A kind of cnts and cnfs synergistically reinforced copper matrix composite material and preparation method

A copper-based composite material and surface modification technology, applied in the field of composite materials, can solve the problems of easy aggregation and accumulation, difficult to evenly disperse, difficult to interface with

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Add CNTs to 10 μg / ml gallic acid aqueous solution and disperse evenly. The ratio of the weight of CNTs to the volume of gallic acid aqueous solution is 0.1g:40ml; let it stand for 24 hours, filter, and take the filter residue and dry it in vacuum at 60°C for 2 hours , to obtain surface-modified CNTs.

[0057] Evenly disperse 0.1 g of the surface-modified CNTs prepared in this example in 100 ml of deionized water, and after standing for 3 days, the precipitation gradually increases under the action of gravity, but the CNTs still maintain a dispersed state without agglomeration; at the same time Compared with unmodified CNTs, precipitation occurred after standing for 1 day, and agglomeration occurred among CNTs, indicating that the surface-modified CNTs prepared in Example 1 had excellent dispersibility.

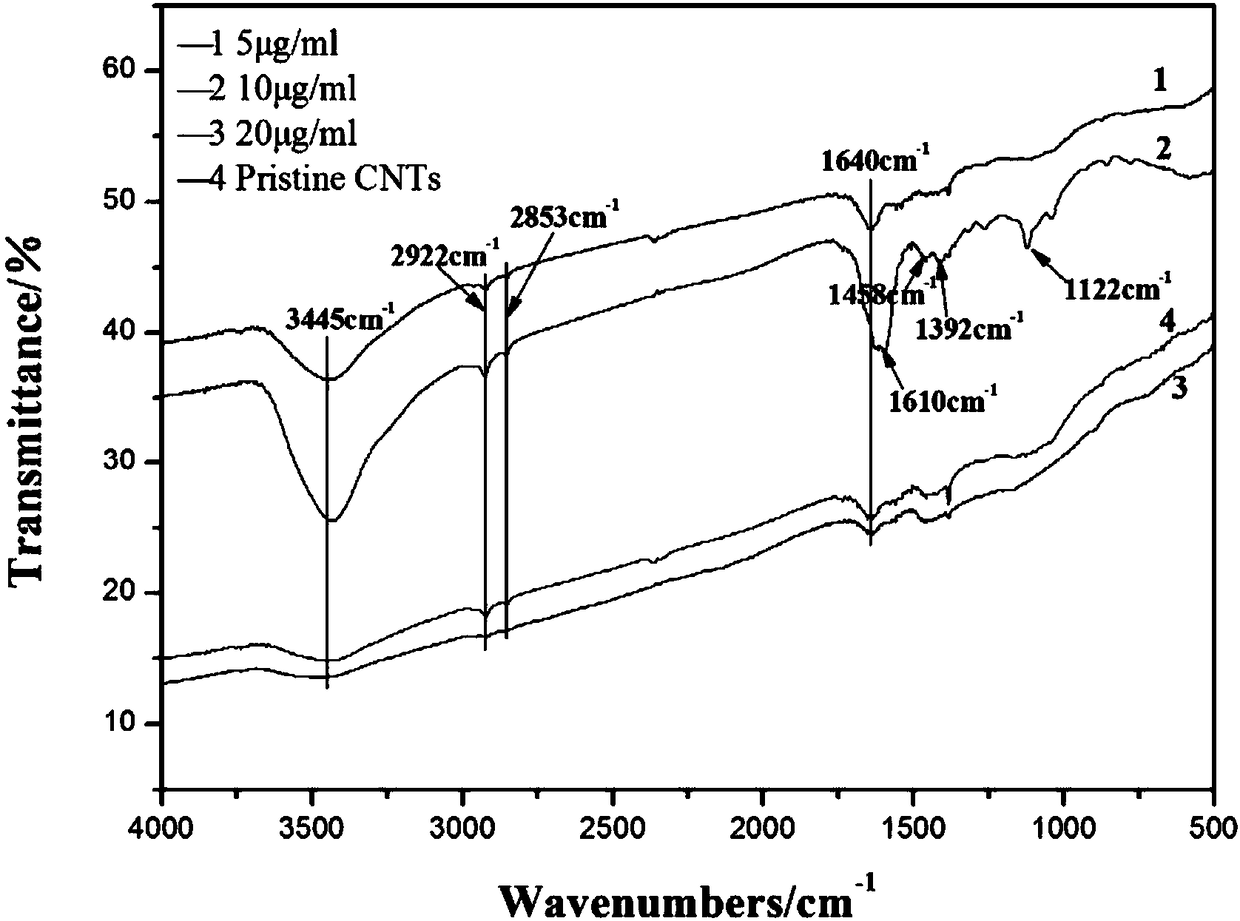

[0058] Using the above-mentioned method, the modified carbon nanotubes were prepared by successively using gallic acid aqueous solutions with a concentration of 5 μg / ml...

Embodiment 2

[0062] Add CNFs to 0.02 μg / ml rutin aqueous solution and disperse evenly. The ratio of the weight of CNFs to the volume of rutin aqueous solution is 0.1g:40ml; let stand for 24h, filter, and take the filter residue and dry it in vacuum at 60°C for 2h , to obtain surface-modified CNFs.

[0063] Evenly disperse 0.1 g of the surface-modified CNFs prepared in Example 2 in 100 ml of deionized water. After standing for 5 days, the precipitation gradually increases under the action of gravity, but the CNFs still maintain a dispersed state without agglomeration; At the same time, compared with unmodified CNFs, precipitation occurred after standing for 1 day, and agglomeration occurred between CNFs, indicating that the surface-modified CNFs prepared in Example 2 had excellent dispersibility.

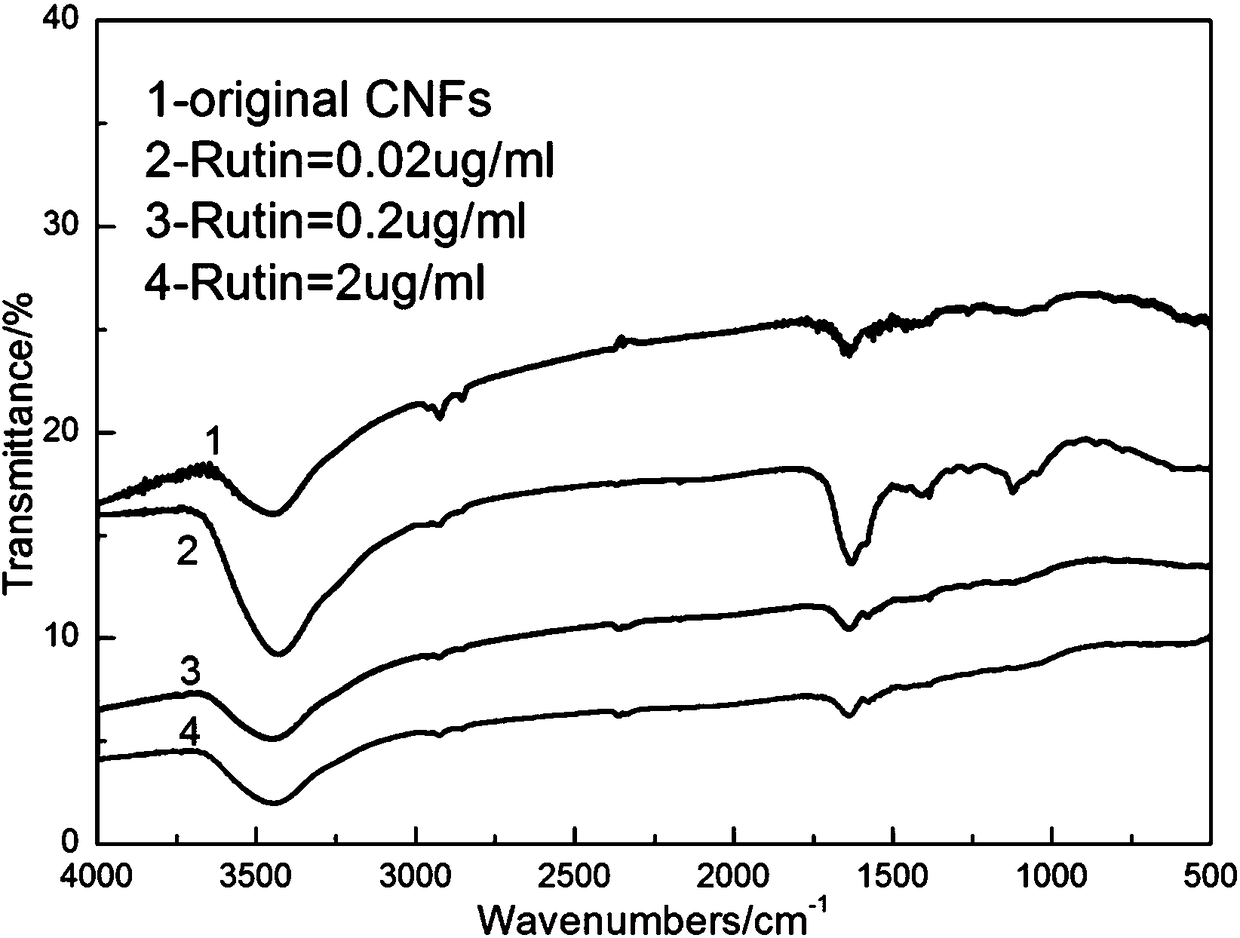

[0064] Using the above method, the modified graphene (CNFs) was prepared sequentially with rutin aqueous solutions with concentrations of 0.2 μg / ml and 2 μg / ml, and the Fourier transform infrared...

Embodiment 3

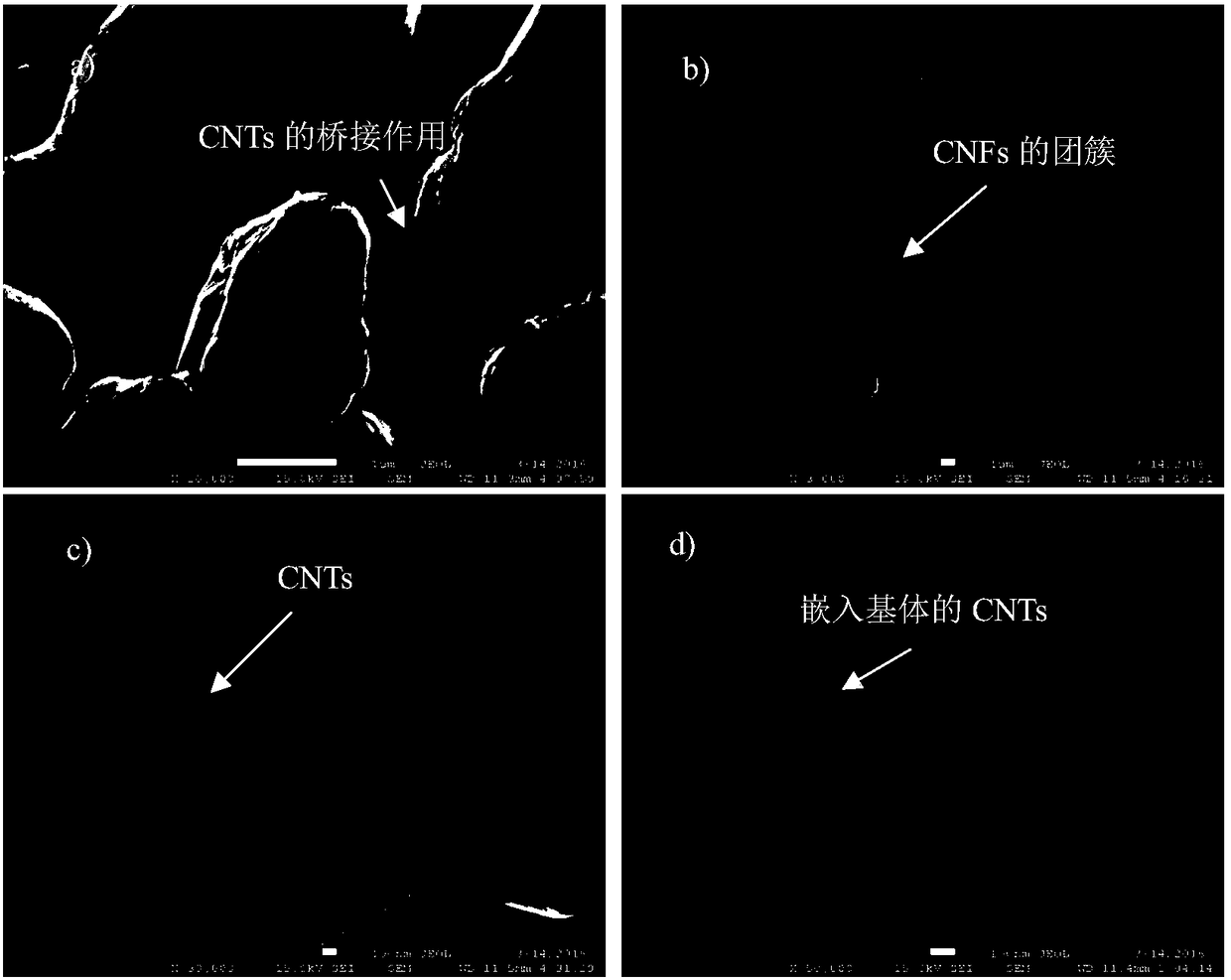

[0067] (1) Take the surface-modified CNTs and surface-modified CNFs prepared in Example 1 and Example 2 (both are the modified CNTs and modified CNFs with the best performance prepared in Example 1-2, That is, 10 μg / ml gallic acid, 0.02 μg / ml rutin-modified CNTs and CNFs, the following examples are the same); (2) By weight, 0.8 parts of CNTs and 0.2 parts of CNFs, 3 parts graphite powder, 10 parts Ti 3 SiC 2 powder, 0.1 parts of La powder and 85.9 parts of copper powder were mixed by ball milling, the speed of rotation was 200 rpm, and the ball milling time was 50 minutes, so that the powders were mixed evenly to obtain a composite powder; (3) The composite powder was hot-pressed and sintered for 2 hours, and then The temperature of pressure sintering is 950°C, the pressure is 28MPa, and the copper-based composite block material is obtained by cooling with the furnace; (4) The obtained block material is subjected to hot isostatic pressing for 2 hours, and the hot isostatic pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com