of 1%;

[0038] (2) immerse 100 parts of Na-montmorillonite with a purity of 99% in the mixed solution prepared in (1), and then fully dry at 150° C. to obtain a loaded powder;

[0039] (3) Calcining the loaded powder prepared in (2) at 400° C. for 1 h, then raising the temperature to 800° C. and calcining for 3 h to obtain single-phase phosphor A for white light LED.

Embodiment 2

[0041] The single-phase phosphor powder for white light LED in this embodiment has a composition expression of Sr 0.7 MgSi 1.4 o 8 :(0.03Ce 3+ 0.02Dy 3+ ). The emission wavelength coverage of the phosphor powder is 450-650 nm, and the average particle size is 1-5 μm.

[0042] Prepare according to the following process:

[0043] (1) 0.5 part of Ce(NO 3 ) 3 , 0.5 Ce 2 (SO 4 ) 3 , 0.5 parts Dy(NO 3 ) 3 , 0.5 Dy 2 (SO 4 ) 3 , 0.5 parts of Sr(NO 3 ) 2 , 0.5 parts of SrSO 4 Fully dissolved together to form a mixed solution with a mass fraction of 0.5%;

[0044] (2) 80 parts of Na-montmorillonite and 70 parts of Na-hectorite (the purity of Na-montmorillonite and Na-hectorite are all 99%) are jointly impregnated in the mixed solution prepared by (1), and then Fully dry at 200°C to obtain loaded powder;

[0045] (3) Calcining the supported powder prepared in (2) at 600° C. for 2 hours, then raising the temperature to 900° C. and calcining for 5 hours to obtain a sin...

Embodiment 3

[0047] The single-phase phosphor powder for white light LED in this embodiment has a composition expression of Sr 1.9 MgSi 1.5 o 8 :(0.06Ce 3+ 0.07Dy 3+ ). The emission wavelength coverage of the phosphor powder is 450-650 nm, and the average particle size is 1-5 μm.

[0048] Prepare according to the following process:

[0049] (1) 0.5 part of Ce(NO 3 ) 3 , 0.5 Ce 2 (SO 4 ) 3 , 0.5 parts CeCl 3 , 0.5 parts Dy(NO 3 ) 3 , 0.5 Dy 2 (SO 4 ) 3 , 0.5 parts of DyCl 3 , 0.5 parts of Sr(NO 3 ) 2 , 0.5 parts of SrSO 4 , 0.5 parts of SrCl 2 Fully dissolved together to form a mixed solution with a mass fraction of 1.5%;

[0050] (2) 100 parts of Na-montmorillonite and 100 parts of Na-hectorite (Na-montmorillonite and Na-hectorite purity are all 99%) are jointly impregnated in the mixed solution prepared in (1), and then Fully dry at 180°C to obtain loaded powder;

[0051] (3) Calcining the loaded powder prepared in (2) at 500° C. for 2 hours, then raising the temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com