Polyacrylonitrile/copper sulphide photo-thermal nanofiber fabric and production method and application thereof

A nanofiber, polyacrylonitrile technology, applied in the direction of fiber type, fiber treatment, fiber chemical characteristics, etc., can solve the problems of difficult popularization and wide application, slow heating rate, limited heat, etc., to save energy consumption, huge Application value, effect of wide light absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

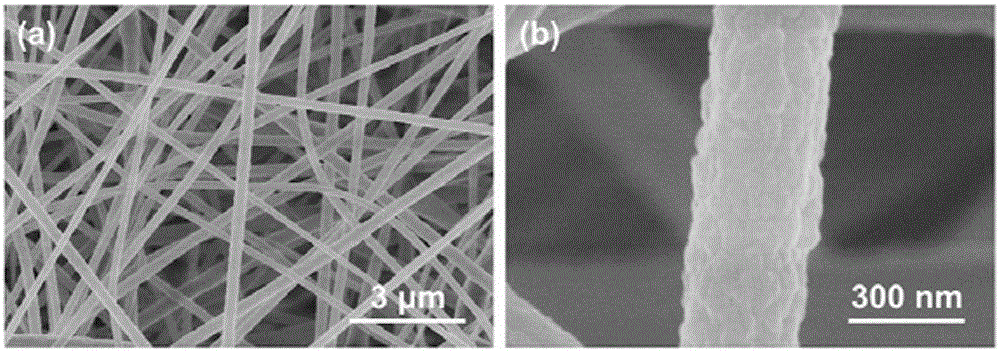

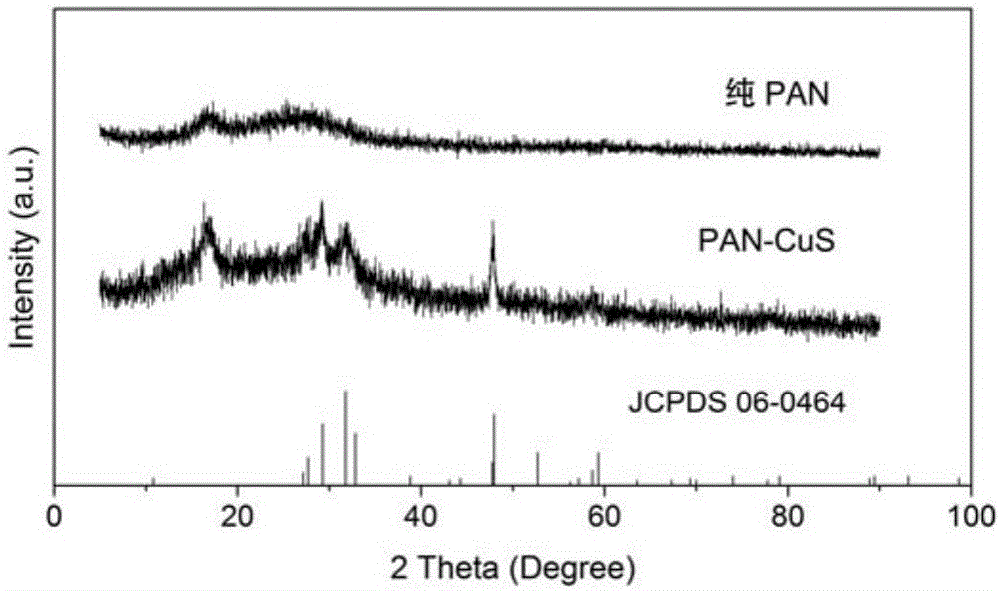

[0033] Weigh 2.1 g of polyacrylonitrile with an analytical balance, add it into a round-bottomed flask filled with 30 ml of organic solvent DMF, put it into a heating mantle, set the temperature at 60° C., and stir magnetically overnight to dissolve. The next day, 0.2658 g of Cu(C) was added to the resulting PAN solution. 5 h 7 o 2 ) 2 , after dissolving evenly, let stand to defoam, and obtain an opaque blue-purple spinning stock solution. Take 10mL of spinning stock solution into a syringe for electrospinning, set the spinning temperature at 50°C, spinning voltage at 16.91kV, injection speed at 45μL / min, relative humidity at about 25%, and use aluminum foil to collect nano fiber, the receiving distance is 20cm, and the copper-containing PAN nanofiber cloth is obtained, from figure 1 It can be seen that the diameter distribution of these nanofibers is relatively uniform, and the average diameter is between 300 and 350 nm.

Embodiment 2

[0036] Weigh 1.4 g of polyacrylonitrile with an analytical balance, add it into a round-bottom flask filled with 20 ml of organic solvent DMF, put it into a heating mantle, set the temperature at 60° C., and stir it overnight with magnetic force to dissolve. The next day, 0.1329 g of Cu(C) was added to the resulting PAN solution. 5 h 7 o 2 ) 2 , after dissolving evenly, let stand to defoam, and obtain an opaque blue-purple spinning stock solution. Take 20mL of spinning stock solution into a syringe for electrospinning, set the spinning temperature at 35°C, spinning voltage at 16.08kV, injection speed at 35μL / min, relative humidity at about 25%, and use aluminum foil to collect nano fiber, the receiving distance is 15cm, and the copper-containing PAN nanofiber cloth is obtained.

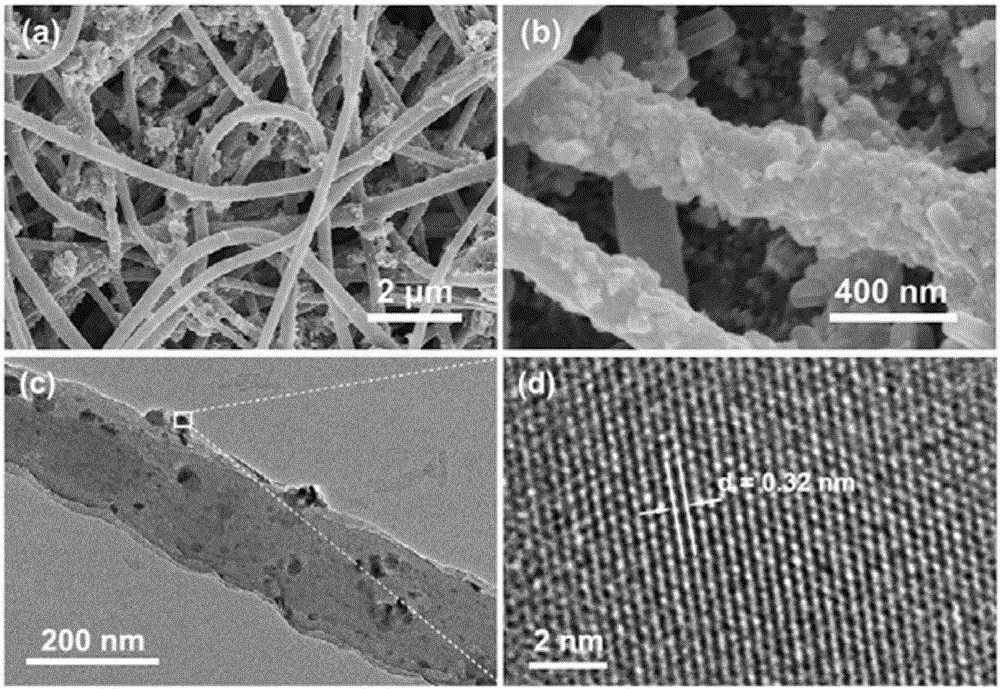

[0037] Use a pipette gun to measure 0.9ml of ammonium sulfide solution (mass percentage of sulfur element ≥ 8%) and add it to 45mL of deionized water to form a 0.05mol / L sodium sulfide solution. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com